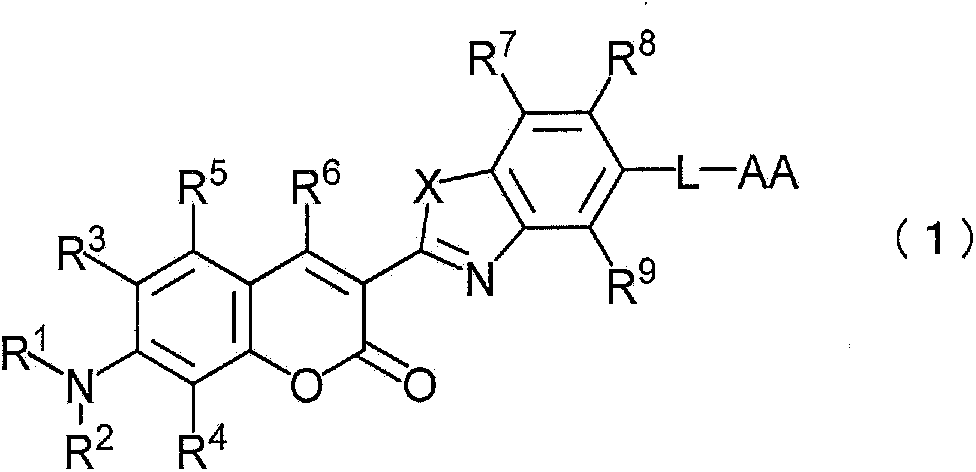

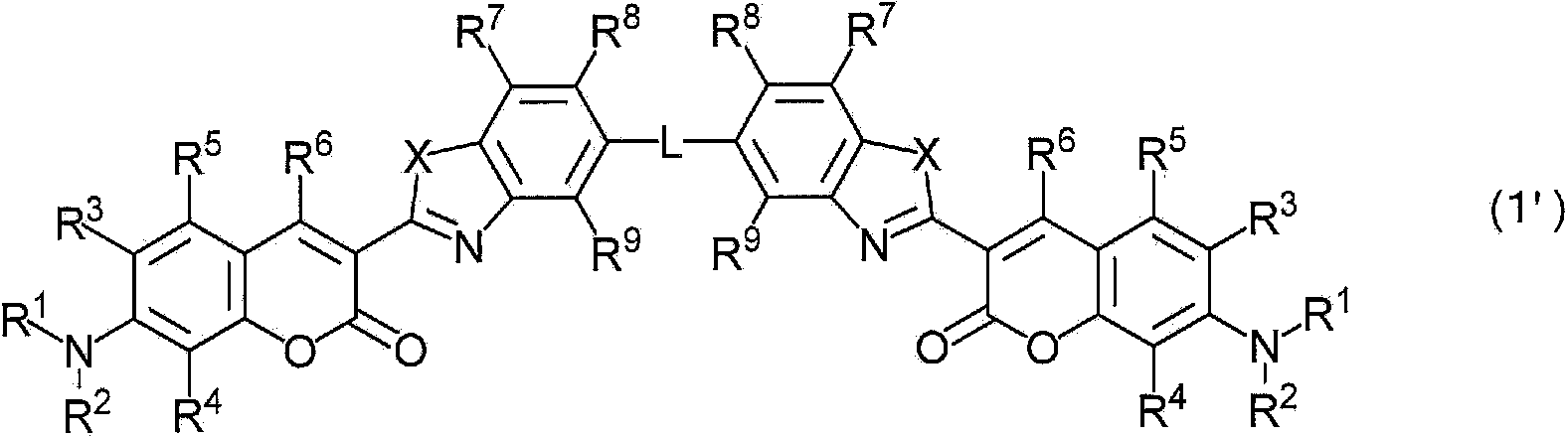

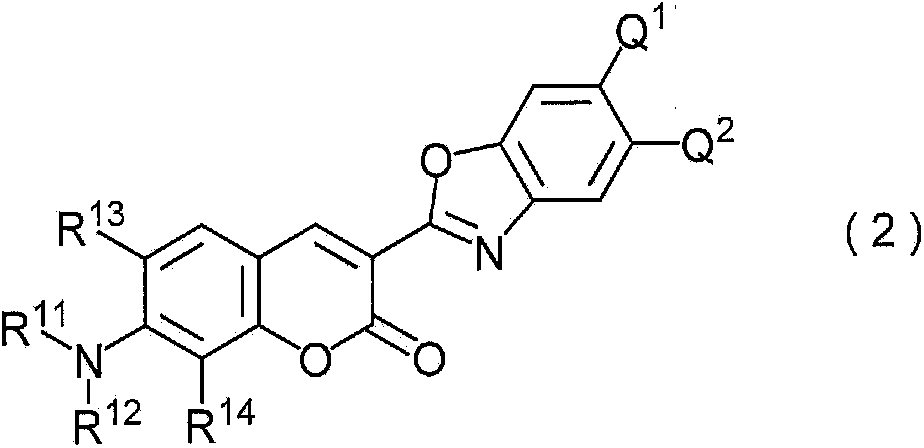

Colored curable resin composition

A technology of curable resin and composition, which can be used in nonlinear optics, instruments, photolithography process exposure devices, etc., and can solve the problems of color filters fully meeting the needs and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[1047] The following examples will illustrate the present invention in more detail. The "%" and "parts" in the examples refer to mass% and mass parts unless otherwise specified.

[1048] In the following synthesis examples, the structure of the compound was confirmed by NMR (JMM-ECA-500; manufactured by JEOL Ltd.) or mass spectrometry (LC: Agilent 1200 model, MASS: Agilent LC / MSDD6130 model).

[1049] The measurement of the weight average molecular weight (Mw) and the number average molecular weight (Mn) in terms of polystyrene of the resin was performed by the GPC method under the following conditions.

[1050] Device; HLC-8120GPC (manufactured by Tosei Co., Ltd.)

[1051] Chromatographic column; TSK-GELG2000HXL

[1052] Column temperature; 40℃

[1053] Solvent; THF

[1054] Flow rate; 1.0mL / min

[1055] The concentration of the solid content of the tested liquid; 0.001~0.01% by mass

[1056] Injection volume; 50μL

[1057] Detector; RI

[1058] Standard material for calibration; TSK STANDA...

Synthetic example 1

[1063] Bis(3-amino-4-hydroxyphenyl)sulfone (manufactured by Tokyo Chemical Industry Co., Ltd.) 10.6 parts, 4-(diethylamino) salicylaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.) 