Automatic tea leaf roasting machine and automatic tea leaf processing method thereof

A technology of frying machine and tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of large power consumption, large temperature fluctuation, unfavorable tea quality, etc., and achieve the effects of ensuring quality consistency, good tea quality and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

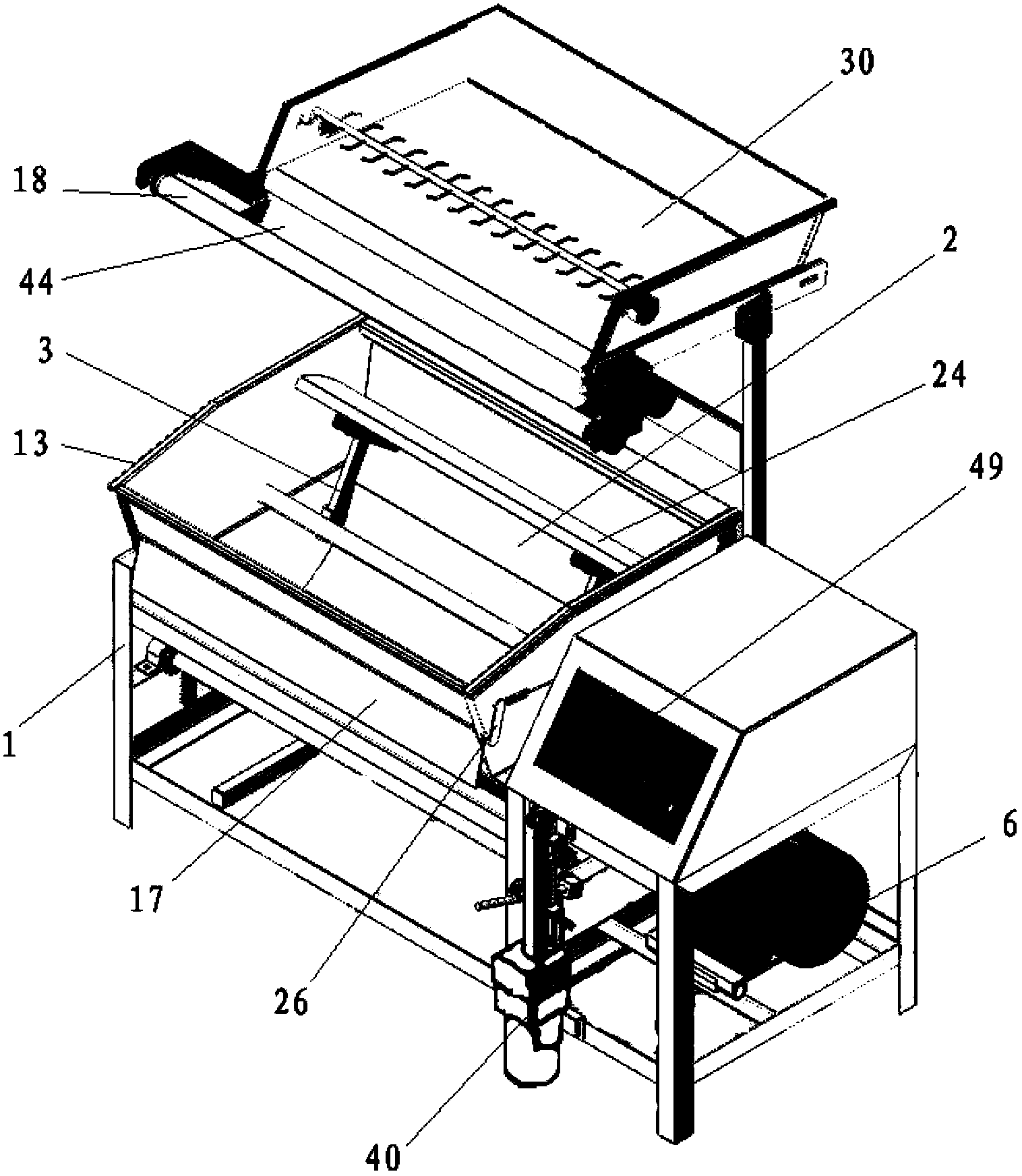

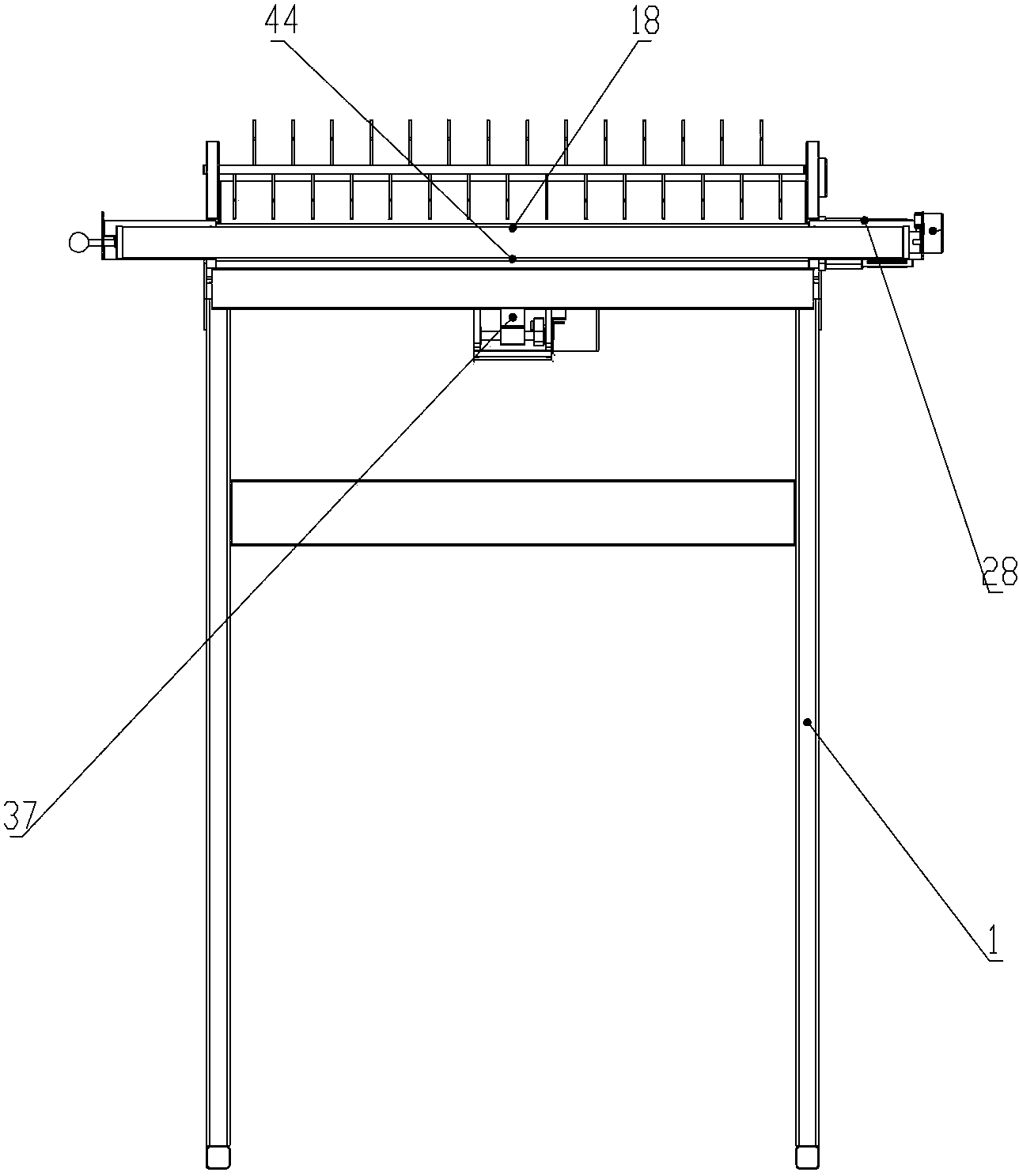

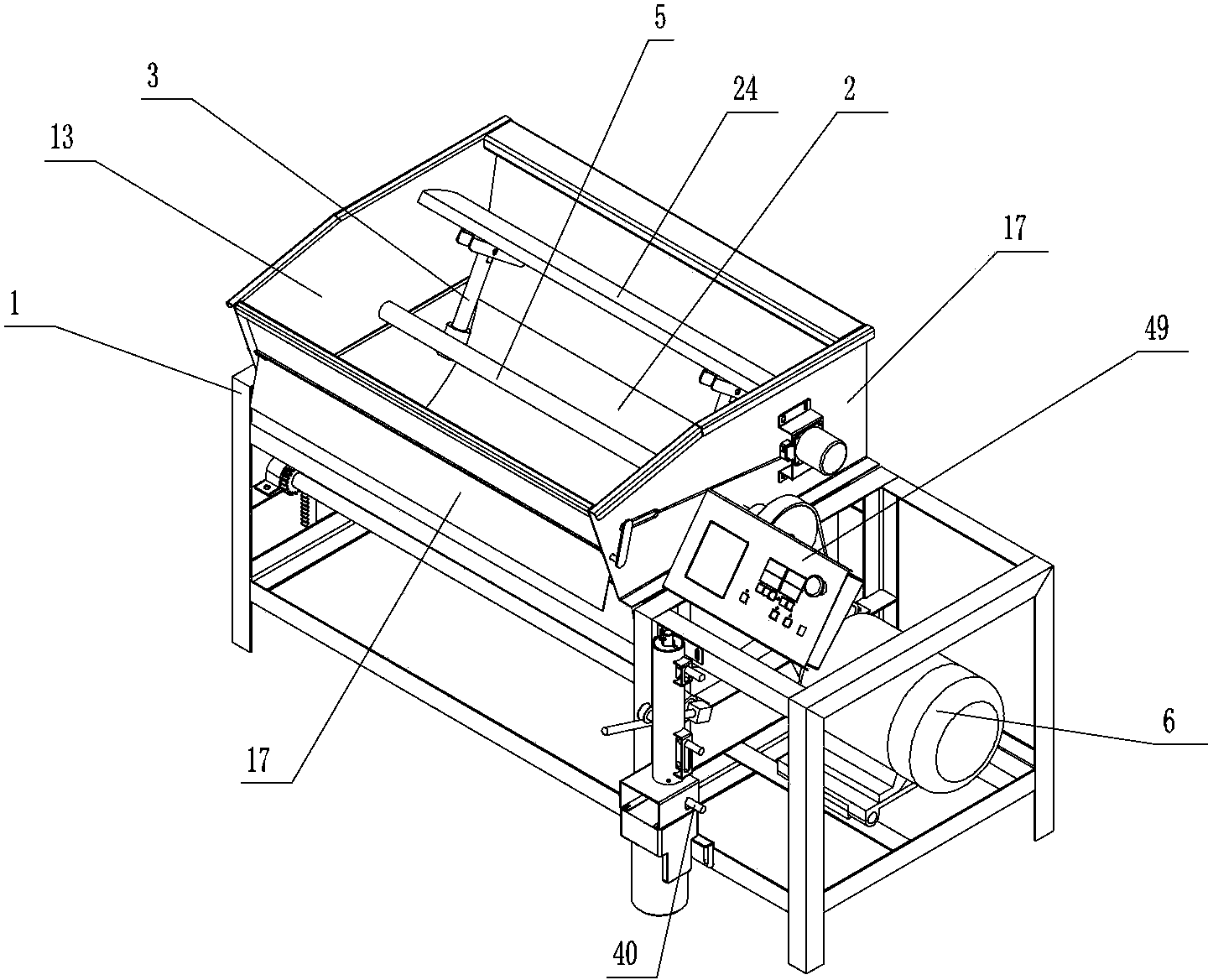

[0040] The tea automatic roasting machine of the present invention comprises a mechanical system, a power system and a control system. Among them, such as figure 1 As shown, the mechanical system includes a frame 1 , a feed hopper 30 , a main shaft 5 , a frying plate 24 , a frying pan 2 , an electric heater and a discharge plate 17 . The function of the frame 1 is to install other devices or parts in the present invention. The feed hopper 30 is arranged on the top of the frame 1, the main shaft 5 and the frying plate 24 are arranged inside the frying pan 2, the frying plate 24 is connected with the main shaft 5 through the connecting rod 3, and the connecting part