Adsorption flow grinding and polishing method

A technology of adsorption instrument and adsorption tube, which is applied in the field of polishing, can solve problems such as unusable, low processing efficiency, and immature technology, and achieve the effect of easy surface repair, convenient realization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

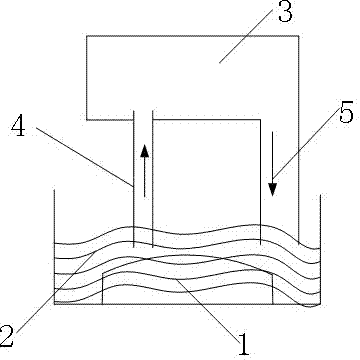

[0028] As shown in Figure 1, this embodiment provides an adsorption flow grinding and polishing method, which does not require a grinding head, and the friction force generated by the flow of the starch mixture and the surface of the processing element replaces the grinding force to perform grinding. Specifically, the polishing method includes the following steps:

[0029] 1. Soak the component to be processed 1 into the starch mixture 2, and the liquid surface submerges the processing component;

[0030] 2. Extend the adsorption tube 4 connected with the adsorption instrument 3 below the surface of the starch mixture, and the nozzle of the adsorption tube is 0.5mm to 1mm away from the processing element. Preferably, the nozzle of the adsorption tube is 1mm away from the processing element; the adsorption instrument is a vacuum cleaner. Or suction pump, power 1500W, vacuum suction 1900MM, air flow 53L / S, adsorption tube diameter 36mm;

[0031] 3. Fix the adsorption tube, turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com