Method for preparing clean fuel from coal tar, method for preparing clean fuel from coal and prepared clean fuel

A clean fuel, coal tar technology, applied in the petroleum industry, processing hydrocarbon oil, preparation of liquid hydrocarbon mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

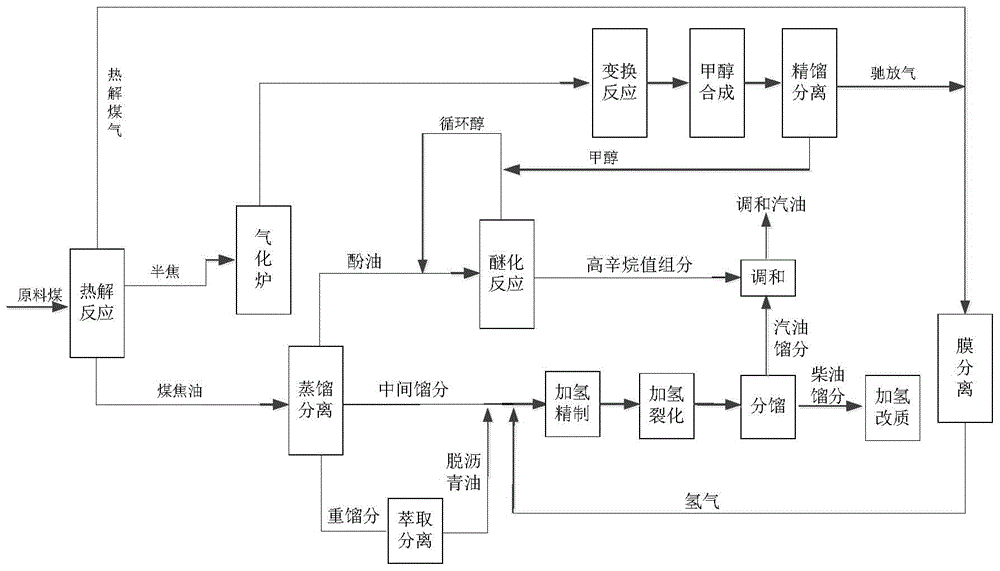

[0081] like figure 1 The process flow shown is as follows:

[0082] (1) The raw coal (Shenmu coal) is pulverized and sent to a vertical carbonization furnace for pyrolysis reaction at a pressure of 0.05MPa and a temperature of 650°C to obtain coal tar (see Table 1 below for properties), semi-coke and pyrolysis gas . The semi-coke is sent to the fluidized bed gas generator, under the conditions of pressure 0.13MPa, temperature 1000°C, gas-solid ratio 5:1 (volume / volume), with water vapor and oxygen (water vapor and oxygen The volume ratio is 4:1) to react to obtain gasified crude gas. The gasified crude gas is pressurized to 3.0MPa and then enters the sulfur-resistant conversion device, and the components in the gas meet the requirements of H in the raw material gas for methanol synthesis. 2 / CO requirements, the converted gas enters the desulfurization device to reduce the total sulfur content in the gas to less than 0.1ppm, and then pressurizes to 5.0MPa through the compre...

Embodiment 2

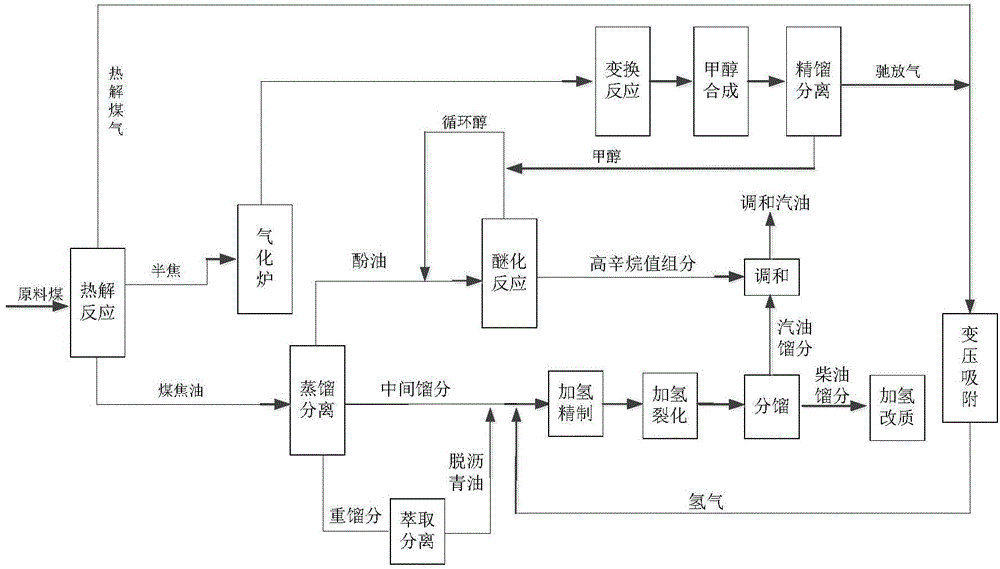

[0096] like figure 2 The process flow shown is as follows:

[0097] (1) The raw coal (Shenmu coal) is pulverized and sent to a vertical carbonization furnace for pyrolysis reaction at a pressure of 0.05 MPa and a temperature of 650°C to obtain coal tar (see Table 1 above for properties), semi-coke and pyrolysis gas . The semi-coke is sent to the fluidized bed gas generator, under the conditions of pressure 0.13MPa, temperature 1000°C, gas-solid ratio 5:1 (volume / volume), with water vapor and oxygen (water vapor and oxygen The volume ratio is 4:1) to react to obtain gasified crude gas. The gasified crude gas is pressurized to 3.0MPa and then enters the sulfur-resistant conversion device, and the components in the gas meet the requirements of H in the raw material gas for methanol synthesis. 2 / CO requirements, the converted gas enters the desulfurization device to reduce the total sulfur content in the gas to less than 0.1ppm, and then pressurizes to 6.0MPa through the comp...

Embodiment 3

[0110] like figure 2The process flow shown is as follows:

[0111] (1) The raw coal (Tongliao coal) was pulverized and sent to a vertical carbonization furnace for pyrolysis reaction at a pressure of 0.03 MPa and a temperature of 550°C to obtain coal tar (see Table 6 for properties), semi-coke and pyrolysis gas. The semi-coke is sent into the gasifier, and the gasified crude gas is obtained under the conditions of a pressure of 2.8MPa and a temperature of 1200°C. The gasified crude gas is pressurized to 3.0MPa and then enters the sulfur-resistant conversion device, and the components in the gas meet the requirements of H in the raw material gas for methanol synthesis. 2 / CO requirements, the converted gas enters the desulfurization device to reduce the total sulfur content in the gas to less than 0.1ppm, and then pressurizes to 5.0MPaMPa through the compressor, and then enters the methanol synthesis device (fixed bed reactor) for methanol synthesis reaction. The conditions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com