Method for extracting tungsten from alkaline crude sodium tungstate solution without renewable recyclable extracting system

A crude sodium tungstate extraction technology, which is applied in the field of tungsten hydrometallurgy, can solve the problems that the regeneration liquid cannot be directly returned to the main process, the cost of the process is short, and the consumption of large alkali, etc., to achieve the effect of saving the regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Feed liquid: The feed liquid is low-grade scheelite soda high-pressure leaching liquid, of which WO 3 10.0g / L, P0.10g / L, As0.02g / L, Si0.1g / L, Na 2 CO 3 21.5g / L.

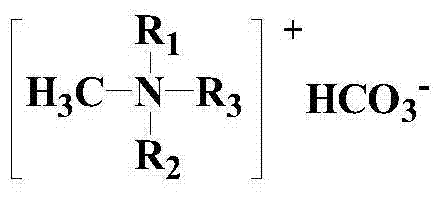

[0036] Organic phase: The organic phase is 60% methyl trioctyl ammonium chloride + 25% 2-octanol + 15% sulfonated kerosene (volume percentage). Before extraction, pre-mix the organic phase with 2.5mol / L NH 4 HCO 3 -1.0mol / L(NH 4 ) 2 CO 3 Mixed ammonium solution is carried out multi-stage cross-flow treatment by comparing 2 / 1, makes the methyl trioctyl ammonium chloride in the organic phase completely convert to the bicarbonate of methyl trioctyl ammonium and the mixture of carbonate, wherein The molar ratio of bicarbonate to carbonate is about 8:1.

[0037] Operation: The above-mentioned organic phase and feed liquid are subjected to 8-stage countercurrent extraction at a flow ratio of 1 / 10, and the negative tungsten organic phase is subjected to 3-stage countercurrent washing with deionized water at a...

Embodiment 2

[0040] Feed liquid: Feed liquid is wolframite sodium hydroxide leaching liquid, in which WO3300.0g / L, P1.50g / L, As0.70g / L, Si0.75g / L, NaOH70g / L.

[0041] Organic phase: The organic phase is 25% N263 + 20% 2-octanol + 55% aviation kerosene (volume percentage). N263 is the product code of domestic quaternary ammonium salt extractant, which is a kind of methyl trialkylammonium chloride, in which the carbon atoms in the three alkyl groups are 8-10 respectively. The organic phase was mixed with 1.0mol / L NH several times before extraction 4 HCO 3 -0.5mol / L(NH 4 ) 2 CO 3 The mixed ammonium solution is contacted to convert the methyltrialkylammonium chloride in the organic phase to a mixture of bicarbonate and carbonate of methyltrialkylammonium, wherein the molar ratio of bicarbonate to carbonate is about 6 :1.

[0042] Operation: The above organic phase and feed liquid are subjected to 15-stage countercurrent extraction under the condition of a flow ratio of 10 / 1, and the nega...

Embodiment 3

[0045] Feed liquid: The feed liquid is scheelite soda high pressure leaching liquid, in which WO 3 130.3g / L, P0.020g / L, As0.012g / L, Si0.035g / L, Na 2 CO 3 100.2g / L.

[0046] Organic phase: The organic phase is 10% methyl trinonyl ammonium chloride + 20% sec-octanol + 70% No. 260 solvent oil (volume percentage). Before the extraction, the organic phase was mixed with 2.2mol / L NH 4 HCO 3 -1.2mol / L(NH 4 ) 2 CO 3 The mixed ammonium solution is contacted to convert the methyltrinonylammonium chloride in the organic phase into a mixture of bicarbonate and carbonate of methyltrinonylammonium, wherein the molar ratio of bicarbonate to carbonate is about 5.5 :1.

[0047] Operation: The above-mentioned organic phase and the feed liquid are subjected to 9-stage countercurrent extraction at a flow ratio of 8 / 1, and the negative tungsten organic phase is subjected to 5-stage countercurrent washing with deionized water at a flow ratio of 6 / 1, and then washed with 2.2mol / L NH 4 HCO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com