Last billet clamping mechanism of numerical control (NC) last making machine

A technology of clamping mechanism and last-carving machine, which is applied to wood processing appliances, manufacturing tools, etc., can solve the problem of not being able to complete the processing of shoe lasts at one time, and achieve the effects of compact structure, improved processing efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given together with the accompanying drawings and described in detail as follows.

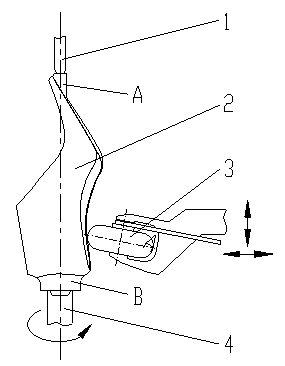

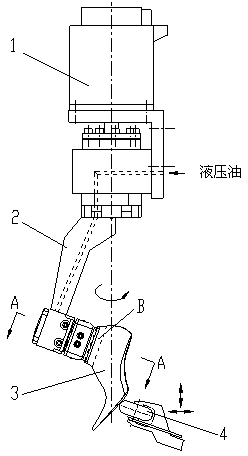

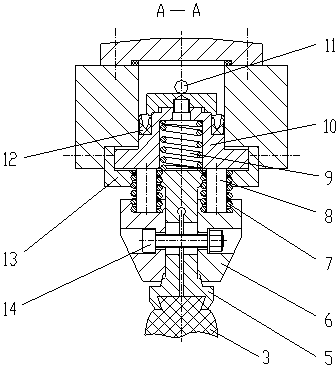

[0015] The last blank holding mechanism designed by the five-axis CNC last engraving machine is as follows: Figure 2~3 As shown, the servo motor 1 drives the clamping arm 2 through the connecting part to clamp the last blank tube B through the clamping claw 5 to drive the last blank 3 to rotate around the center of rotation, and completes the processing of the shoe last under the action of the cyclone knife 4. The blank clamping method can complete the CNC carving at one time, which solves the defect that the two ends of the last blank cannot be clamped at one time to complete the shoe last processing. The last blank clamping mechanism of the numerical control last engraving machine of the present invention includes a clamping arm 2, which is cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com