(SrCa)TiO3-LaAlO3-based microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and base materials, which is applied in the field of high quality factor microwave dielectric ceramic materials and microwave dielectric ceramic materials. It can solve the problems of microwave dielectric ceramic performance deterioration, high sintering temperature requirements, and microwave performance deterioration. Improvement, stable performance, and excellent microwave dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

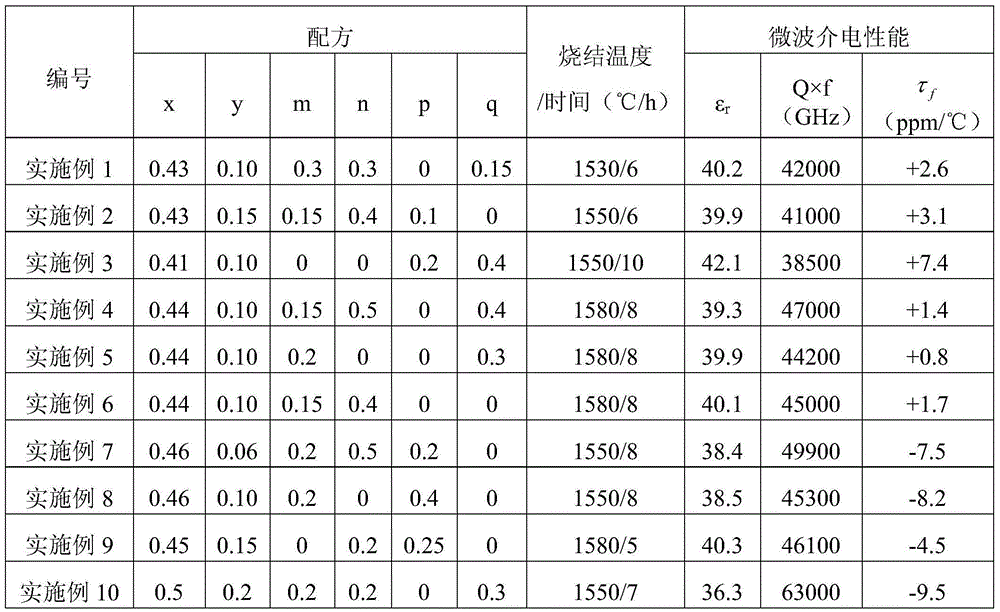

Embodiment 1~10

[0028] The concrete implementation steps that make these embodiment microwave dielectric ceramics are as follows:

