Amino-functional ordered mesoporous carbon material and preparation method and application thereof

A technology of amino-functionalization and mesoporous carbon, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. It can solve problems such as complex process, strong irritation, and unfavorable mass production. Achieve the effects of simple operation, increased concentration and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

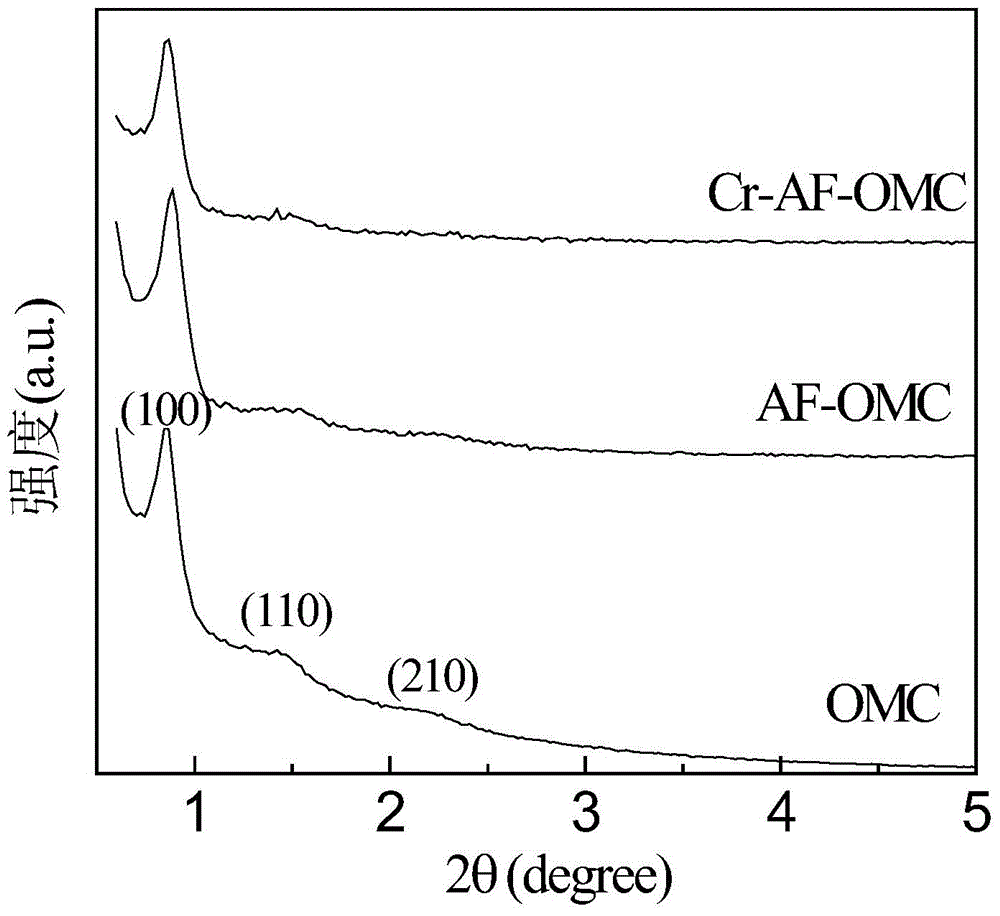

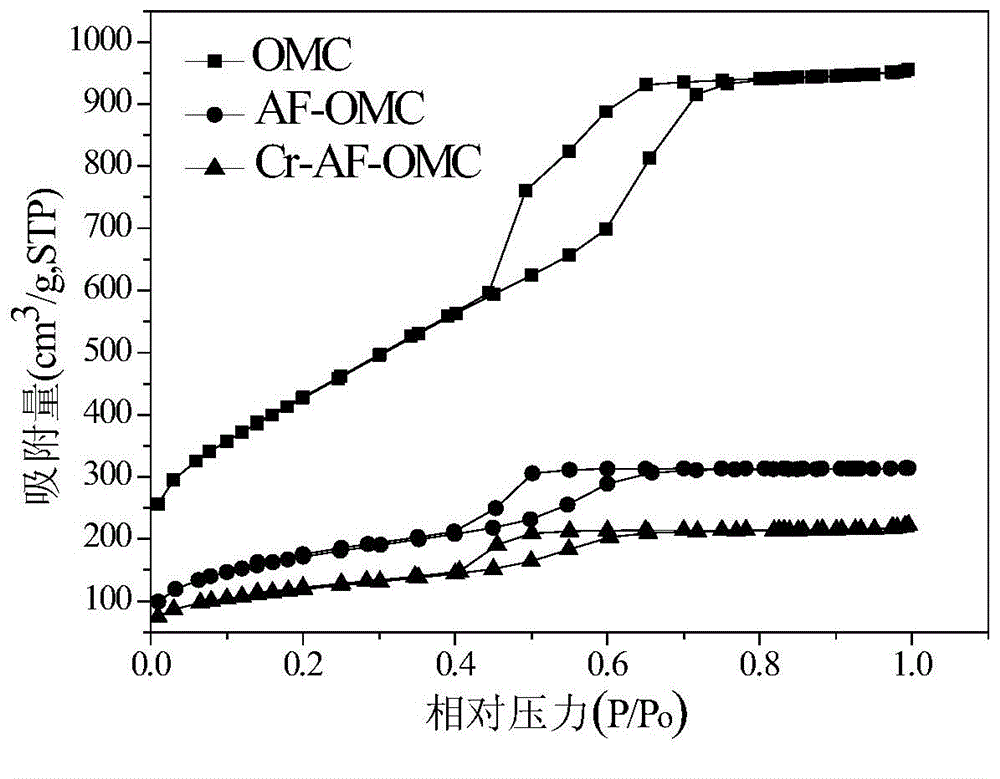

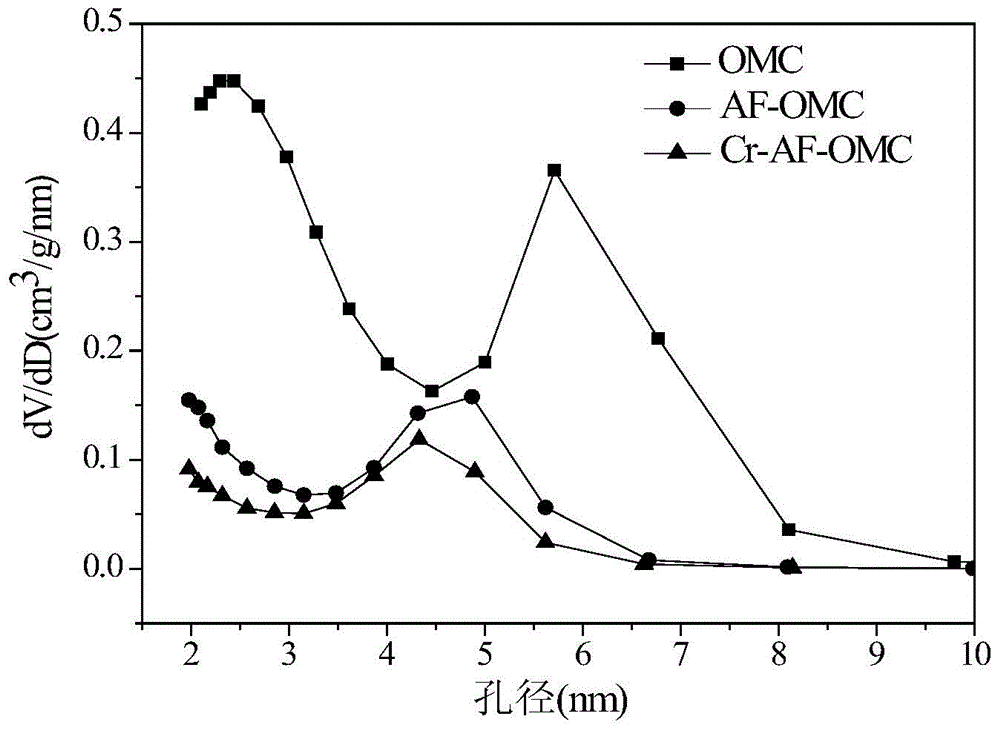

Embodiment 1

[0029] Step 1: Melt 6.1g of phenol at 40-45°C. After the phenol is completely melted, slowly add 1.3g of 20wt% sodium hydroxide solution, stir evenly, add 9.68g of 37wt% formaldehyde solution, and put the mixed system in a water bath at 75°C. After stirring and reacting for 1 h, it was cooled to room temperature, and the pH was adjusted to neutral with dilute hydrochloric acid solution. Then it was dried under vacuum overnight to obtain phenolic prepolymer (PF), and then the PF prepolymer was dissolved in ethanol solution to form a phenolic ethanol solution with a mass fraction of 20%. Weigh 1g of F127 and dissolve it in 10g of absolute ethanol, add 1g of 0.2mol / L hydrochloric acid solution, and stir at 40°C to obtain a clear solution. Then gradually add 2.08g of tetraethyl orthosilicate and 5g of 20wt% phenolic resin ethanol solution dropwise, and stir magnetically for 2 hours to obtain a transparent and homogeneous solution. Then it was transferred to an evaporating dish, v...

Embodiment 2

[0032] The first step: with embodiment 1.

