Method of treating traditional Chinese medicine wastewater by utilizing modified fly ashes and photocatalyst

A technology of photocatalyst and fly ash, which is applied in chemical instruments and methods, energy wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of long time consumption, large floor area, unfavorable bacterial group survival, etc., and achieve convenience Storage and transportation, realizing recycling and shortening the treatment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

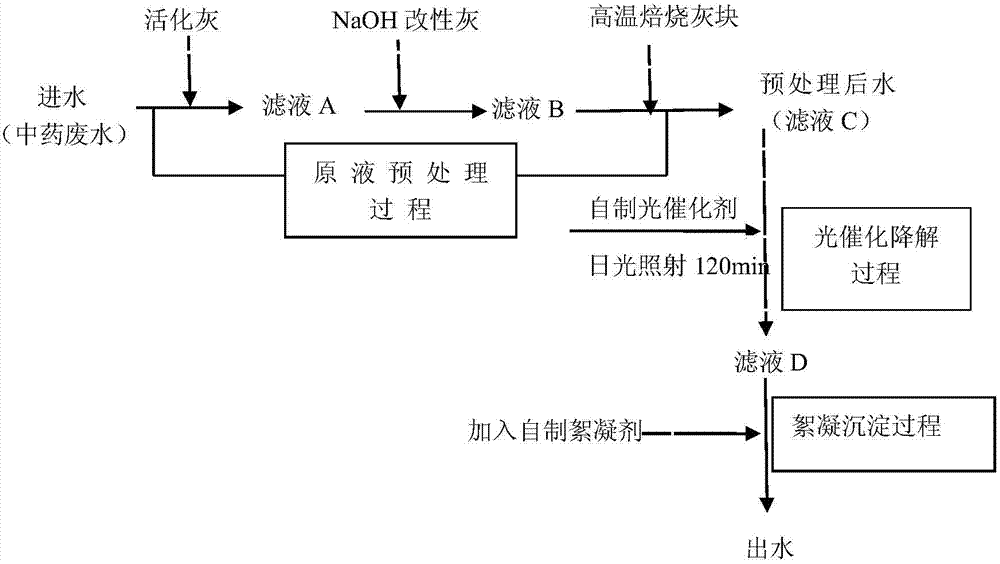

Method used

Image

Examples

Embodiment 1

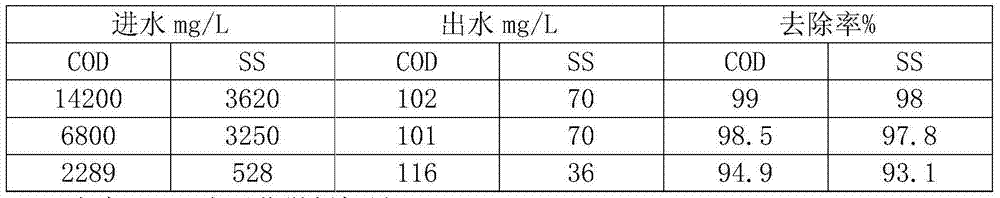

[0020]The mixed production wastewater of a traditional Chinese medicine pharmaceutical factory in Inner Mongolia is used. During the production of traditional Chinese medicine in this pharmaceutical factory, the mixed production wastewater is mainly composed of traditional Chinese medicine production wastewater, bottle washing, rubber stopper washing wastewater, resin regeneration wastewater, machine repair wastewater, domestic wastewater, quality inspection wastewater, It consists of seven types of wastewater, including the raffinate recovered by ethanol distillation. Wastewater is yellowish brown, COD Cr (Chemical oxygen demand measured by potassium dichromate method) average value is 14200mg / L, SS (represents suspended solid particles) average value is 3620mg / L, average pH value is 4.5, and the absorbance of wastewater at 340nm is 0.523. The main chemical composition of the fly ash used is SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, NaO, and unburned carbon, etc., where the...

Embodiment 2

[0027] The waste water produced in the processing of traditional Chinese medicine in a hospital of traditional Chinese medicine in Inner Mongolia is mainly used for washing and irrigation. Wastewater is yellowish brown, COD Cr (Chemical oxygen demand measured by potassium dichromate method) average value is 6800mg / L, SS (represents suspended solid particles) average value is 3250mg / L, average pH value is 5.1, and the absorbance of wastewater at 340nm is 0.535. The powder used The main chemical composition of coal ash is SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, NaO, and unburned carbon, etc., where the mass fractions of active ingredients are SiO 2 40%, Al 2 o 3 17%, and Fe 2 o 3 15%.

[0028] Using the method of the present invention, the traditional Chinese medicine wastewater is sequentially subjected to stock solution pretreatment, photocatalytic degradation, and flocculation and sedimentation treatment. The detailed process is as follows:

[0029] (1) Stock soluti...

Embodiment 3

[0034] The waste water produced in the processing of traditional Chinese medicine in a pharmacy in Baotou, Inner Mongolia is used, including washing liquid and washing water. Wastewater is yellowish brown, COD Cr (Chemical oxygen demand measured by potassium dichromate method) average value is 2289mg / L, SS (represents suspended solid particles) average value is 528mg / L, average pH value is 5, and the absorbance of wastewater at 340nm is 0.559. The powder used The main chemical composition of coal ash is SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, NaO, and unburned carbon, etc., where the mass fractions of active ingredients are SiO 2 55%, Al 2 o 3 30%, and Fe 2 o 3 6%.

[0035] Using the method of the present invention, the traditional Chinese medicine wastewater is sequentially subjected to stock solution pretreatment, photocatalytic degradation, and flocculation and sedimentation treatment. The detailed process is as follows:

[0036] (1) Stock solution pretreatment: T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com