between the connecting rod 3 and the main shaft 5 is fixed. If it cannot move, the connecting part of the connecting rod 3 and the frying plate 24 can rotate at a small angle, so as to achieve the effect of simulating mechanical frying hands turning over by hand. The electric heater is arranged at the bottom of the...

Embodiment 2

[0047] In Embodiment 2, the basic structure of the automatic tea frying machine of the present invention is the same as that of Embodiment 1, the main difference being that the main controller adopts an AVR microcomputer controller. The AVR microcomputer controller is a high-speed 8-bit single-chip microcomputer with a simplified instruction set developed by the Norwegian Design Center of ATMEL Company, referred to as AVR. After adopting the AVR microcomputer controller, the automatic tea roasting machine of the present invention can save 1024 sets of data and 3 sets of roasting process at the same time, and can simulate the process of tea roasting by a high-level tea technician, and can ensure that the roasted tea leaves quality consistency.

[0048] In order to bring into play the effect of the AVR microcomputer controller better, under the situation that the main controller of the automatic tea frying machine of the present invention adopts the AVR microcomputer controller,...

Embodiment 3

[0050] In embodiment 3, the basic structure of the automatic tea frying machine of the present invention is the same as that of embodiment 1, the main difference is that the temperature control device includes a temperature sensor and a temperature controller, and the thermocouple or thermal resistance in the temperature sensor is connected with the frying pan 2. contact, and the temperature controller is respectively connected with the temperature sensor and the main controller through the control circuit. The temperature controller calculates the heating power required by the automatic tea frying machine of the present invention according to the deviation between the actual temperature of the tea leaves and the target temperature, thereby further reducing the consumption of electric energy and effectively avoiding damage to the quality of tea leaves due to excessive temperature of the frying pan.

[0051] In order to better control the roasting process of tea leaves and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com