Automatic compensation-type thermocouple metrological verification polarity extension connector

A technology of automatic compensation and metrology verification, applied in connection, measurement of heat, instruments, etc., can solve the problems of common compensation wire error, environmental temperature fluctuation, different thermoelectric properties of copper-nickel-plated alligator clips and thermocouples, etc., to improve work efficiency , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

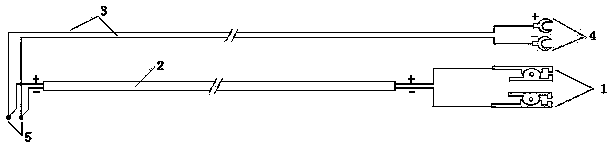

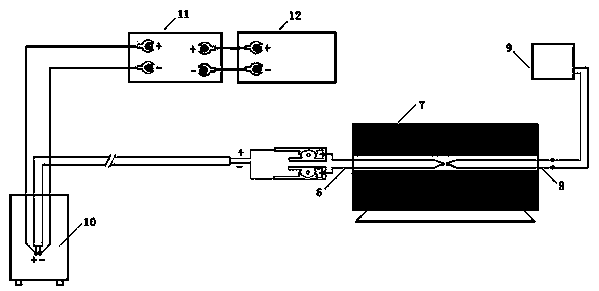

[0012] like Figure 1-2 As shown, an automatic compensating thermocouple measurement verification polarity extension connector, including alligator clip (1), compensation wire (2) and copper wire (3), one end of the compensation wire (2) passes through the positive and negative poles The lead wire is connected to the alligator clip (1), the other end of the compensation wire (2) is connected to the copper wire (3) through the positive and negative lead wires, and the other end of the copper wire (3) is connected to two copper terminal forks (4 ), the copper wire (3) has a free end (5) near the compensation wire (2), the free end (5) is located in the freezing point thermostat (10), and the temperature of the free end (5) is kept is 0 degree; the copper wiring fork (4) is used to connect to the low potential changeover switch (11) and the six-and-a-half digit multimeter (12) to form a measurement circuit; the alligator clip (1) is clamped on the industrial thermocouple to be ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com