Seaweed pyrolysis oil making system and method thereof

An oil system, pyrolysis technology, applied in the petroleum industry, direct heating dry distillation, preparation of liquid hydrocarbon mixtures, etc., to achieve the effects of avoiding heat loss, saving drying costs, and fast heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

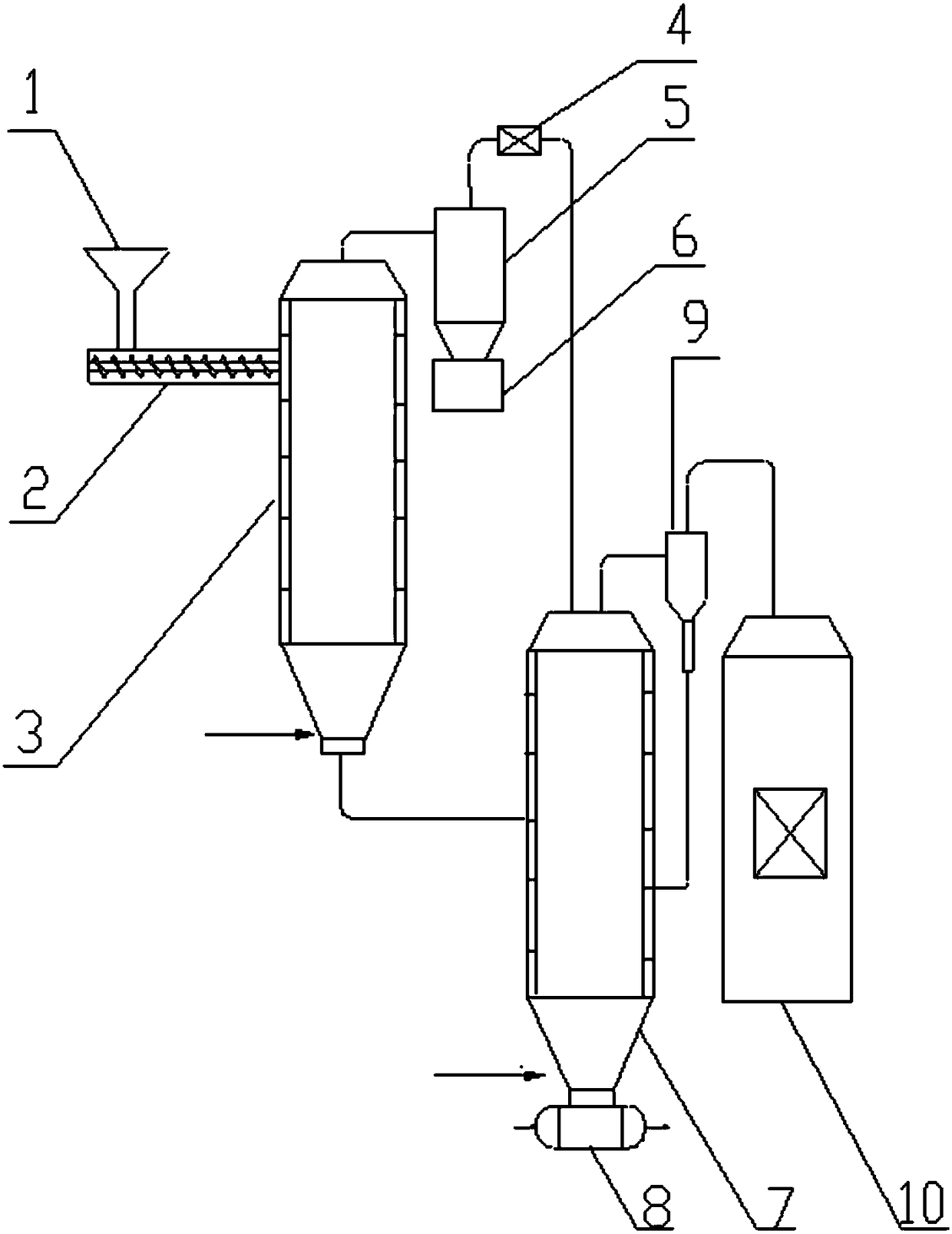

[0055] An oil production method according to the seaweed pyrolysis oil production system, comprising the following steps:

[0056] Step S1, sending the dried seaweed particles into the storage bin 1, and then into the pyrolysis device 3 via the feeding device 2;