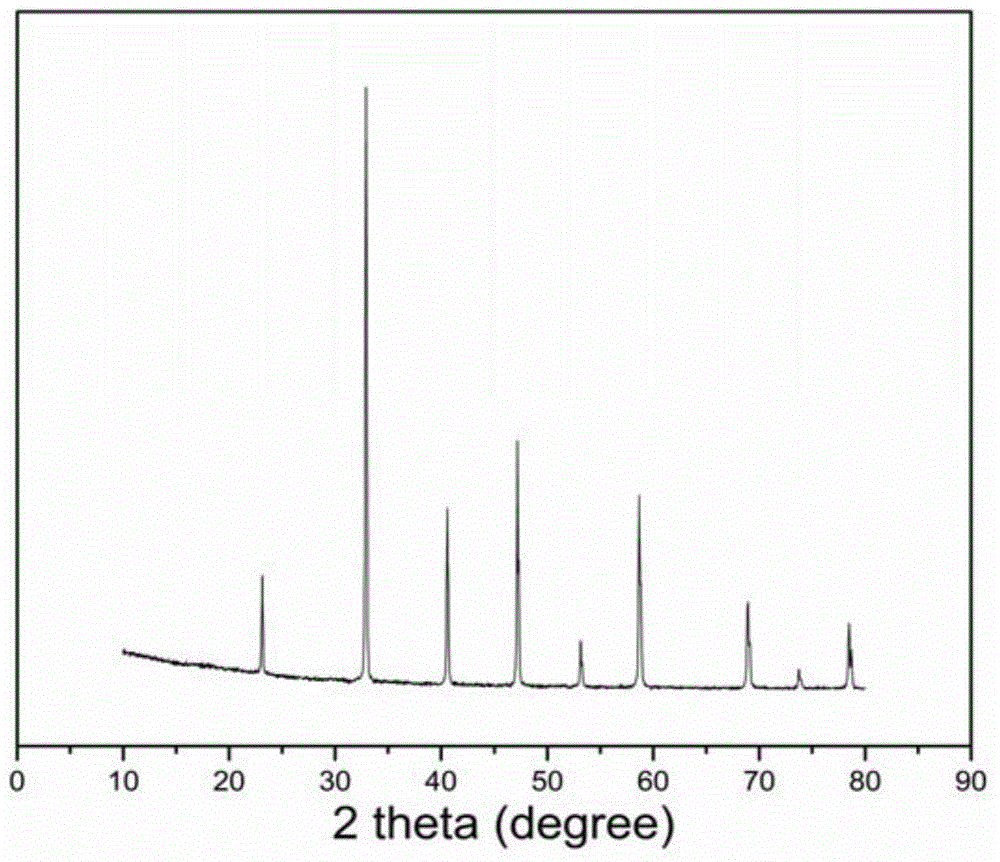

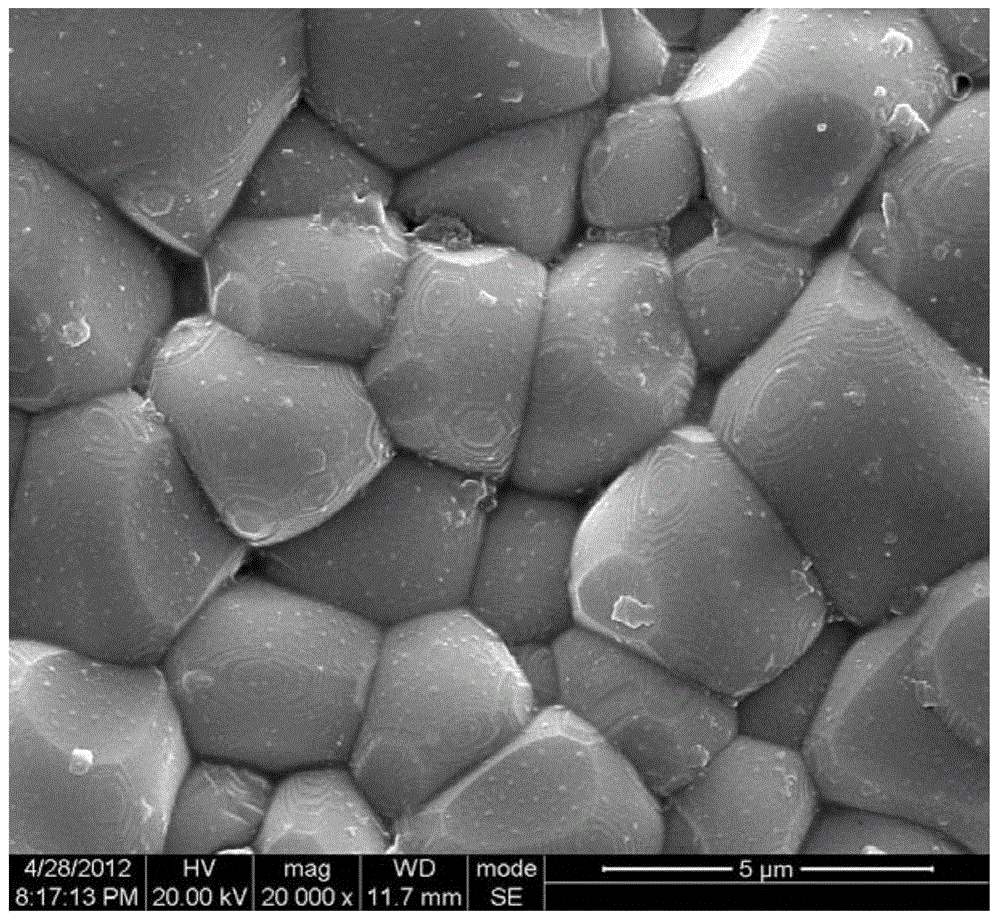

[0029] (1) Synthesis of base material: SrCO with purity ≥ 99% 3 , CaCO 3 , La 2 o 3 、Al 2 o 3 and TiO 2 As a raw material, according to the chemical composition formula (1-x)Sr (1-y) Ca y TiO 3 -xLaAlO 3 (wherein 0.40≤x≤0.50, 0.05≤y≤0.20) molar ratio is carried out batching, and specific formula is shown in Table 1; Put the above-mentioned mixed material into the nylon ball mill jar, and use zirconium ball as grinding ball, in the past Ionized water is used as the ball milling medium, the ratio of the added material to the zirconium ball is 1:5, and the ball milling time is 5 to 8 hours. After the ball milling, the slurry is taken out and dried at 100°C and passed through a 60-mesh sieve to obtain Primary ball grinding material, pre-calcining the primary ball grinding material at a temperature of 1250 ° C to 1350 ° C for 3 to 5 hours to obtain a pre-fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com