Method for femtosecond laser etching glass based on electronic dynamic regulation and control

An electronic dynamic control, femtosecond laser technology, applied in the field of femtosecond laser applications, can solve the problems of limited capacity, low etching efficiency, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

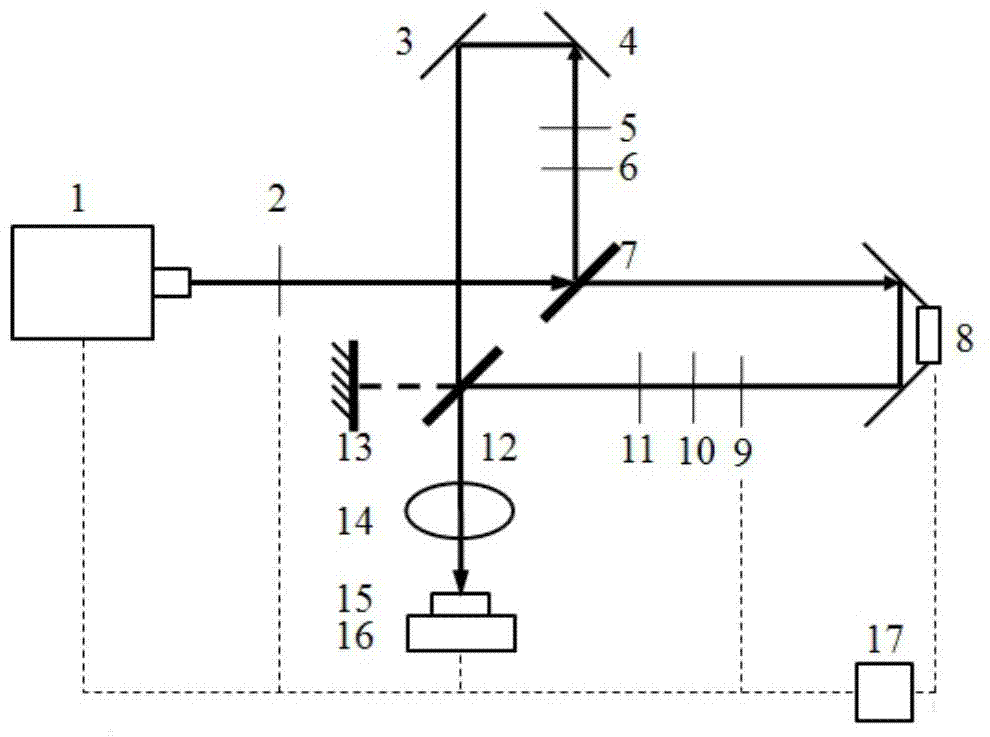

[0020] Firstly, the traditional femtosecond laser pulse was used to irradiate the modification, and the etching efficiency was calculated. The etching efficiency was defined as the length of the etched micropore per unit time. The specific processing steps are as follows:

[0021] (1) Turn on the first mechanical switch 2 and turn off the second mechanical switch 9. At this time, only the sub-pulse light I is used for processing, and the optical path is adjusted to ensure that the laser incident direction is perpendicular to the surface of the processed sample;

[0022] (2) By adjusting the first half-wave plate 6 and the polarizer 5, the energy of the sub-pulse light I is adjusted to 2 μJ; the energy of the sub-pulse light I is reflected by the beam combiner 12 to 1 / 2, and actually acts on the sample The laser energy is 1μJ, the focused spot diameter is about 6μm, and the energy density is about 3.5J / cm 2 .

[0023] (3) The computer 17 controls the mobile platform 16 to mov...

Embodiment 2

[0026] The following takes femtosecond laser double pulse as an example to illustrate the effect of etching enhancement after femtosecond laser double pulse irradiation modification.

[0027] The method for improving the etching efficiency of glass materials by using femtosecond laser double pulses proposed by the present invention, the specific processing steps are as follows:

[0028] (1) Turn on the first mechanical switch 2 and the second mechanical switch 9 respectively, adjust the optical path, and ensure that the incident direction of the laser is perpendicular to the surface of the processed sample;

[0029] (2) By adjusting the first half-wave plate 6 and the first polarizer 5, adjust the energy of the sub-pulse light I to 0.5 μJ; by adjusting the second half-wave plate 10 and the second polarizer 11, adjust the energy of the sub-pulse light II The energy is adjusted to 1.5 μJ; at this time, because of the reflection of the beam combiner 12, the total energy actually ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com