Method and system for processing fragile material

A brittle material and processing system technology, applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems that affect the processing accuracy, difficult to control the quality, and increase the processing time, so as to achieve a smooth fracture surface and save energy. The effect of high processing time and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

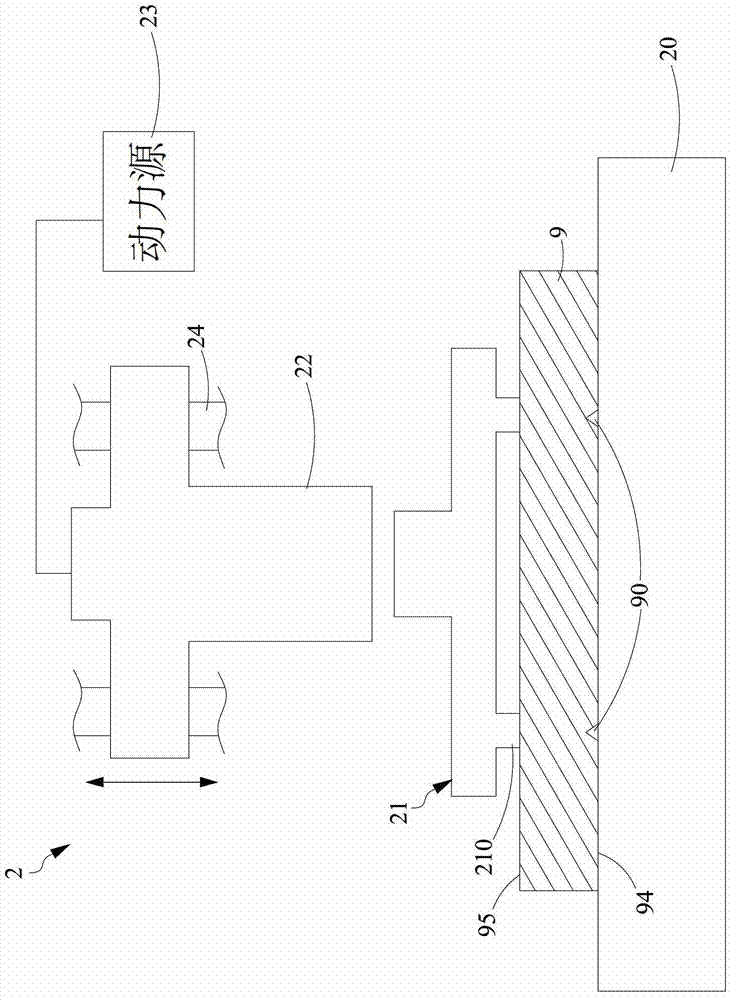

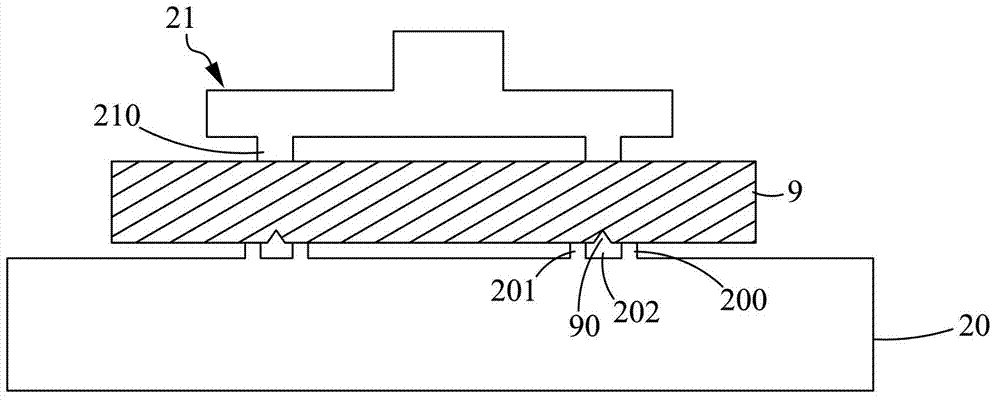

[0041] see Figure 1A As shown, this figure is a schematic diagram of an embodiment of the brittle material processing system of the present invention. The brittle processing system 2 includes a platform 20 , a jig 21 , an impact tool 22 and a power source 23 . The platform 20 supports a substrate 9 made of a brittle material, and a fracture profile 90 is formed on the surface or inside of the substrate 9 . The brittle material can be selected as glass, ceramics, crystalline material, etc., but not limited thereto. The crystalline material can be gemstone or silicon substrate. In addition, it should be noted that the surface of the substrate can have a reinforced structure layer, such as: metal coating or directly form a reinforced structure layer by material treatment of a specific thickness on the surface of the substrate to achieve wear resistance and scratch resistance. And not easy to break and other effects. The strengthening structure layer can be formed on a single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com