Curved surface turbulence polishing device with multiple outlets and inlets

A technology with multiple entrances and exits and polishing devices, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., to achieve uniform flow, high polishing precision, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

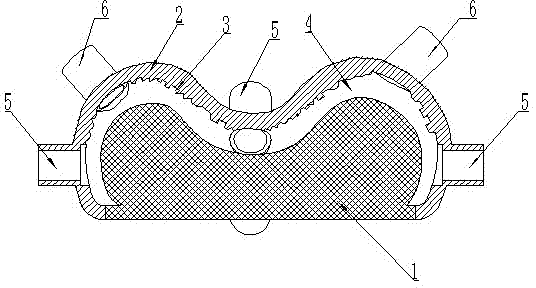

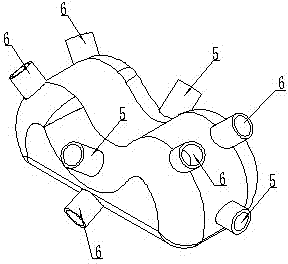

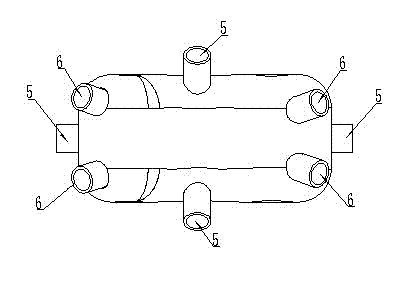

[0014] to combine Figure 1~3 , a curved surface turbulent polishing device with multiple inlets and outlets, including a restraint member 2, which is set outside the artificial joint 1, the inner surface of the restraint member 2 is the same shape as the outer surface of the artificial joint 1, and the inner surface of the restraint member 2 and the outer surface of the artificial joint 1 form a The contoured flow channel 4 is provided with micro grooves 3 on the inner surface of the constraining member 2 , the micro grooves 3 are irregular, and the micro grooves 3 are evenly distributed on the inner surface of the constraining member 2 .

[0015] There are two inflection points and one singular point on the surface of the artificial joint 1, that is, the protruding part and the concave part on the surface of the artificial joint 1, which are sudden changes in the curved surface, and the abrasive particle inflow and outflow inlets are evenly distributed on the constraining mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com