Method for increasing flaw detection yield of continuous casting sheet head billet and tail billet

A technology of pass rate and tail billet, which is applied in the field of continuous casting slab flaw detection, improves the field of continuous casting slab head and tail billet flaw detection pass rate, and achieves the effect of preventing slag coiling, improving internal quality and improving flaw detection pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

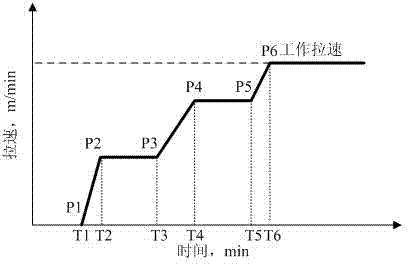

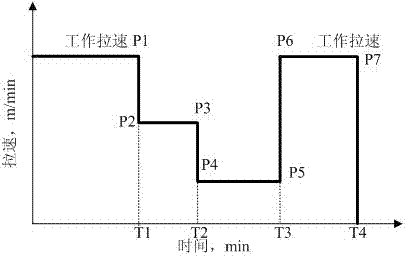

[0027] A method for improving the pass rate of flaw detection of the head and tail slabs of continuous casting slabs. The method improves the pass rate of flaw detection of the head and tail slabs by improving the internal quality of the slab during the casting process and the end of the pouring process, optimizing the process operation, and improving the pass rate of the head and tail slabs. Requirements are as follows:

[0028] (1) Continuous casting pouring operation

[0029] Before continuous casting starts, argon gas is blown into the tundish to remove the internal air to prevent secondary oxidation of the molten steel. The gas removal time is equal to the volume of the tundish / argon flow; At 2 o'clock, open the stopper, and the molten steel enters the mold from the tundish; when the molten steel level in the mold reaches the position of the side hole of the nozzle, add continuous casting casting slag to prevent secondary oxidation of the molten steel on the inner surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com