System and method for pyrolysis of household refuses

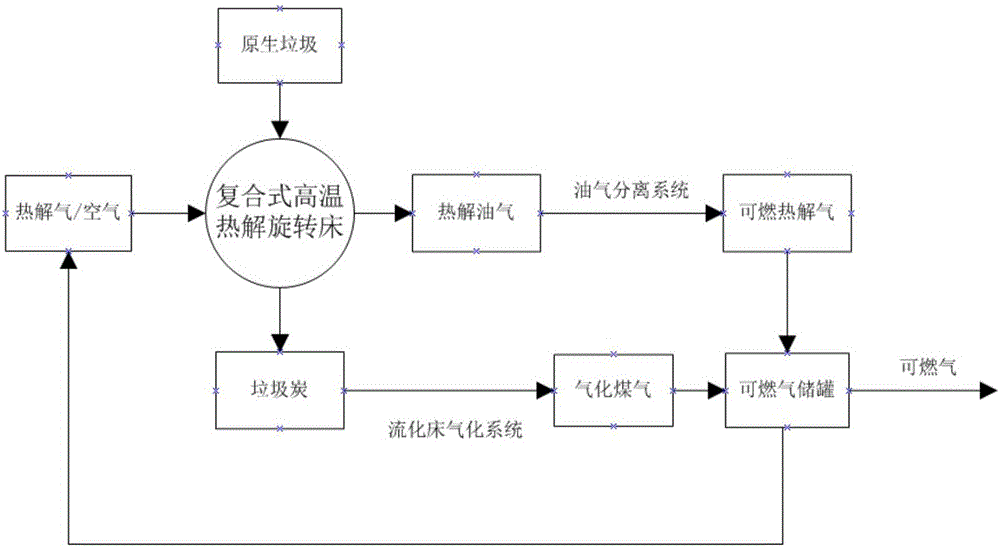

A domestic garbage and pyrolysis technology, which is applied in the field of solid waste recycling, can solve the problems of difficult utilization, poor economic benefits, industrialization, and difficulty in continuous and stable operation, so as to shorten the pyrolysis process, facilitate industrialization, and improve overall economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

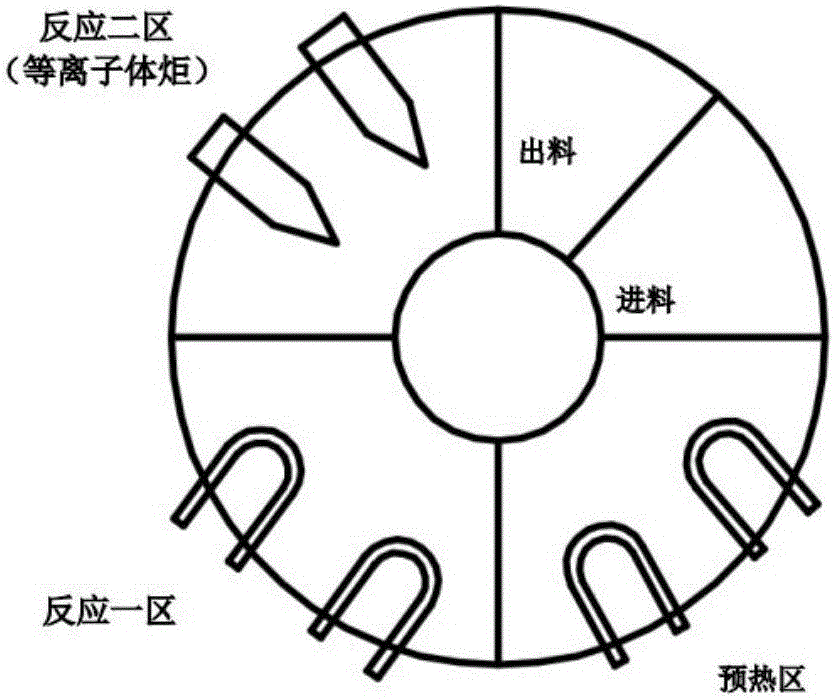

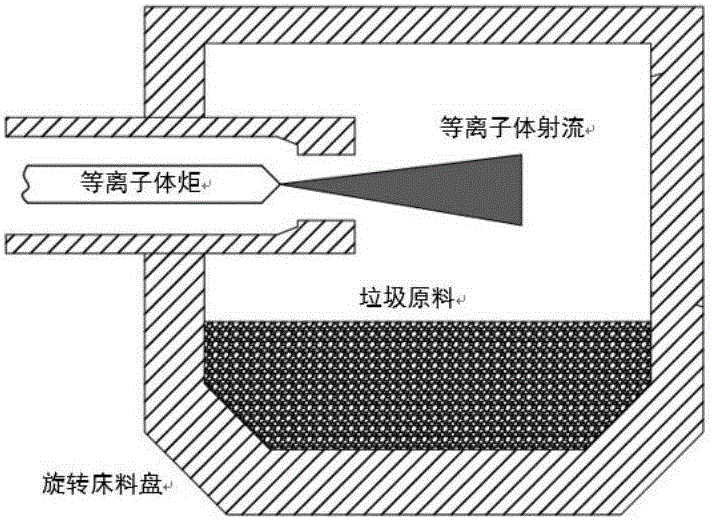

Method used

Image

Examples

Embodiment 1

[0057] The domestic garbage of a city is used as raw material, and the moisture content of the garbage is 45%. The composition is shown in Table 1.

[0058] Table 1 Household garbage composition (wt%)

[0059]

[0060] The composite high-temperature pyrolysis rotary bed increases the pyrolysis temperature of garbage, and the yield of pyrolysis gas is improved. Compared with the conventional radiant tube rotary bed, the composite rotary bed is used to pyrolyze garbage, and the yield of pyrolysis gas is increased by about 10%. . The specific distribution of the tertiary industry is shown in Table 2:

[0061] Table 2 Tertiary product distribution (wt%) of composite high temperature pyrolysis rotating bed and conventional radiant tube rotating bed

[0062]

[0063] 160Nm of combustible gas can be produced after pyrolysis per ton of waste 3 , its composition and calorific value are as follows, compared with the conventional radiant tube rotary bed, the calorific value of t...

Embodiment 2

[0067] Using domestic waste from a certain city as raw material, the water content of the waste is 55%, and its composition is shown in Table 4:

[0068] Table 4 domestic waste composition (wt%)

[0069]

[0070] The composite high-temperature pyrolysis rotating bed increases the pyrolysis temperature of garbage, and the yield of pyrolysis gas is improved. Compared with the conventional radiant tube rotating bed, the composite high-temperature pyrolysis rotating bed is used to pyrolyze garbage, and the yield of pyrolysis gas is increased. 8% or so. The specific distribution of the tertiary industry is shown in Table 5:

[0071] Table 5 Tertiary product distribution (wt%) of composite high temperature pyrolysis rotating bed and conventional radiant tube rotating bed

[0072]

[0073] 180Nm of combustible gas can be produced after pyrolysis per ton of waste 3 , its composition and calorific value are as follows. Compared with the conventional radiant tube rotary bed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com