Process for producing shaping plates by using waste paper, plates and waste plastics

A production process and waste plastic technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of forest disappearance, deterioration of the global climate and environment, waste of resources, etc., to achieve a simple process path, high product commercial value, and equipment investment. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

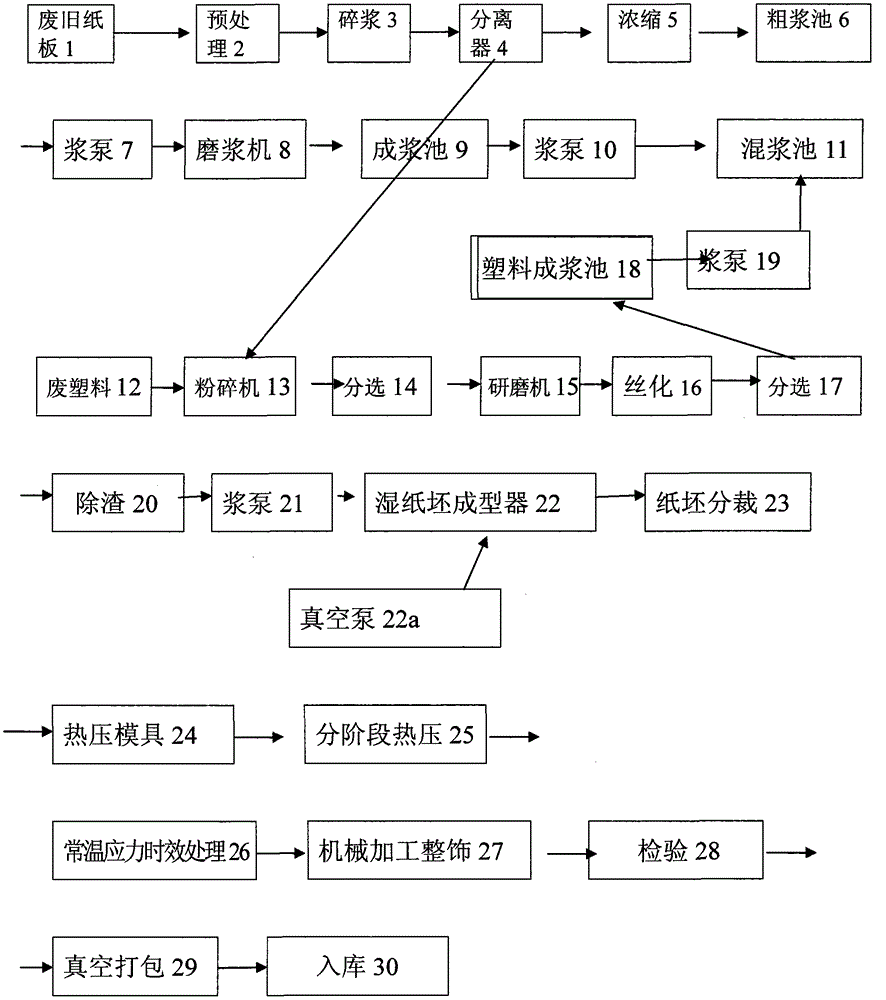

[0009] Example 1, such as figure 1 As shown, a production process of using waste paper, board and waste plastics to make templates, the waste paper and board 1 are pulverized by a shredder 13, purified and pretreated 2, and then pulped 3, and the crushed pulp is passed through Separator 4 sorts, the sorted pulp is concentrated 5 to a concentration of 3.5% and enters the coarse stock pool 6, and the pulp is sent to the refiner 8 through the pulp pump 7, and is ground into a pulp liquid with a knocking degree of 35°SR and a wet weight of 7g , the ground slurry is sent into the slurry tank 9, and then sent into the slurry mixing tank 11 by the slurry pump 10;

[0010] After the waste plastics 12 and the plastics separated by the separator 4 are pulverized by the pulverizer 13, they are sent to the sorting screen 14 for sorting, and the pulverized plastic particles are sent to the grinder 15 for grinding and refining, and the ground plastic sheets and fine particles are passed thr...

Embodiment 2

[0011] Example 2, such as figure 1 As shown, a production process of using waste paper, boards and waste plastics to make templates, the waste paper and boards are pulverized by a shredder 13, purified and pretreated 2, and then pulped 3, and the crushed pulp is separated Classification by the device 4, the classified pulp is concentrated 5 to a concentration of 3.5% and enters the coarse stock pool 6, and the pulp is sent to the refiner 8 through the pulp pump 7, and is ground into a pulp liquid with a knocking degree of 41°SR and a wet weight of 11g. Send the ground slurry into the slurry tank 9, and then send it into the slurry mixing tank 11 through the slurry pump 10;

[0012] After the waste plastics 12 and the plastics separated by the separator 4 are pulverized by the pulverizer 13, they are sent to the sorting screen 14 for sorting, and the pulverized plastic particles are sent to the grinder 15 for grinding and refining, and the ground plastic sheets and fine particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com