Pickling apparatus, pickling method, and quartz sand preparation method

A technology of pickling device and quartz sand, applied in the directions of silicon dioxide and silicon oxide, can solve the problems of complicated pickling process, troublesome preparation, unfavorable cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

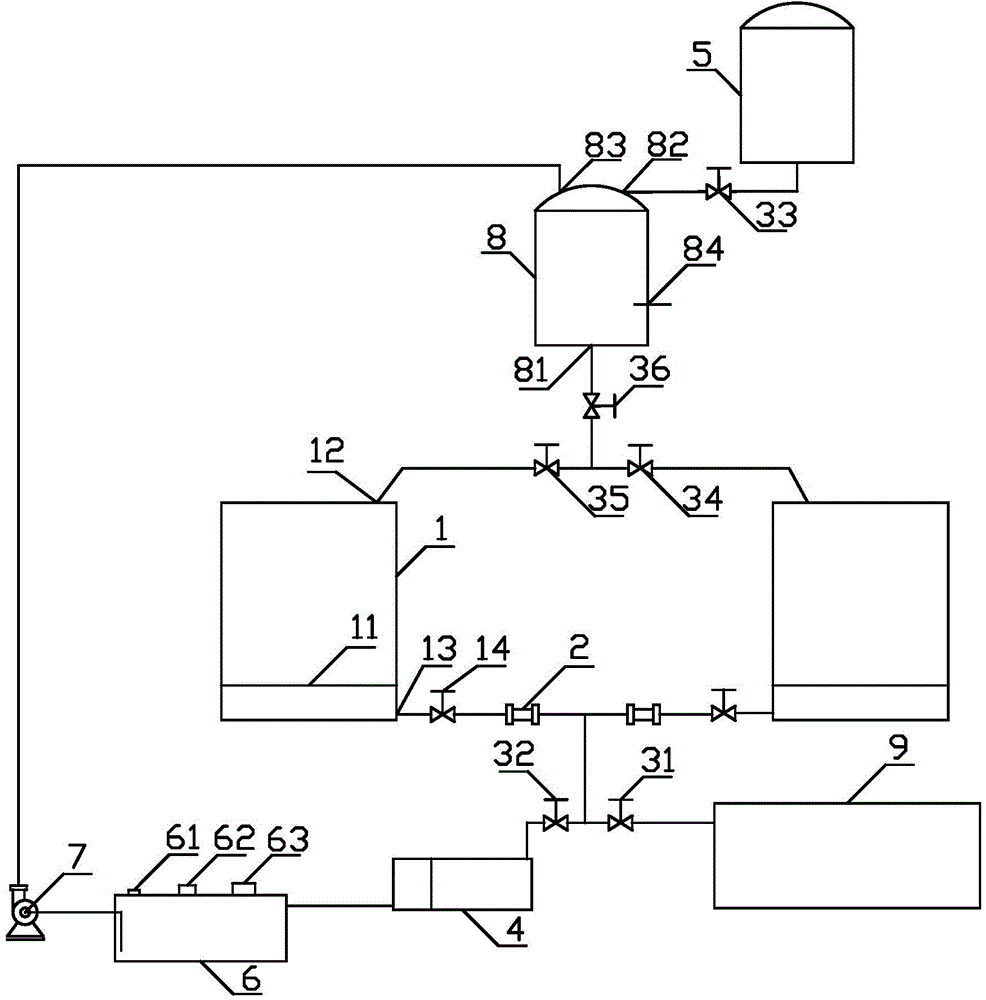

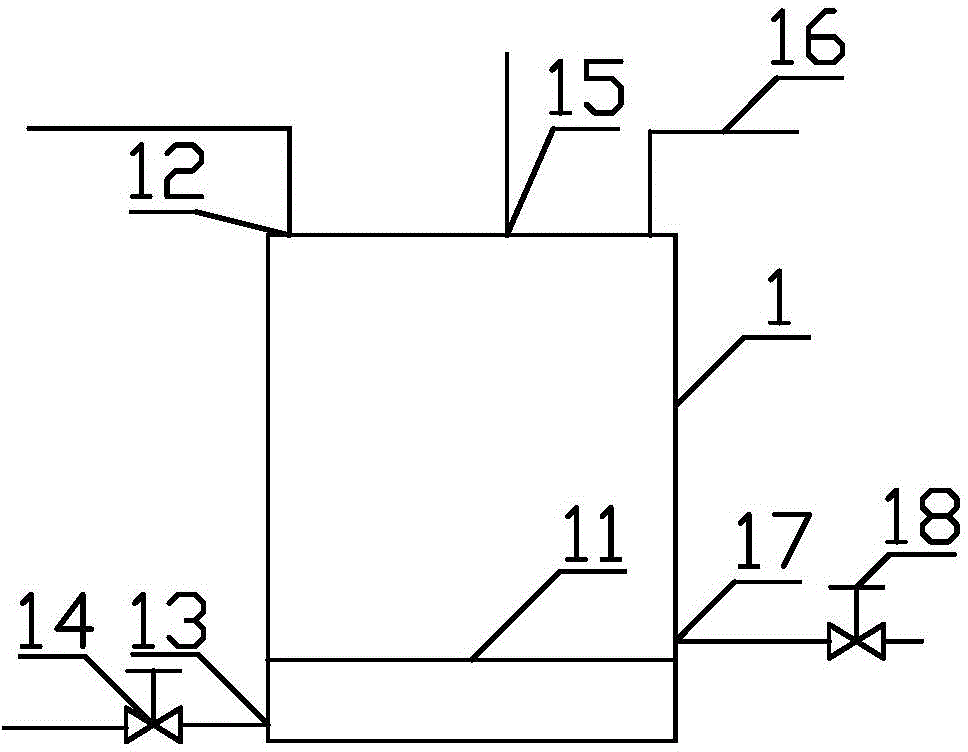

[0034] see Figure 1-4 , the embodiment of the present invention provides a pickling device, including the original acid bucket 5, the acid bucket 8, the wastewater treatment structure 9 and at least one pickling bucket 1, the original acid bucket 5, the acid bucket 8, the pickling bucket 1 It is connected with the waste water treatment structure 9 in turn. Wherein, the original acid bucket 5, the acid bucket 8, the pickling bucket 1 and the waste water treatment structure 9 are basically the same as the corresponding structure of the existing pickling device, the difference is that the pickling device provided by the present invention has also increased The acid recovery part, the acid recovery part includes a selective conveying structure, an acid recovery structure and at least one visualizer 2 , that is, the pickling device in the present invention also includes a selective conveying structure, an acid recovery structure and at least one visualizer 2 . Among them, the pic...

Embodiment 2

[0056] see figure 1 and 5 , the embodiment of the present invention provides the pickling method using the pickling device provided in Example 1, the method comprising the following steps:

