Propofol water-soluble naphthenic phosphate ester derivative

A technology of propofol and bisphosphonic acid, applied in the field of medicinal chemistry, to avoid injection pain and embolism, increase solubility, and reduce side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of propofol-1-chlorocyclopropyl ether

[0024]

[0025] Under nitrogen protection, sodium hydride (2.5 g, dispersed in mineral oil, 60% by mass, 61.6 mmol) was suspended in anhydrous tetrahydrofuran (100 mL) while stirring, and propofol was added in batches at 0 °C (10.0 g, 56.0 mmol), the resulting mixture was stirred for 10 minutes, and a solution of 1-chloro-1-iodocyclopropane (12.5 g, 61.6 mmol) in tetrahydrofuran (10 mL) was added dropwise. After the dropwise addition was completed, stirring was continued at room temperature for 6 hours. Filter, evaporate solvent under reduced pressure, residue recrystallizes with the mixed solvent of sherwood oil and ethyl acetate (V 石油醚 :V 乙酸乙酯 =6:1), dried to obtain 12.6 g of white solid, yield 89.1%, HPLC purity: 99.4% (254 nm). 1 H NMR (400 MHz, CDCl 3 ( m, 2H).

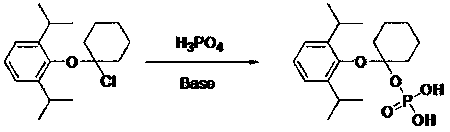

Embodiment 2

[0026] Embodiment 2: Preparation of O-[1-(propofol-O base)]cycloprop-1-yl monoester phosphoric acid

[0027]

[0028] A mixture of propofol-1-chlorocyclopropyl ether (12.0 g, 47.5 mmol), phosphoric acid (5.6 g, 57.0 mmol), triethylamine (5.8 g, 57.0 mmol), ethanol (100 mL) was heated to 70 °C for 3 hours. Concentrate the solvent under reduced pressure (-0.09 MPa, 40 °C) until white crystals precipitate, then cool with ice-water mixture, filter, and dry to obtain 9.3 g of white solid, yield 62.0%, HPLC purity: 97.6% (254 nm) . 1 H NMR (400MHz, DMSO-d 6 ( m, 2H).

Embodiment 3

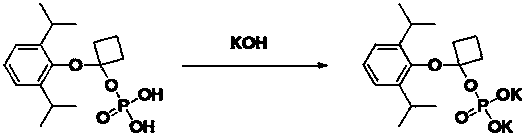

[0029] Example 3: Preparation of O-[1-(propofol-O base)]cycloprop-1-yl monoester phosphate disodium

[0030]

[0031] Dissolve O-[1-(propofol-O-yl)]cycloprop-1-yl monoester phosphoric acid (4.5 g, 14.3 mmol) in water (30 mL), add sodium hydroxide (1.15 g, 28.6 mmol). Stirring was continued at room temperature for 1 hour, water was evaporated under reduced pressure, and dried to obtain 5.1 g of white solid, yield 100.0%, HPLC purity: 98.3% (254 nm). 1 H NMR (400MHz, D 2 O) δ: 7.35-7.19 (m, 2H), 6.93-6.62 (m, 1H), 3.20-3.12 (m, 2H), 1.25 (d, 12H), 0.84-0.79 (m, 2H), 0.72-0.66 (m, 2H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com