Methyl silicate stone protecting agent and manufacturing method thereof

A technology of methyl silicate and manufacturing method, applied in the direction of coating and the like, can solve the problems such as unsurmountable, long curing time, etc., and achieve the effects of firm bonding, fast curing time, and easy operation of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

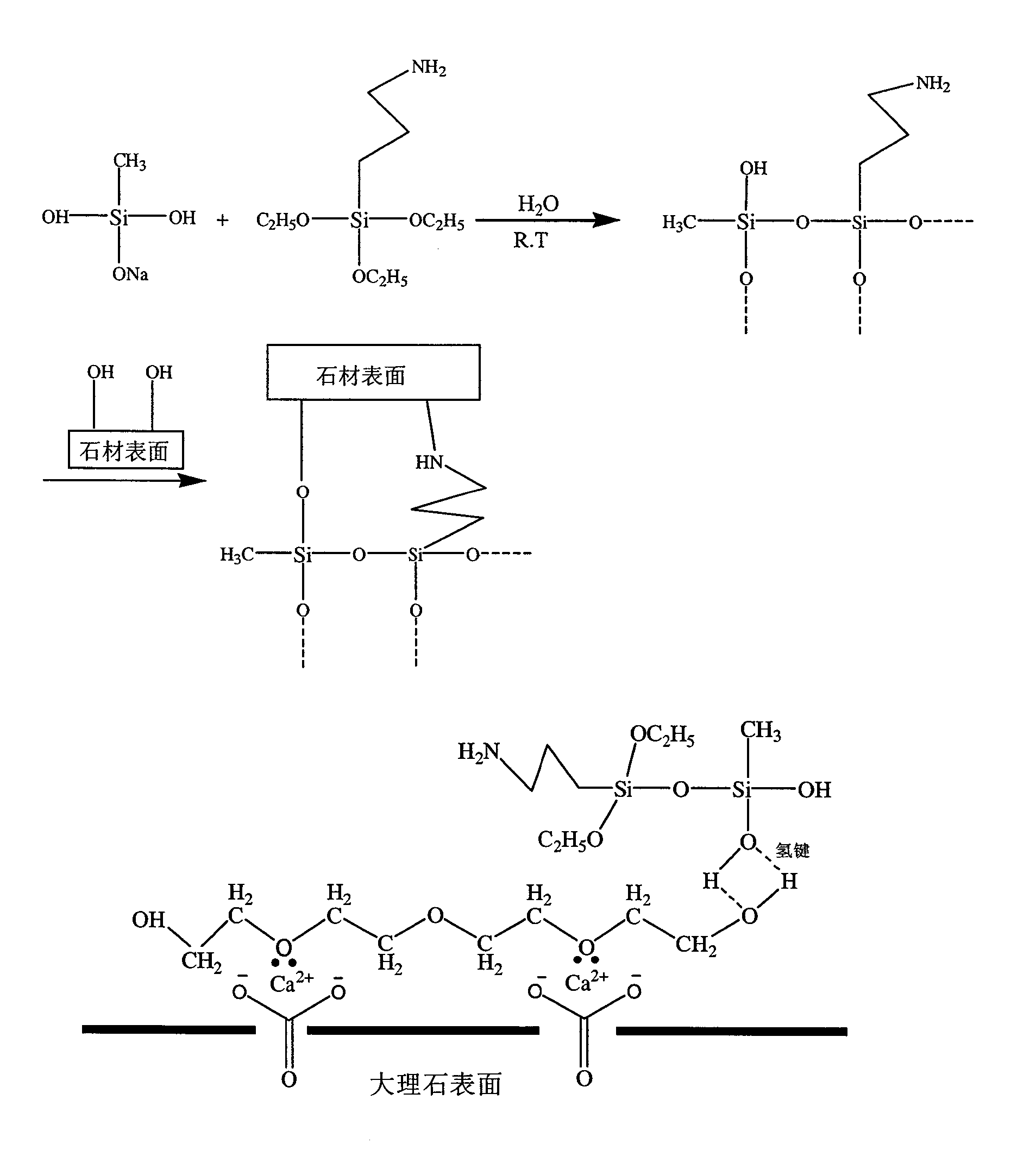

Method used

Image

Examples

Embodiment 1

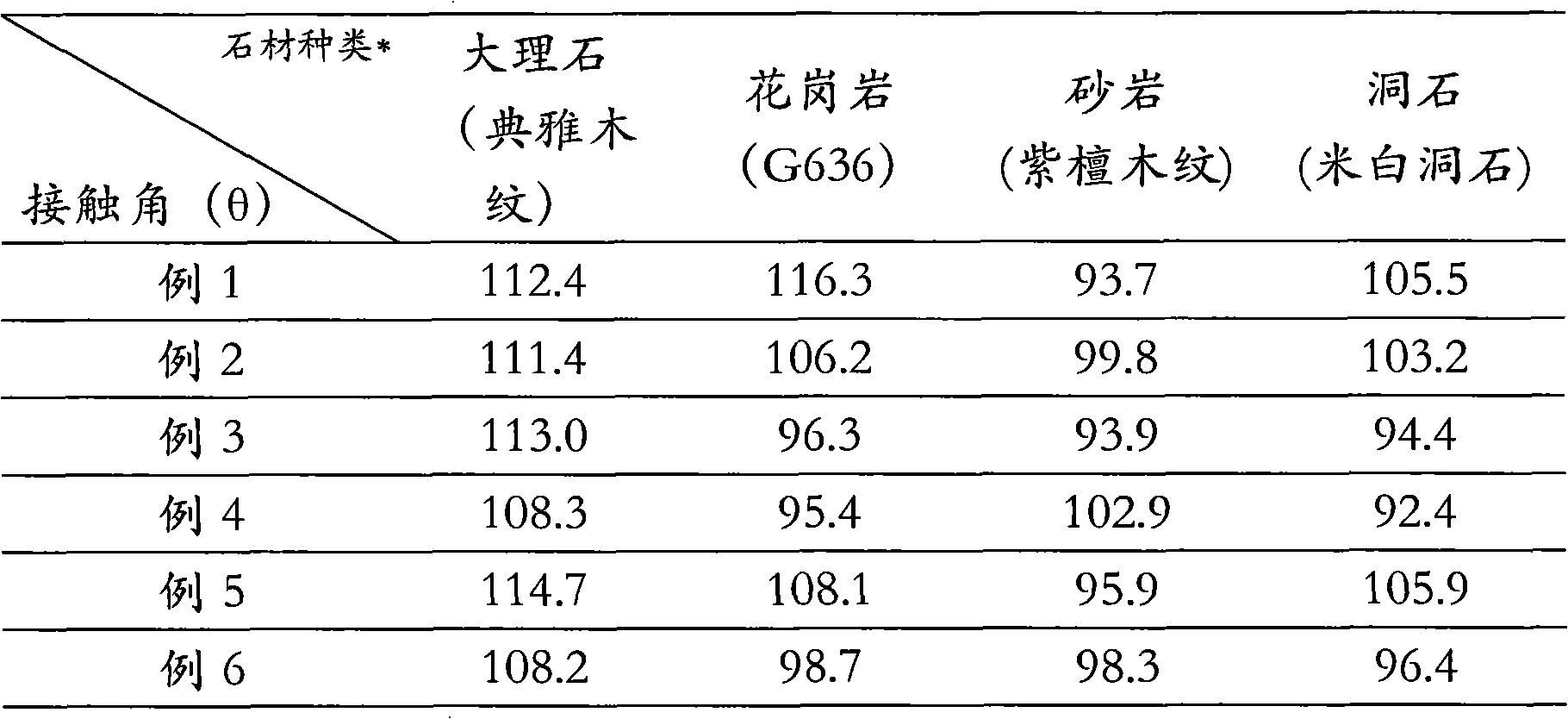

[0038] First add 120g of sodium methyl silicate and 14.2g of silane coupling agent KH-550 to 200mL of water under stirring, and after stirring for a period of time at room temperature, add water to 1000mL. Paint on marble, granite, sandstone and travertine respectively, measure the contact angle, record as example 1.

Embodiment 2

[0040] First add 120g of sodium methyl silicate and 21.1g of silane coupling agent KH-550 to 200mL of water under stirring, and after stirring for a period of time at room temperature, add water to 1000mL. Paint on marble, granite, sandstone and travertine respectively, measure the contact angle, record as example 2.

Embodiment 3

[0042] Dissolve 10g of polyethylene glycol (PEG 2000) in 200mL of deionized water, then add 86g of sodium methyl silicate and 28g of silane coupling agent KH-550 to it while stirring, and then add water to 1000mL. Paint on marble, granite, sandstone and travertine respectively, measure the contact angle, record as example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com