[0057] (1) Acid soaking: soak the quartz sand with a moisture content of less than 5% in the pickling bucket for 5-10 days with the hydrochloric acid output from the acid bucket. The mass ratio of quartz sand to hydrochloric acid is 1:0.4-0.6.

[0058] Specifically, fill 60-75% of the volume of the pickling bucket 1 with quartz sand, flatten its upper part after installation, and then add hydrochloric acid from the acid bucket 8 to the pickling bucket 1 through the pipeline, and the hydrochloric acid is basically full of acid. After washing the barrel 1, add a film to seal the top of the pickling barrel 1 and soak for 5-10 days.

[0059] In another solution of the embodiment of the present invention, it is possible to directly use recovered hydrochloric acid with a MW greater than 16 for...

Embodiment 3

[0072] see Figure 6 , the embodiment of the present invention provides a quartz sand preparation process, the quartz sand preparation process includes the following steps:

[0073] 201 Machine sorting: Use a sorting machine to select ore with less impurities and high quality.

[0074] 202 Crushing: Crushing the ore into particles with a particle size of less than 5cm using a crusher.

[0075] 203 Washing: Use a material selector and water to wash the quartz sand particles.

[0076] 204 sieving: small particles of quartz sand (particle size less than 5cm) are allowed to pass through, and large particles of quartz sand can be returned to 202 for further crushing.

[0077] 205 candidates: manual selection to remove impurities in the quartz sand.

[0078] 206 Grinding: Use an iron mill to grind the quartz sand particles into 40-200 mesh quartz sand powder.

[0079] 207 Water magnetic separation: magnetically separate quartz sand powder in flowing water through a magnetic sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com