Long-chain alkyl polyamine series asphalt anti-stripping agent and preparation method thereof

A technology of anti-stripping agent and alkyl polyamine, which is applied in the field of building materials and civil engineering materials, can solve the problems of insufficient hydrolysis resistance, harsh reaction conditions, migration and loss, etc., and achieve good anti-stripping ability, mild synthesis conditions, and simplified The effect of the process step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

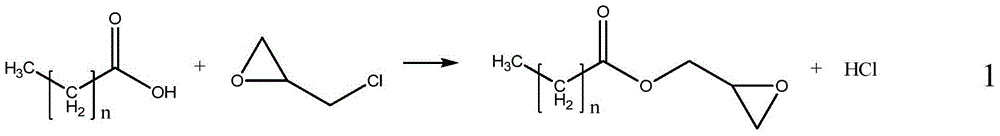

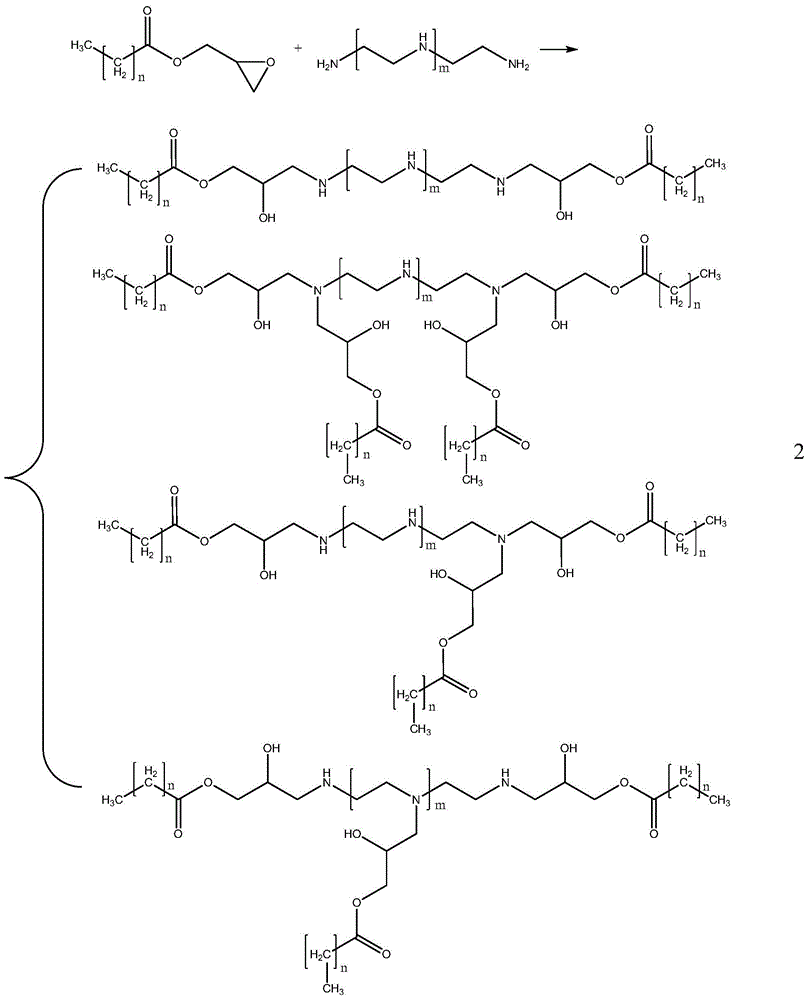

Method used

Image

Examples

Embodiment 1

[0025] The long-chain alkyl polyamine series asphalt anti-stripping agent of this embodiment, the raw material of the anti-stripping agent includes the following components by weight: 0.6 part of long-chain alkyl organic acid, 0.3 part of epichlorohydrin, and 0.1 part of organic amine.

[0026] In this embodiment, the organic amine is diethylenetriamine. In this embodiment, the diethylenetriamine is replaced by ethylenediamine, triethylenetetramine, tetraethylenepentamine, polyethylenepolyamine One of the amines, or replace it with a mixture of diethylenetriamine, ethylenediamine, triethylenetetramine, tetraethylenepentamine, and polyethylenepolyamine according to the same weight part, all of which can be qualified long-chain alkylpolyamine series Bitumen anti-stripping agent.

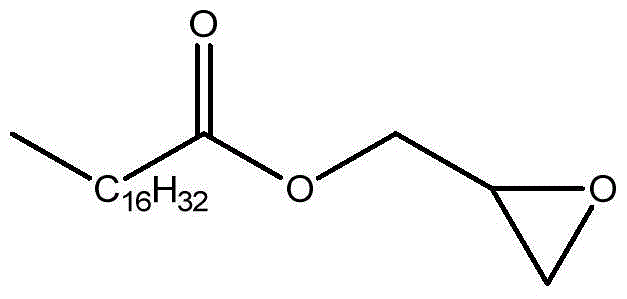

[0027] In this embodiment, the organic acid can be selected from butyric acid to tetracosacid and its homologues or mixtures, preferably cheap and easy-to-obtain raw materials such as oleic acid and st...

Embodiment 2

[0041] The long-chain alkyl polyamine series asphalt anti-stripping agent of this embodiment, the anti-stripping agent raw material includes the following components by weight: 0.42 parts of long-chain alkyl organic acid, 0.19 part of epichlorohydrin, and 0.05 part of organic amine.

[0042]In this embodiment, the organic amine is ethylenediamine; in this embodiment, the ethylenediamine is replaced by diethylenetriamine, triethylenetetramine, tetraethylenepentamine, polyethylenepolyamine One of them, or replace it with a mixture of ethylenediamine, diethylenetriamine, triethylenetetramine, tetraethylenepentamine, and polyethylenepolyamine in the same weight part, to obtain qualified long-chain alkylpolyamine series asphalt Anti-stripping agent.

[0043] In this embodiment, the organic acid can be selected from butyric acid to tetracosacid and its homologues or mixtures, preferably cheap and easy-to-obtain raw materials such as oleic acid and stearic acid; the polyamine can be ...

Embodiment 3

[0049] For the long-chain alkyl polyamine series asphalt anti-stripping agent of this embodiment, the anti-stripping agent raw materials include the following components by weight: 0.76 parts of long-chain alkyl organic acid, 0.44 part of epichlorohydrin, and 0.14 part of organic amine.

[0050] In this embodiment, the organic amine is tetraethylenepentamine; in this embodiment, the tetraethylenepentamine is replaced by diethylenetriamine, triethylenetetramine, ethylenediamine, polyethylenepolyethylene One of the amines, or replace it with a mixture of tetraethylenepentamine, diethylenetriamine, triethylenetetramine, ethylenediamine, and polyethylenepolyamine in the same weight part, all of which can be qualified long-chain alkylpolyamine series Bitumen anti-stripping agent.

[0051] In this embodiment, the organic acid can be selected from butyric acid to tetracosacid and its homologues or mixtures, preferably cheap and easy-to-obtain raw materials such as oleic acid and stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com