[0033] Step 2: put ordered mesoporous carbon into 2mol / L nitric acid solution for oxidation, the molar ratio of ordered mesoporous carbon to nitric acid is 1:14, stir at 50-60°C for 2 hours, filter the product, Wash and dry in a vacuum oven at 45-55°C. Disperse the dried product in anhydrous toluene, add organosilane coupling agent (3-aminopropyl) trimethoxysilane (APTS), the molar ratio of APTS to ordered mesoporous carbon is 1, and the Reflux at °C for 24 hours, filter the product with suction, wash, and dry in a vacuum oven at 45-55°C. The dried product was protonated with 0.2 mol / L hydrochloric acid solution, stirred at room temperature for 6 hours, filtered, and dried in a vacuum oven at 45-55°C to obtain amino-functionalized ordered mesoporous carbon.

Embodiment 3

[0035] The first step: with embodiment 1.

[0036] Step 2: put ordered mesoporous carbon into 6mol / L nitric acid solution for oxidation, the molar ratio of ordered mesoporous carbon to nitric acid is 1:14, stir at 50-60°C for 2 hours, filter the product, Wash and dry in a vacuum oven at 45-55°C. Disperse the dried product in anhydrous toluene, add organosilane coupling agent (3-aminopropyl) trimethoxysilane (APTS), the molar ratio of APTS to ordered mesoporous carbon is 1, and the Reflux at °C for 24 hours, filter the product with suction, wash, and dry in a vacuum oven at 45-55°C. The dried product was protonated with 0.2 mol / L hydrochloric acid solution, stirred at room temperature for 6 hours, filtered, and dried in a vacuum oven at 45-55°C to obtain amino-functionalized ordered mesoporous carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com