Rock breaking simulation test system and method coupled with tbm hob and high pressure water jet

A simulation test system and high-pressure water jet technology, applied in the field of tunnel engineering, can solve problems such as poor slag discharge effect in the rock breaking process, affecting the observation of rock breaking effect, affecting continuous cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

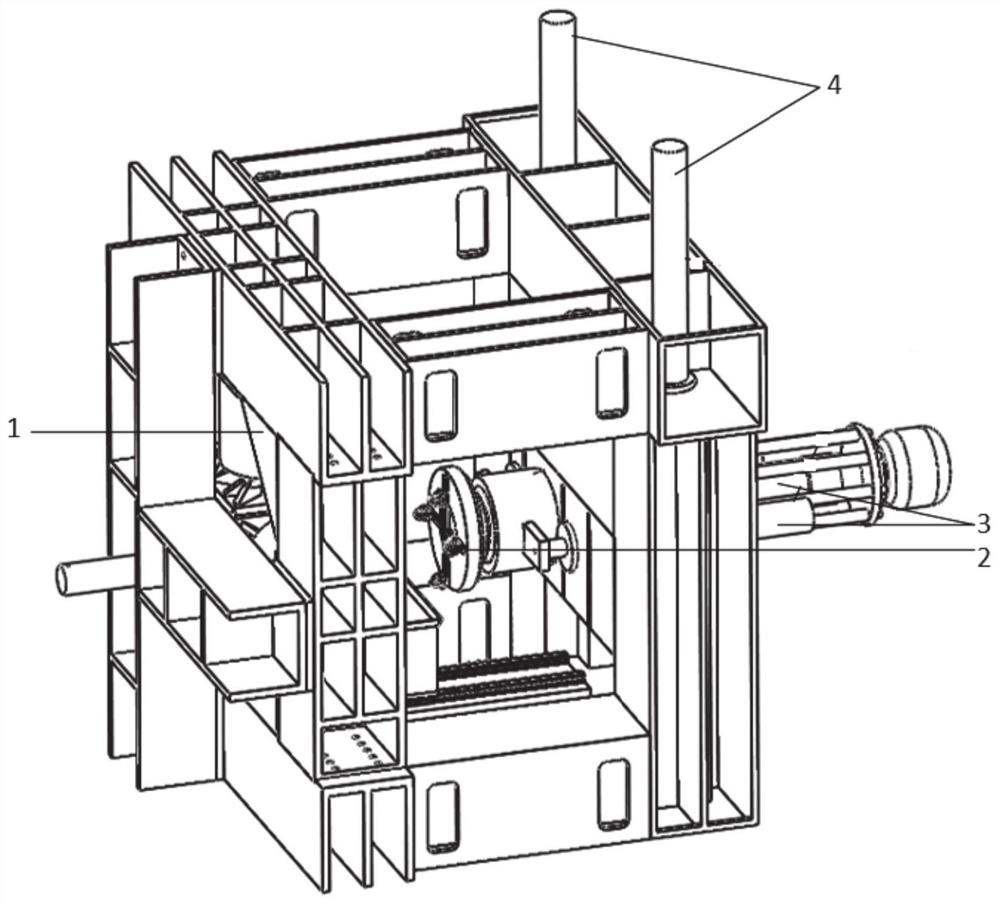

[0052] Such as figure 1 As shown, a rock-breaking simulation test system coupled with a TBM hob and high-pressure water jet has a three-dimensional reaction force frame 1 as the main structure, as shown in figure 2 As shown, the structure of the three-dimensional reaction force frame 1 specifically includes: a front door frame 1-1, a reaction force beam 1-2, a rear door frame 1-3, a movable beam 1-4, a connecting beam 1-5, and a load-carrying mobile tray 1-6, the front portal frame 1-1 and the rear portal frame 1-3 are connected as a whole through the connecting beam 1-5, wherein the front portal frame 1-1 is provided with two-way hydraulic cylinders and corresponding push plates, and the front portal frame 1 -1 The front part is provided with a reaction beam 1-2, on which a horizontal oil cylinder is installed, and the bottom beam of the front door frame 1-1 is provided with a load-bearing mobile pallet 1-6, and the rock specimen is installed on the load-bearing mobile palle...

Embodiment 2

[0074] The difference from the above-mentioned embodiment is that, if Figure 5 , Image 6 As shown, the rotary rock-breaking cutter head of this embodiment is a guide rail type rotary rock-breaking cutter head 2, which specifically includes a cutter head 2-1, a rotating power motor 2-2, a hob 2-4, a hob guide rail 2-5, Fixed support 2-6, movable nozzle support 2-7 and high-pressure jet nozzle 2-8.

[0075] Some hob guide rails 2-5 ( Figure 5 In the middle are two cross guide rails, which are finally a cross, but in other embodiments, the number and combination of the guide rails and the shape formed can be changed), the hob 2-4 is installed through a freely slidable fixed support 2-6 On the guide rail, the high-pressure jet nozzle 2-8 is installed on the side of the hob through the nozzle bracket 2-7.

[0076] The nozzle holder 2-7 can be as Image 6 The shown fixed type can also be a liftable support or a rotatable adjustable support composed of several poles. The heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com