14.6 parts, benzene 3.17 parts of formic acid (manufactured by Tokyo Chemical Industry Co., Ltd.), 183 parts of 1-pentanol (manufactured by Tokyo Chemical Industry Co., Ltd.) and 8.61 parts of ethyl cyanoacetate (manufactured by Tokyo Chemical Industry Co., Ltd.) were mixed at 120°C Stir for 3 hours. To this reaction solution were added 14.6 parts of 4-(diethylamino) salicylaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), 3.17 parts of benzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd.), and ethyl cyanoacetate (Tokyo Chemical Industry Co., Ltd.) 8.61 parts of Chemical Industry Co., Ltd. product), and stirred at 120°C for 12 hours. After cooling the above reaction liquid to room temperature, the precipitated crystals were obtained as a residue of suction filtratio...

Synthetic example 2

[1068] 10.1 parts of mixed bis(3-amino-4-hydroxyphenyl)dimethylmethane (manufactured by Changzhou Sunshine Pharmaceutical Raw Materials Co., Ltd.), 4-(diethylamino) salicylaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.) 15.2 parts, benzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd.) 3.26 parts, 1-pentanol (manufactured by Tokyo Chemical Industry Co., Ltd.) 191 parts and ethyl cyanoacetate (manufactured by Tokyo Chemical Industry Co., Ltd.) 8.89 parts, Stir at 120°C for 3 hours. To this reaction solution were added 8.39 parts of 4-(diethylamino) salicylaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), 1.80 parts of benzoic acid (manufactured by Tokyo Chemical Industry Co., Ltd.), and 1-pentanol (manufactured by Tokyo Chemical Industry Co., Ltd.). 8.40 parts by Kogyo Co., Ltd. and 4.91 parts of ethyl cyanoacetate (manufactured by Tokyo Chemical Industry Co., Ltd.) were stirred at 120°C for 12 hours. After cooling the above reaction liquid to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com