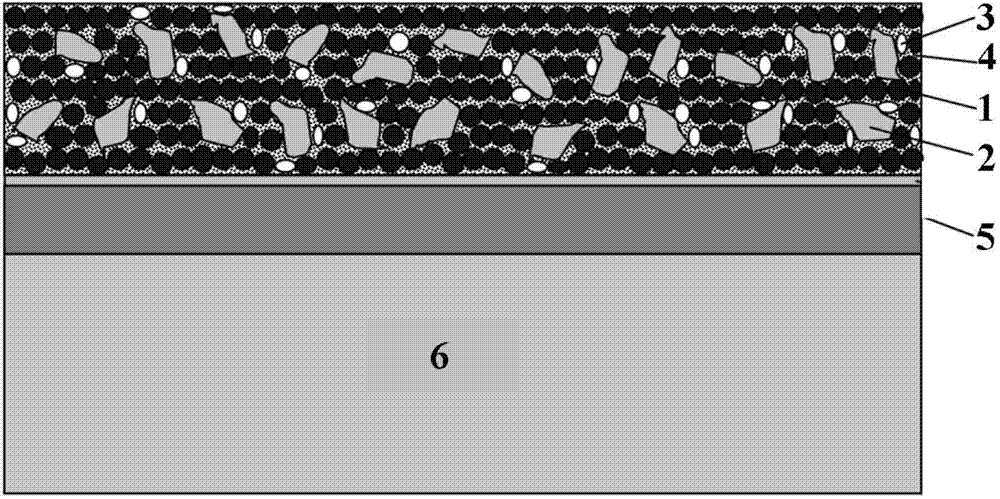

Four-phase ceramic matrix high-temperature wearable sealing coating

A sealing coating and ceramic-based technology, which is applied in coatings, metal material coating technology, sustainable transportation, etc., can solve problems such as cracking, peeling, and failure of sealing coatings, and achieve relaxation of thermal stress and improvement of mechanical properties , high temperature stability and thermal shock resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 10wt% Al with a particle size of 20-40nm 2 o 3 The powder was mechanically mixed with DySZ+h-BN+polyester three-phase abradable powder for 12 hours to obtain a four-phase abradable composite powder for use. Use 46 mesh corundum sand to roughen the surface to be sprayed. The supersonic flame spraying process was used to spray NiCoCrAlY alloy powder on the surface of the roughened substrate to prepare the bonded bottom layer, with a thickness of about 150 μm. Spray doped nm-Al on the bonded underlayer by plasma spraying process 2 o 3 Four-phase ceramic-based high-temperature abradable sealing coating, the spraying parameters are: current 620A, voltage 70V, spraying distance 120mm, and the thickness of the sprayed coating is about 1000μm. Three-phase abradable sealing coating of DySZ+h-BN+polyester and doped nm-Al 2 o 3 The test results of the thermal shock resistance of the four-phase abradable sealing coating at 1150°C show that the addition of 10wt% fourth-phase n...

Embodiment 2

[0025] 5wt% SiO with a particle size of 20nm 2 The powder was mechanically mixed with DySZ+h-BN+polyester three-phase abradable powder for 8 hours to obtain a four-phase abradable composite powder for use. Use 46 mesh corundum sand to roughen the surface to be sprayed. NiCrAlY alloy powder was sprayed on the surface of the roughened substrate by detonation spraying process to prepare the bonded bottom layer with a thickness of about 150 μm. Spray doped nm-SiO on the bonded underlayer by plasma spraying process 2 Four-phase ceramic-based high-temperature abradable sealing coating. The spraying parameters are: current 600A, voltage 70V, spraying distance 100mm, and the thickness of the sprayed coating is about 1000μm. Three-phase abradable sealing coating of DySZ+h-BN+polyester and doped nm-Al 2 o 3 The test results of the thermal shock resistance of the four-phase abradable sealing coating at 1150°C show that the addition of 5wt% fourth-phase nano-SiO 2 The thermal shock r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com