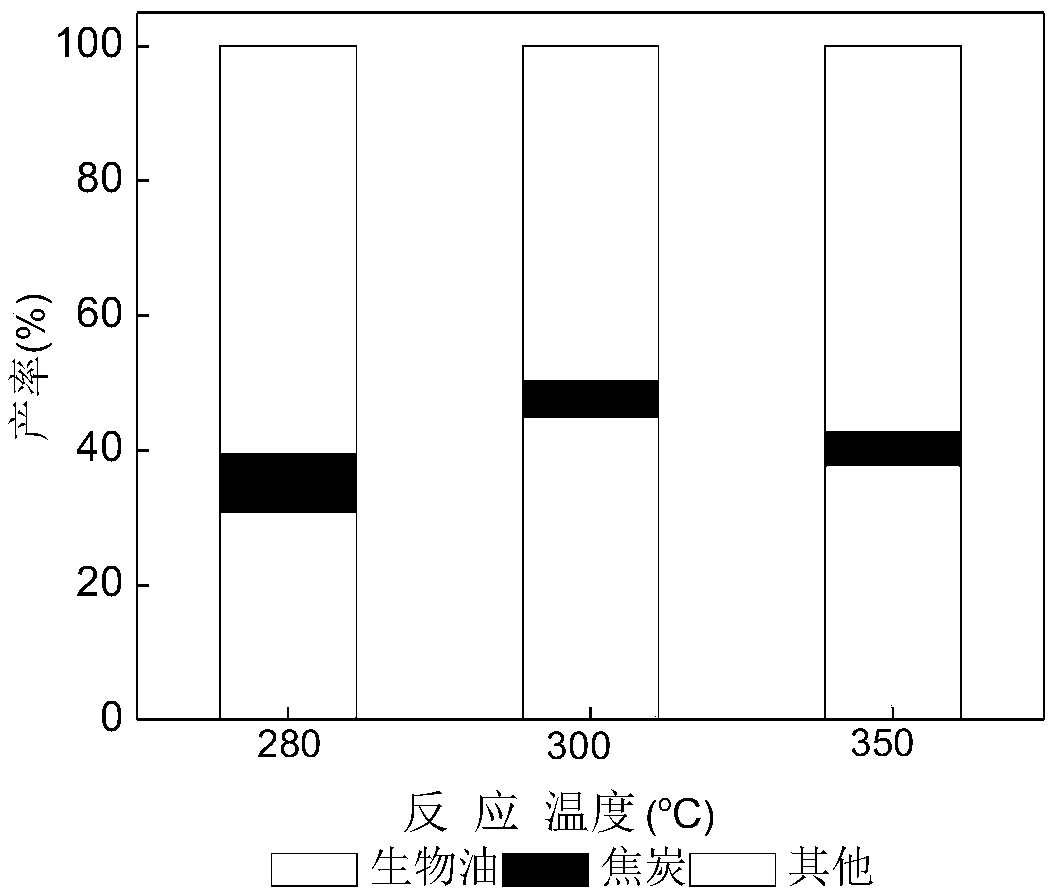

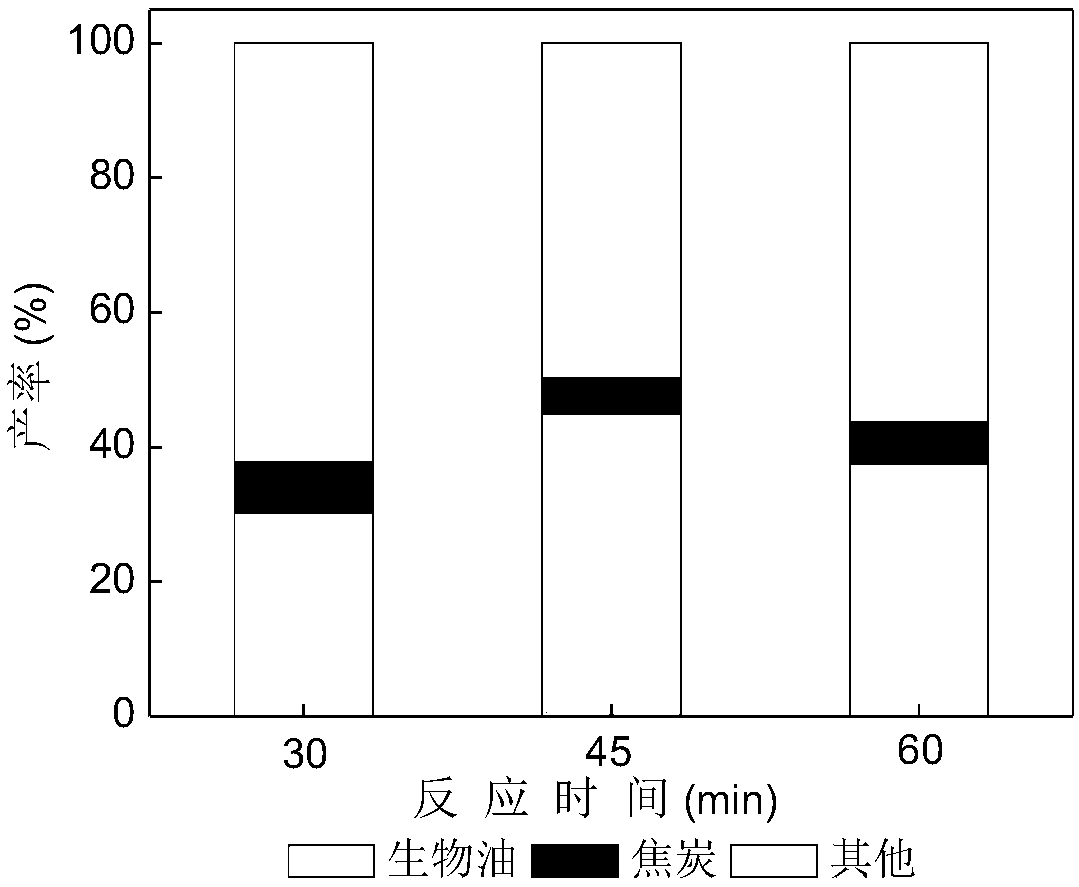

[0057] Step S2, seaweed particles are pyrolyzed in the pyrolysis device 3, using microwave heating method, the heating rate is fast, meeting the requirements of fast pyrolysis, and the pyrolysis reaction is carried out at a temperature of 500 ° C, under normal pressure, inert gas nitrogen atmosphere to produce crude bio-oil, semi-coke and non-condensable gas. After the crude bio-oil and non-condensable gas are separated by the oil-gas separator 5, the crude bio-oil is stored in the oil storage device 6. After the non-condensable gas passes through the gas purification device 4, the main Mainly carbon dioxide and water vapor are passed into the gasification device 7 as part of the gasification agent, and the semi-coke...

Embodiment 2

[0062] An oil production method according to the seaweed pyrolysis oil production system, comprising the following steps:

[0063] Step S1, sending the dried seaweed particles into the storage bin 1, and then into the pyrolysis device 3 via the feeding device 2;

[0064] Step S2, seaweed particles are subjected to pyrolysis reaction in the pyrolysis device 3, using microwave heating method, the heating rate is fast, which meets the requirements of rapid pyrolysis, and the pyrolysis reaction is carried out at a temperature of 525 ° C, under normal pressure, inert gas nitrogen atmosphere to produce crude bio-oil, semi-coke and non-condensable gas. After the crude bio-oil and non-condensable gas are separated by the oil-gas separator 5, the crude bio-oil is stored in the oil storage device 6. After the non-condensable gas passes through the gas purification device 4, the main Mainly carbon dioxide and water vapor are passed into the gasification device 7 as part of the gasificati...

Embodiment 3

[0069] An oil production method according to the seaweed pyrolysis oil production system, comprising the following steps:

[0070] Step S1, sending the dried seaweed particles into the storage bin 1, and then into the pyrolysis device 3 via the feeding device 2;

[0071] Step S2, seaweed particles are pyrolyzed in the pyrolysis device 3, using microwave heating method, the heating rate is fast, meeting the requirements of fast pyrolysis, and the pyrolysis reaction is carried out at a temperature of 550 ° C, under normal pressure, inert gas nitrogen atmosphere to produce crude bio-oil, semi-coke and non-condensable gas. After the crude bio-oil and non-condensable gas are separated by the oil-gas separator 5, the crude bio-oil is stored in the oil storage device 6. After the non-condensable gas passes through the gas purification device 4, the main Mainly carbon dioxide and water vapor are passed into the gasification device 7 as part of the gasification agent, and the semi-coke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com