Preparation method of lithium ion battery cathode material composited by in-situ synthesis Fe-Fe3O4

A lithium-ion battery, fe-fe3o4 technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as low conductivity, achieve high specific capacity, wide source of raw materials, and increased transmission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

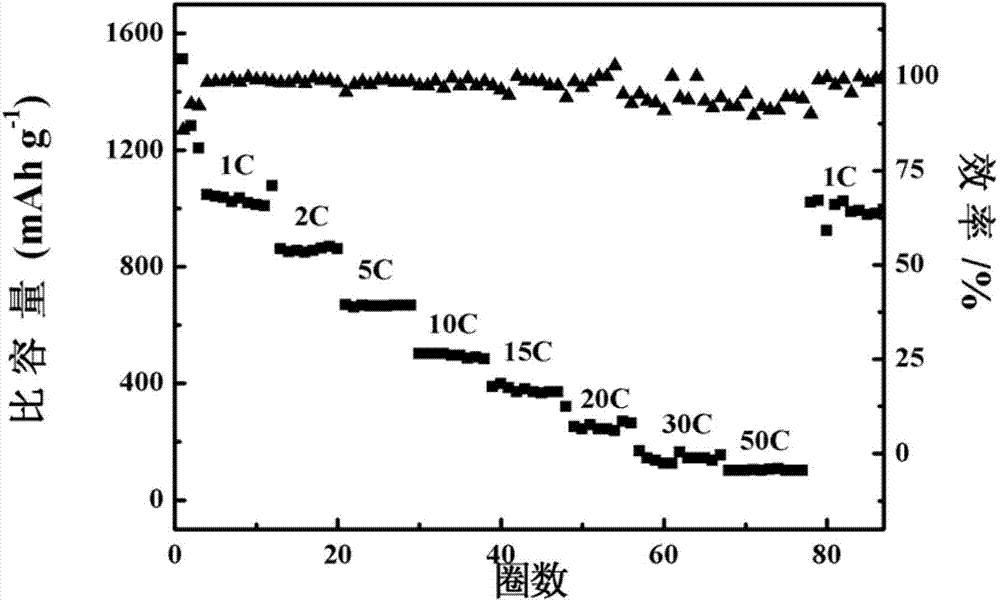

Embodiment 1

[0016] The CTiC nanowire array was used as the matrix in 0.25mol L -1 FeSO 4 +70mL L -1 Triethanolamine deposition solution, constant current -0.010A cm -2 , deposited for 10 min to obtain a metal Fe film. Containing 0.3mol L -1 h 2 C 2 o 4 ,5%H 2 Soak in the mixed solution of O for 3h, and the soaking temperature is 45°C. Then put the prepared sample into the muffle furnace, calcined in the air for 2h, and the calcining temperature is 400°C to obtain the final Fe-Fe 3 o 4 / CTiC electrode. Assembled into a button lithium-ion battery for rate performance test. The results show that the specific capacity is as high as 1080mAh g at 1C charge and discharge current -1 .

Embodiment 2

[0018] CTiO 2 Nanowire array as a matrix in 0.1mol L -1 FeSO 4 +35mL L -1 In the triethanolamine deposition solution, a constant voltage of -1V was deposited for 5 minutes to obtain a metal Fe film. Containing 0.3mol L -1 h 2 C 2 o 4 ,50%H 2 Soak in the mixed solution of O for 1.5h, and the soaking temperature is 25°C. Then put the prepared sample into the muffle furnace, calcined in the air for 3h, and the calcining temperature is 350°C to get the final Fe-Fe 3 o 4 / CTiO 2 electrode. Assembled into a button lithium-ion battery for rate performance test. The results show that the specific capacity can reach 780mAh g at 2C charge and discharge current -1 .

Embodiment 3

[0020] The CTiC nanowire array was used as the matrix in 0.5mol L -1 FeSO 4 +70mL L -1 In the triethanolamine deposition solution, a constant voltage of -0.2V was deposited for 15 minutes to obtain a metal Fe film. containing 0.5mol L -1 h 2 C 2 o 4 ,70%H 2 Soak in the mixed solution of O for 2h, and the soaking temperature is 35°C. Then put the prepared sample into the muffle furnace, calcined in the air for 2h, and the calcining temperature was 400°C to obtain the final Fe-Fe3 o 4 / CTiC electrode. Assembled into a button lithium-ion battery for rate performance test. The results show that the specific capacity is as high as 540mAh g at 5C charge and discharge current -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com