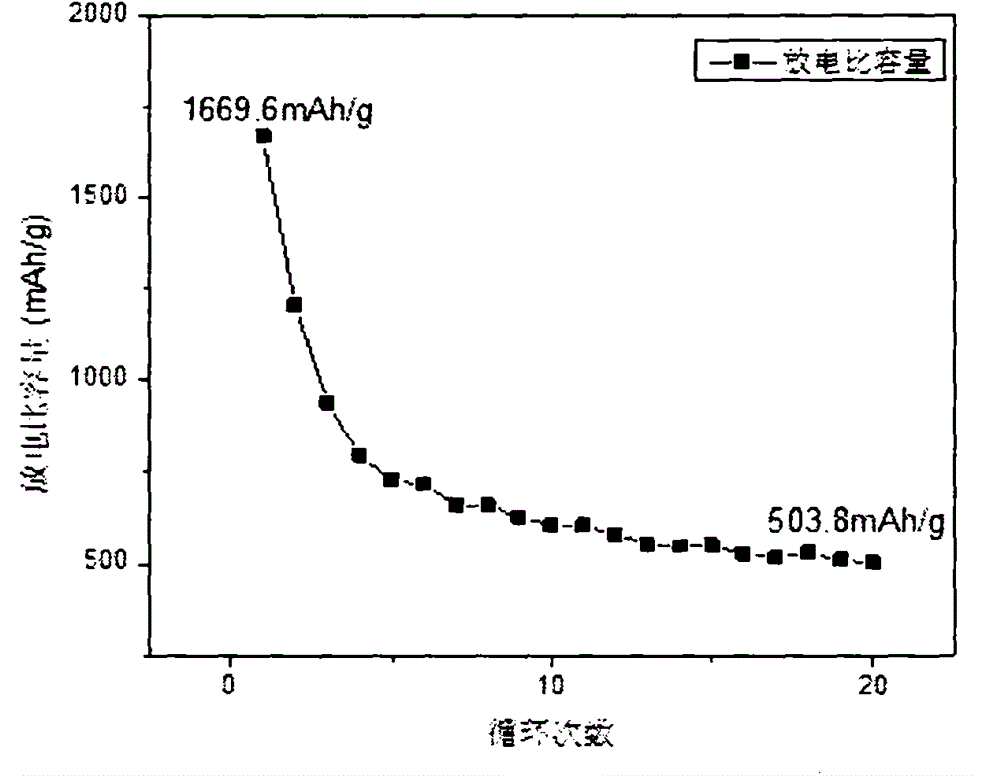

Composite lithium battery with high cycling stability and large capacity and preparation method thereof

A cycle stability and composite material technology, applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of volume change, tin electrode damage, electrode crushing and capacity attenuation, and achieve large capacity and cycle stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A composite lithium battery with high cycle stability and large capacity, the specific preparation method is as follows:

[0040] 1) Preparation of composite nanoparticles:

[0041] ①Preparation of water-soluble cationic polymer and water-soluble anionic polymer solution

[0042] Weigh 5.0g of polyaniline and dissolve it in 250ml of distilled water;

[0043] Weigh 5.0g polyethylene sulfonic acid and dissolve in 250ml distilled water;

[0044] ② Layer-by-layer self-assembly

[0045] a: Weigh 250mg of SnO with a particle size of 10-200nm 2 Nanoparticles, placed in a 30mL centrifuge tube;

[0046] b: Add 10 mL of the polyaniline solution prepared in step ① to the centrifuge tube, sonicate (stir) for 10 min, and then centrifuge and wash with deionized water for 3 to 5 times;

[0047] c: Add 10 mL of the polyethylene sulfonic acid solution prepared in step ① to the centrifuge tube, ultrasonic (stir) for 10 min, and then centrifuge and wash with deionized water for 3 to ...

Embodiment 2

[0062] A composite lithium battery with high cycle stability and large capacity, the specific preparation method is as follows:

[0063] 1) Preparation of composite nanoparticles:

[0064] ①Preparation of water-soluble cationic polymer and water-soluble anionic polymer solution

[0065] Weigh 5.0g of polyethyleneimine and dissolve it in 250ml of distilled water;

[0066] Weigh 5.0g of polyacrylamide and dissolve it in 250ml of distilled water;

[0067] ② Layer-by-layer self-assembly

[0068] a: Weigh 250mg of SiO with a particle size of 10-200nm 2 Nanoparticles, placed in a 30mL centrifuge tube;

[0069] b: Add 10 mL of the polyethyleneimine solution prepared in step ① to the centrifuge tube, ultrasonic (stir) for 10 min, and then centrifuge and wash with deionized water for 3 to 5 times;

[0070] c: Add 10 mL of the polyacrylamide solution prepared in step ① to the centrifuge tube, sonicate (stir) for 10 min, and then centrifuge and wash with deionized water for 3 to 5 t...

Embodiment 3

[0084] A composite lithium battery with high cycle stability and large capacity, the specific preparation method is as follows:

[0085] 1) Preparation of composite nanoparticles:

[0086] ①Preparation of water-soluble cationic polymer and water-soluble anionic polymer solution

[0087] Weigh 5.0g of cationic polyacrylamide and dissolve it in 250ml of distilled water;

[0088] Weigh 5.0g polystyrene sulfonic acid and dissolve it in 250ml distilled water;

[0089] ② Layer-by-layer self-assembly

[0090] a: Weigh 250mg of GeO with a particle size of 10-200nm 2 Nanoparticles, placed in a 30mL centrifuge tube;

[0091] b: Add 10 mL of the cationic polyacrylamide solution prepared in step ① to the centrifuge tube, sonicate (stir) for 10 min, and then centrifuge and wash with deionized water for 3 to 5 times;

[0092] c: Add 10 mL of the polystyrene sulfonic acid solution prepared in step ① to the centrifuge tube, sonicate (stir) for 10 min, and then centrifuge and wash with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com