Steel for chemical equipment fastener and production method thereof

A technology of chemical equipment and production method, which is applied to the steel for fasteners, the steel for chemical equipment fasteners and their production fields, to achieve the effects of improving the purity, ensuring the uniformity of the organization and the reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

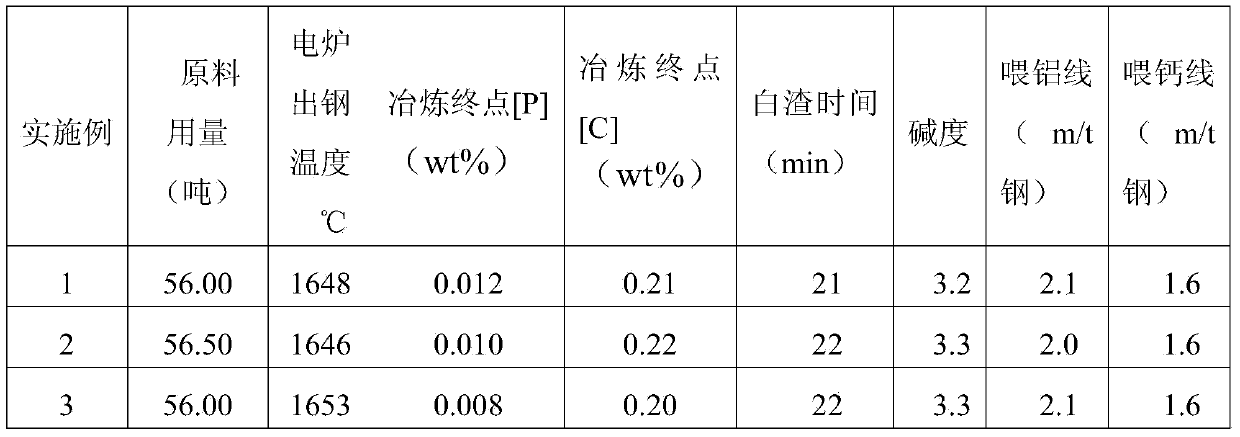

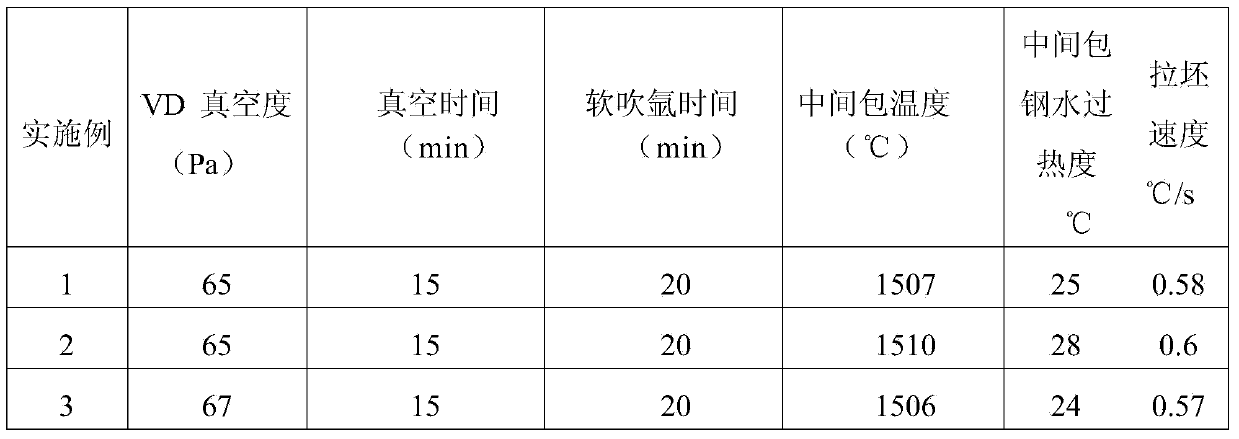

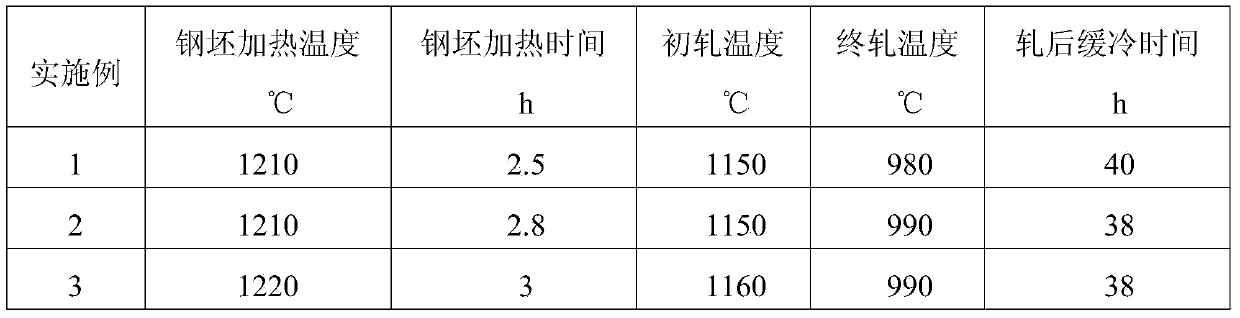

[0032] A method for preparing steel for fasteners on American Standard chemical equipment comprises the following steps:

[0033] (1) Electric furnace smelting

[0034] Electric furnace smelting is used. In order to effectively reduce the content of inclusions in steel, the amount of molten iron added in electric furnace smelting should be increased to more than 60%. The raw materials entering the furnace should be optimized, and high-phosphorus and high-sulfur scrap steel such as slag iron and can side iron are not allowed. . The whole process of electric furnace smelting maintains foam slag operation, ensures good oxidation boiling, promotes the removal of gases and inclusions, and ensures the oxidation, high alkalinity and fluidity of electric furnace slag for rapid dephosphorization, in order to ensure that the finished steel [P]≤ 0.015wt%, control electric furnace end point [P] ≤ 0.012wt%. High-temperature rapid decarburization, because the carbon content in the finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com