Multi-layer belt type drying system

A drying system and multi-layer belt technology, applied in progressive dryer, drying gas arrangement, drying and other directions, can solve the problems of low material processing efficiency and large equipment space, and achieve simple structure, small footprint, Manipulate flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

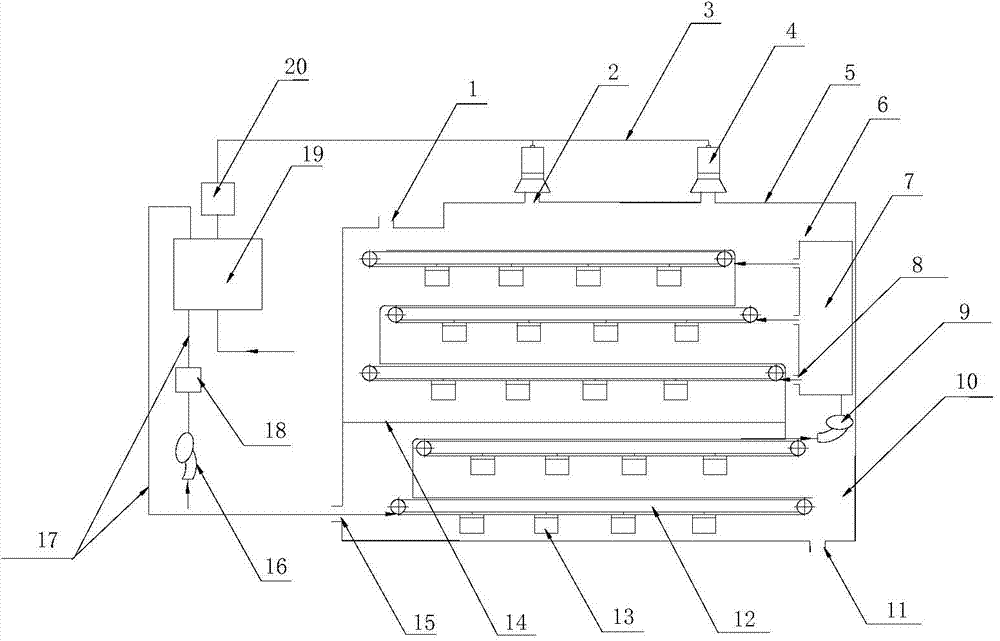

[0029] see figure 1 , a multi-layer belt drying system, including a drying box 5 with two air outlets 2 on the top and five layers of conveyor belts 12 made of perforated stainless steel sheets located in the drying box 5, the bottom conveyor belt The input end of the upper layer is connected to the output end of the adjacent conveying mesh belt. There are several circulating fans 13 under each layer of conveying mesh belt. The distribution density of the circulating fans 13 is every 2.5-4m 2 The area of the conveyor belt is set to one.

[0030] The multi-layer belt drying system also includes:

[0031] The air supply pipe 17 communicates with the air supply port 15 at the bottom of the cooling chamber for transporting air;

[0032] The exhaust pipe 3 communicates with the two exhaust outlets 2 on the top of the drying box, and each exhaust outlet is provided with a dehumidification fan 4, and the outlets of the two dehumidification fans are aggregated to the exhaust pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com