Preparation process for high-quality instant red tea

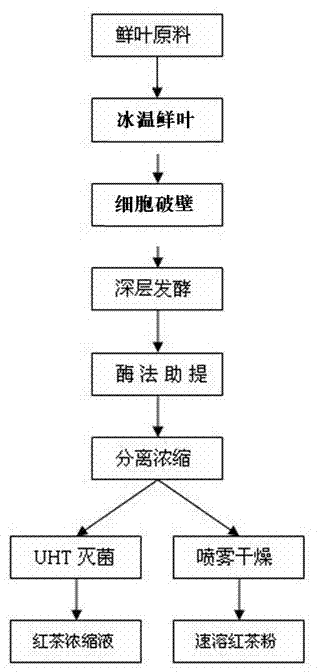

A technology for instant black tea and preparation process, applied in the field of deep processing of tea leaves, can solve the problems of lack of characteristic components, short production cycle, loss of quality, etc., and achieve the effects of pure aroma, short production process, and bright orange-yellow soup color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (a) Collect fresh leaves and wither in a ventilator at 20°C for 16 hours, then treat them at -30°C at ice temperature to obtain ice-temperature fresh leaves;

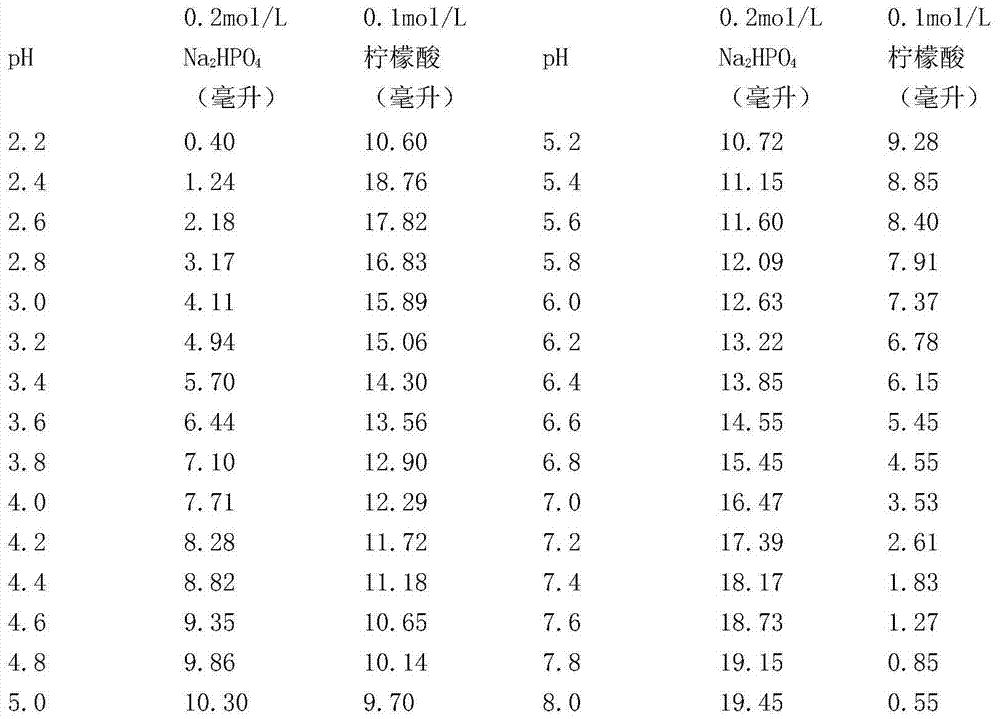

[0032] (b) Add pH 4.6 citric acid-disodium hydrogen phosphate buffer solution to ice-temperature fresh leaves according to the solid-to-liquid ratio of 1 g: 20 ml (w / v), homogenize for 2 minutes, and homogenize at a temperature of 15° C. to obtain a homogenate;

[0033] (c) Put the homogenate into a temperature-controlled reactor with an air flow rate of 2.0 L / min to ferment for 40 minutes at 35° C., and then keep it at 100° C. for 3 minutes to obtain a fermentation broth.

[0034] (d) Cool the fermentation broth to 30°C, adjust the pH of the solution to 5.0, add a mixture of cellulase and pectinase for extraction, wherein the mass ratio of cellulase and pectinase is 1:1, and the cellulase and pectinase The mass volume ratio of the pectinase mixture to the fermentation broth is 1.0g: 100ml, the extraction time is...

Embodiment 2

[0038] (a) Collect fresh leaves and wither in a 25°C ventilator for 12 hours, then treat them at -28°C at ice temperature to obtain ice-temperature fresh leaves;

[0039] (b) Add pH 4 citric acid-disodium hydrogen phosphate buffer solution to ice-temperature fresh leaves according to the solid-to-liquid ratio of 1 g: 20 ml (w / v), homogenize for 3 minutes, and homogenize at a temperature of 10° C. to obtain a homogenate;

[0040] (c) Put the homogenate into a temperature-controlled reactor with an air flow rate of 3.0 L / min and ferment for 30 minutes at 30°C, and then keep at 90°C for 5 minutes to obtain a fermentation broth.

[0041] (d) Cool the fermentation broth to 35°C, adjust the pH of the solution to 5.5, add a mixture of pectinase and glycosidase for extraction, the mass volume ratio of the biological enzyme mixture to the fermentation broth is 0.75g: 100ml, and the extraction time is 120min Afterwards, the temperature was raised to 90°C and kept for 10 minutes to obtai...

Embodiment 3

[0045] (a) Collect fresh leaves and wither in a ventilator at 25°C for 20 hours, then treat them at -20°C at ice temperature to obtain ice-temperature fresh leaves;

[0046](b) Add pH 6 citric acid-disodium hydrogen phosphate buffer solution to ice-temperature fresh leaves according to the solid-to-liquid ratio of 1 g: 20 ml (w / v), homogenize for 5 minutes, and homogenize at a temperature of 15° C. to obtain a homogenate;

[0047] (c) Put the homogenate into a temperature-controlled reactor with an air flow rate of 1.5 L / min and ferment for 90 minutes at 25° C., and then keep it at 95° C. for 5 minutes to obtain a fermentation broth.

[0048] (d) Cool the fermentation broth to 25°C, adjust the pH of the solution to 6.5, add a mixture of cellulase and protease for extraction, the mass volume ratio of the biological enzyme mixture to the fermentation broth is 2.0g: 100ml, and the extraction time is 90min Raise the temperature to 95°C and keep for 5 minutes to obtain the extract;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com