Seasoning method and etching method

A warm-up and chamber technology, which is used in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve the problem of process gas photoresist accompanying film and excessive power, reduce the efficiency of plasma processing equipment, and increase production costs. and other problems to achieve the effect of reducing costs, improving efficiency and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

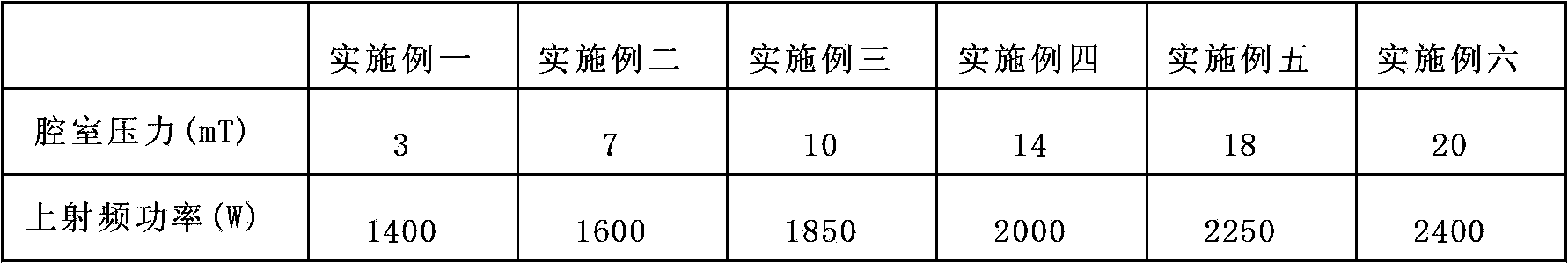

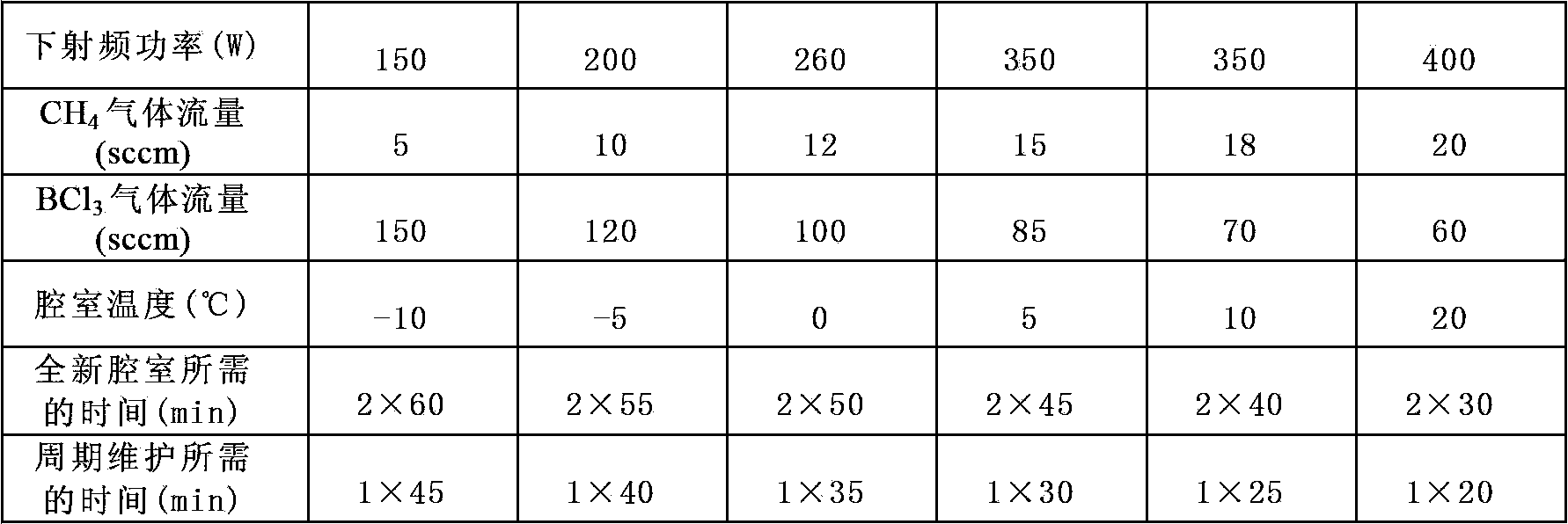

Examples

Embodiment Construction

[0029] In order to make those skilled in the art better understand the technical solution of the present invention, the warm-up method provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0030] In this embodiment, an inductively coupled plasma etching process is used to etch a photoetched substrate, and the substrate may be a silicon wafer or other materials such as sapphire. Before etching the substrate, a warm-up process is performed to make the environment inside the chamber reach the working state required for etching the substrate. Moreover, since the substrate is covered by photoresist, forming a polymer close to the composition of the photoresist on the inner wall of the chamber is conducive to improving the selectivity of etching, that is, covering the surface of the inner lining of the chamber with a polymer can make The environment inside the chamber reaches the working state required for etching the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com