Condensing gas water heater

A gas-fired water heater and condensing technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of limited heat exchange effect of plate-type air preheaters, insufficient utilization of waste heat of flue gas, The problem of poor separation effect of the steam-water separator can reduce the escape loss of hot water, improve the heat exchange efficiency of flue gas, and improve the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

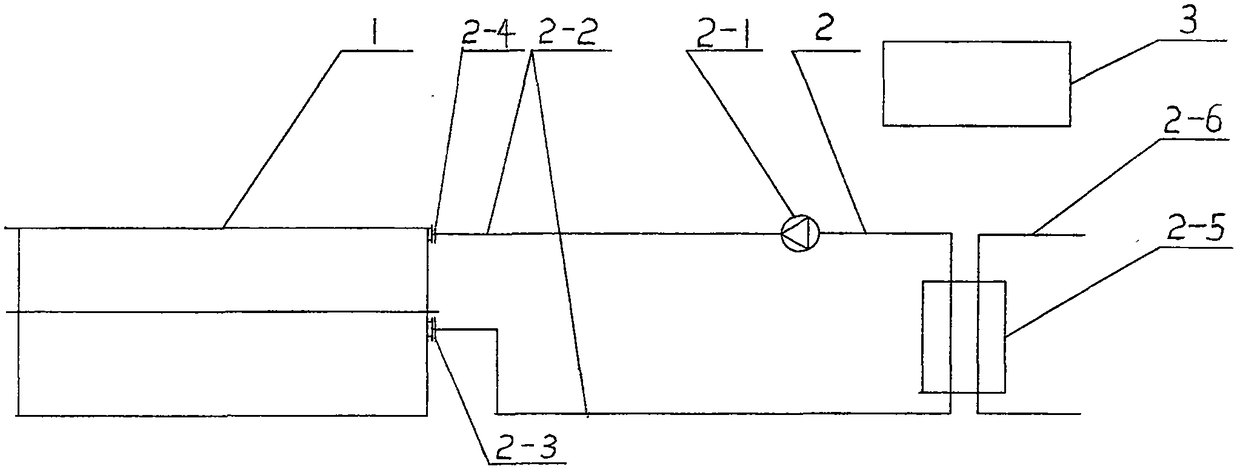

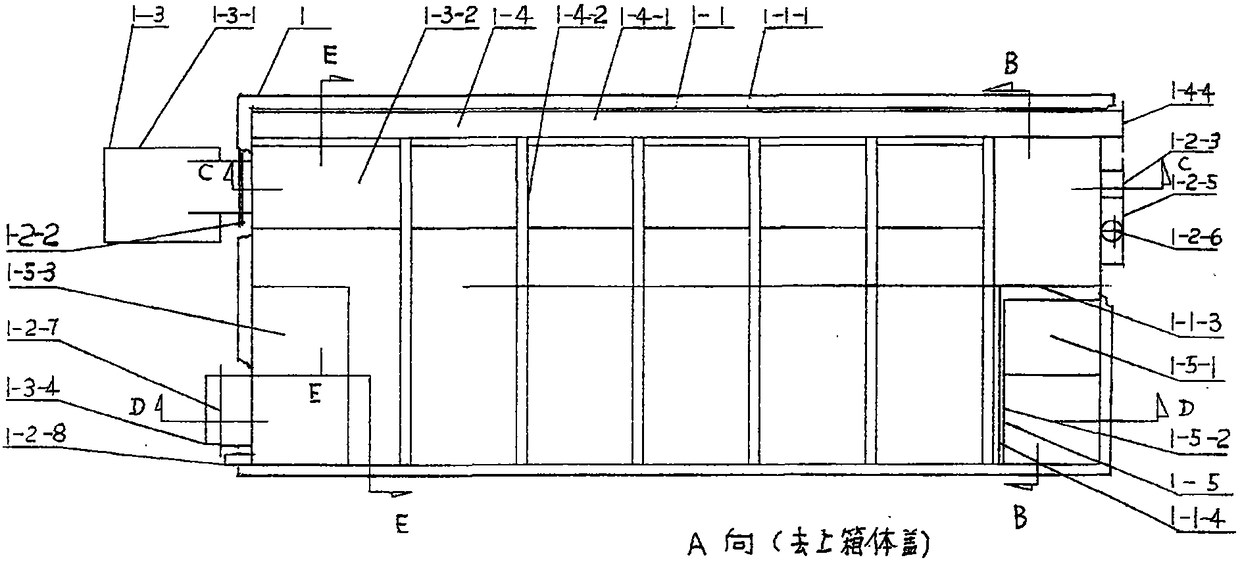

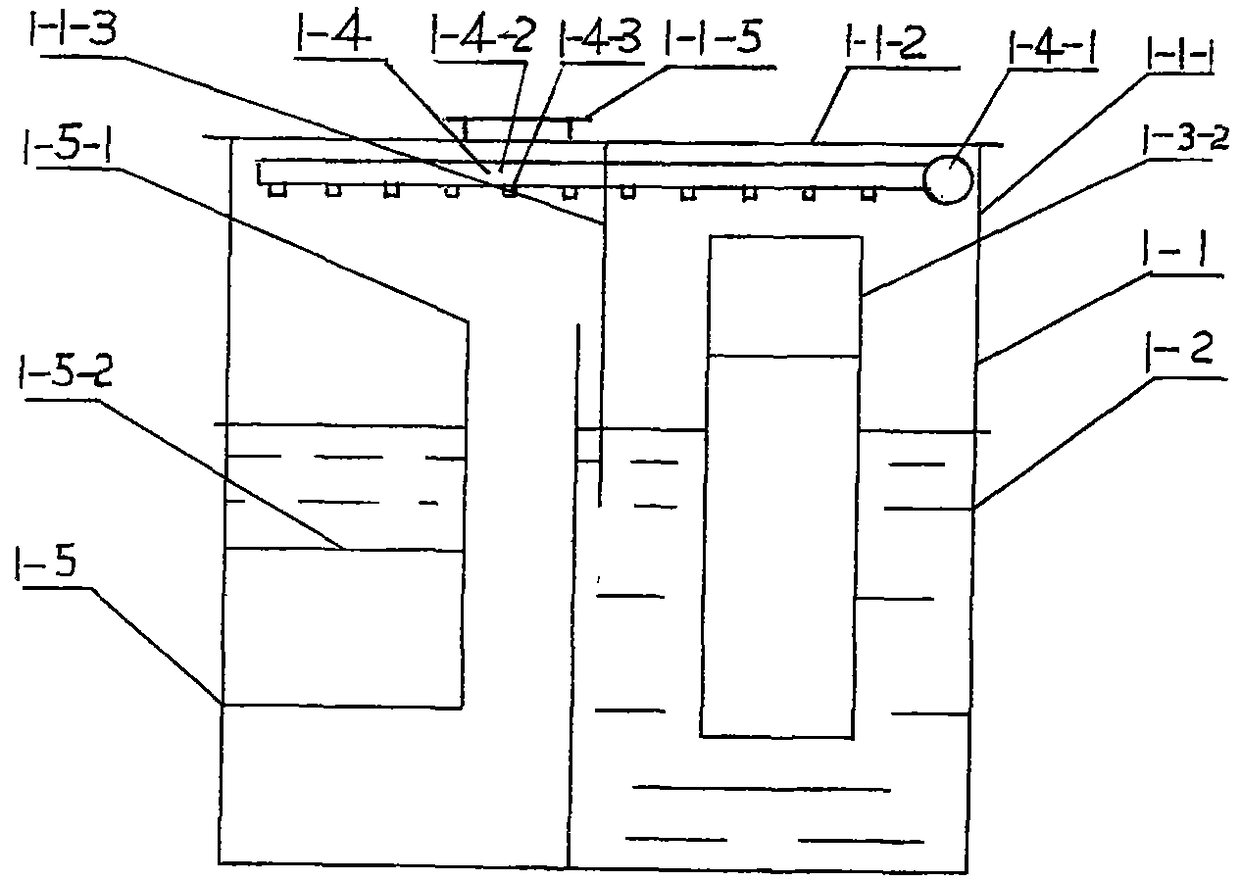

[0021] Depend on figure 1 It can be seen that the condensing gas water heater includes a condensing gas water heater body 1 , a hot water internal circulation heat exchange system 2 and an electric control cabinet 3 . The body 1 of the condensing gas water heater passes through the water outlet flange 1-2-3 of the lower box, the water inlet flange 1-4-4 of the spray water inlet main pipe, and the water inlet flange 2-3 of the hot water internal circulation pipe. The water outlet flange 2-4 of the hot water internal circulation pipeline is connected with the hot water internal circulation heat exchange system 2. The electric control cabinet 3 communicates with the burner 1-3-1 in the condensing gas water heater body 1, the hot water internal circulation pump 2-1 in the hot water internal circulation heat exchange system 2, various operating parameters, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com