Extraction method for astragalus polysacharin

A technology of astragalus polysaccharide and extraction method, which is applied in the field of extracting polysaccharides and astragalus polysaccharides by using low-temperature liquid nitrogen crushing combined with polysorbate-80-assisted plant compound enzymatic hydrolysis, and can solve the problems of unstable properties of polysaccharides, low extraction rate, and high cost. problems, achieve the effects of shortening pretreatment and extraction time, improving nutrition, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

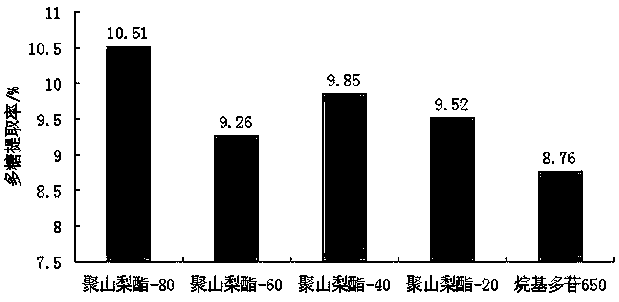

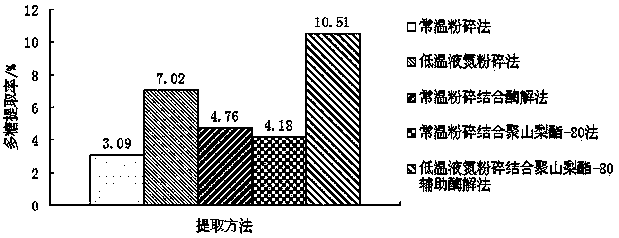

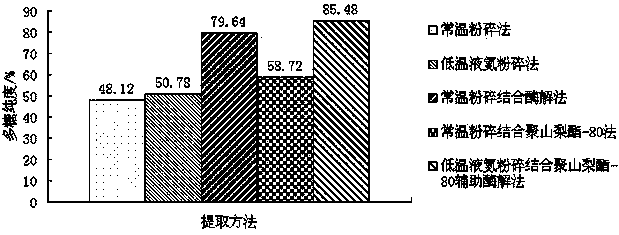

Examples

Embodiment 1

[0032] A method for extracting astragalus polysaccharides, comprising the steps of:

[0033] Pretreatment: remove impurities such as mud and sand on the roots of Astragalus mongolica;

[0034] S1. the root of Astragalus mongolica is crushed through low-temperature liquid nitrogen; Astragalus powder is obtained after crossing an 80-mesh sieve; in the crushing process of the low-temperature liquid nitrogen, the feed rate of nitrogen gas is 3mL / s, and the feed rate of Radix Astragali is 4g / s; the crushing temperature -5°C;

[0035] S2. Treat 3 parts of astragalus powder, 12 parts of sterile water, 0.3 parts of polysorbate-800, 0.3 parts of cellulase, and 0.1 part of pectinase at 60°C and pH 4.8 for 1.5 hours; Parts are parts by weight;

[0036] S3. Inactivate the enzyme at 100°C for 15 minutes; then extract at 85°C for 2.5 hours; filter; concentrate for 60 minutes at a vacuum of 95kPa and a concentration temperature of 60°C to obtain a concentrated solution; add 95% ethanol 5 t...

Embodiment 2

[0038] A method for extracting astragalus polysaccharides, comprising the steps of:

[0039] Pretreatment: remove impurities such as mud and sand on the roots of Astragalus mongolica;

[0040] S1. the root of Astragalus mongolica is crushed through low-temperature liquid nitrogen; Astragalus powder is obtained after crossing an 80-mesh sieve; in the crushing process of the low-temperature liquid nitrogen, the feed rate of nitrogen gas is 3mL / s, and the feed rate of Radix Astragali is 4g / s; the crushing temperature -5°C;

[0041] S2. Treat 3 parts of astragalus powder, 12 parts of sterile water, 0.3 parts of polysorbate-600, 0.3 parts of cellulase, and 0.1 part of pectinase at 60°C and pH 4.8 for 1.5 hours; Parts are parts by weight;

[0042] S3. Inactivate the enzyme at 100°C for 15 minutes; then extract at 85°C for 2.5 hours; filter; concentrate for 60 minutes at a vacuum of 95kPa and a concentration temperature of 60°C to obtain a concentrated solution; add 95% ethanol 5 t...

Embodiment 3

[0044] A method for extracting astragalus polysaccharides, comprising the steps of:

[0045] Pretreatment: remove impurities such as mud and sand on the roots of Astragalus mongolica;

[0046] S1. the root of Astragalus mongolica is crushed through low-temperature liquid nitrogen; Astragalus powder is obtained after crossing an 80-mesh sieve; in the crushing process of the low-temperature liquid nitrogen, the feed rate of nitrogen gas is 3mL / s, and the feed rate of Radix Astragali is 4g / s; the crushing temperature -5°C;

[0047] S2. Treat 3 parts of astragalus powder, 12 parts of sterile water, 0.3 parts of polysorbate-400, 0.3 parts of cellulase, and 0.1 part of pectinase at 60°C and pH 4.8 for 1.5 hours; Parts are parts by weight;

[0048] S3. Inactivate the enzyme at 100°C for 15 minutes; then extract at 85°C for 2.5 hours; filter; concentrate for 60 minutes at a vacuum of 95kPa and a concentration temperature of 60°C to obtain a concentrated solution; add 95% ethanol 5 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com