Method for predicting components by analytical process to prepare Fe-Ga alloy film

A technology of alloy thin film and analysis method, which is applied in the direction of material selection for magnetostrictive devices, metal material coating process, manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problem of difficult preparation of low melting point gallium metal Alloy film and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Using JZCK-600F multi-functional coating equipment, using alloy single target for magnetron sputtering. Alloy target composition is Fe 75 Ga 25 . A circular alloy target with a diameter of 60 mm and a thickness of 3 mm is installed on the target holder, and the target base distance is 100 mm.

[0075] Coating sputtering process parameters and operation steps are:

[0076] 1. Selection and pretreatment of substrates

[0077] Choose polished glass or Si wafer as the substrate. Before sputtering, the surface of the substrate is strictly cleaned with acetone, ethanol, and deionized water to remove oil, dirt, and oxides. Ultrasonic cleaning is used to enhance the cleaning effect. After cleaning, dry it with a heat source for later use;

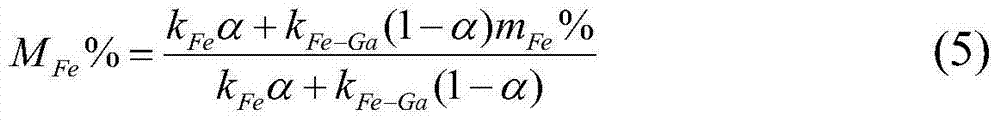

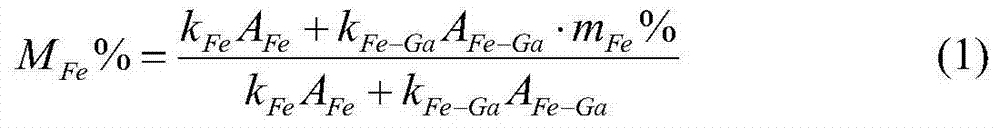

[0078] 2. Prediction and calculation of film composition

[0079] A certain number of iron sheets are selected, and the pure iron sheets are attracted and attached to the etching area of the alloy target by magnetic force, and the pu...

Embodiment 2

[0095] Using JZCK-600F multi-functional coating equipment, using alloy single target for magnetron sputtering. Alloy target composition is Fe 75 Ga 25 . A circular alloy target with a diameter of 60 mm and a thickness of 3 mm is installed on the target holder, and the target base distance is 100 mm.

[0096] Coating sputtering process parameters and operation steps are:

[0097] 1. Selection and pretreatment of substrates

[0098]Choose polished glass or Si wafer as the substrate. Before sputtering, the surface of the substrate is strictly cleaned with acetone, ethanol, and deionized water to remove oil, dirt, and oxides. Ultrasonic cleaning is used to enhance the cleaning effect. After cleaning, dry it with a heat source for later use;

[0099] 2. Prediction and calculation of film composition

[0100] A certain number of iron sheets are selected, and the pure iron sheets are attracted and attached to the etching area of the alloy target by magnetic force, and the pur...

Embodiment 3

[0116] Using JZCK-600F multi-functional coating equipment, using alloy single target for magnetron sputtering. Alloy target composition is Fe 75 Ga 25 . A circular alloy target with a diameter of 60 mm and a thickness of 3 mm is installed on the target holder, and the target base distance is 100 mm.

[0117] Coating sputtering process parameters and operation steps are:

[0118] 1. Selection and pretreatment of substrates

[0119] Choose polished glass or Si wafer as the substrate. Before sputtering, the surface of the substrate is strictly cleaned with acetone, ethanol, and deionized water to remove oil, dirt, and oxides. Ultrasonic cleaning is used to enhance the cleaning effect. After cleaning, dry it with a heat source for later use;

[0120] 2. Prediction and calculation of film composition

[0121] A certain number of iron sheets are selected, and the pure iron sheets are attracted and attached to the etching area of the alloy target by magnetic force, and the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com