Engineering construction method and construction equipment for transparent concrete

A construction method and concrete technology, applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of easy slippage of optical fibers, heavy workload, slow operation, etc., and achieve fast optical fiber laying, convenient construction and operation, and fast preparation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

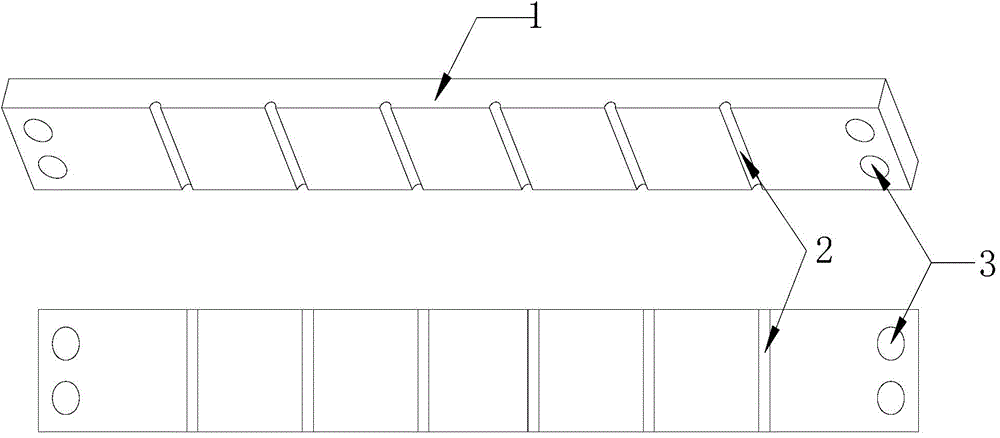

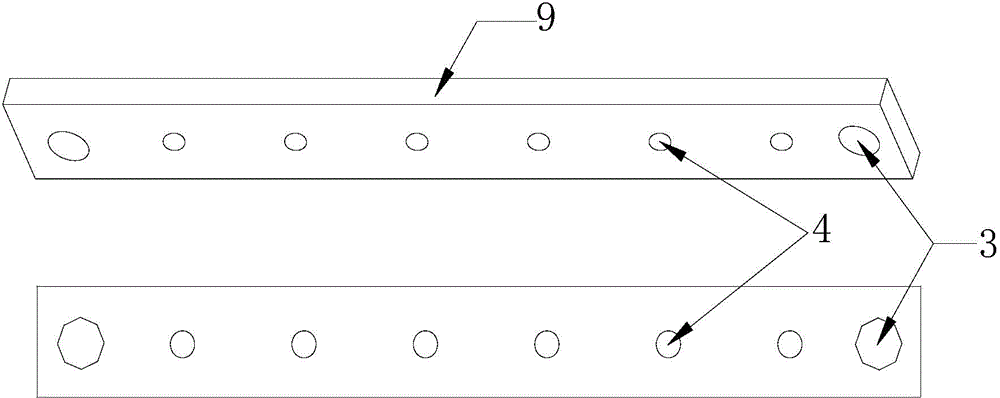

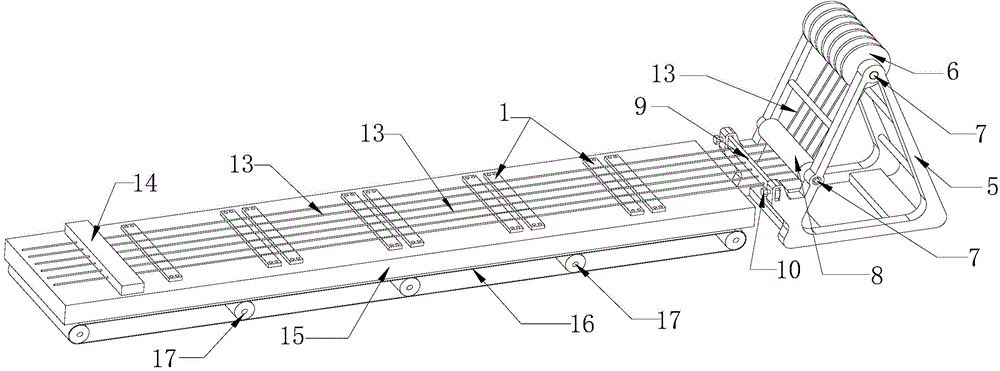

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. The parts of the present invention that belong to the general technology are briefly described, and the structures and construction dimensions shown in the figures are not restrictive. In order to facilitate an intuitive understanding of the present invention, the physical dimensions, proportional relationships, etc. in the drawings are for reference only, and the equipment dimensions can be made according to individual needs.

[0035] Examples of transparent concrete construction methods and construction equipment:

[0036] The key production process of transparent concrete is how to quickly and evenly arrange optical fibers, which is also a major unsolved problem at present. In order to achieve the purpose of efficiently and quickly laying optical fibers and realizing the large-scale industrial production of transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com