A production process of wallpaper with handmade three-dimensional effect

A technology of three-dimensional effect and production process, applied in inks, household appliances, covering/lining, etc., can solve the problems of not being able to better highlight the three-dimensional effect, the incomparable three-dimensional effect of manual embossing, and limiting the designer's design space, etc. Achieve the effect of enhancing the three-dimensional effect of the pattern, reducing the production process, and enhancing the sense of touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

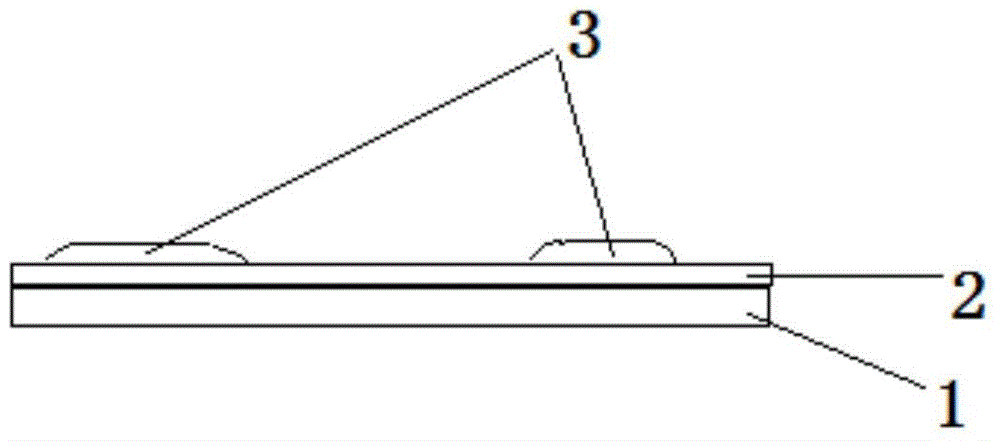

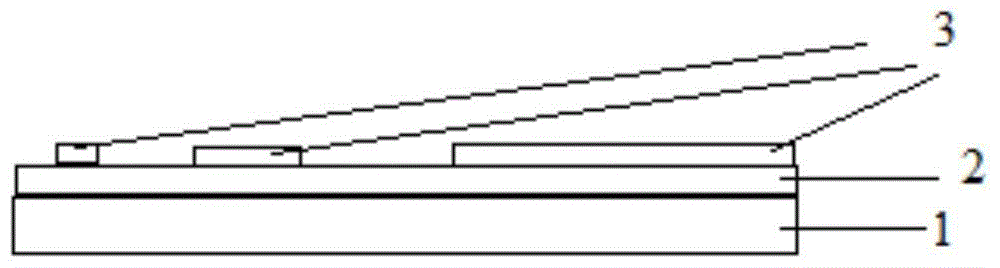

[0034] The pattern in the present embodiment is the wallpaper of manual three-dimensional effect, and its structure is as mentioned above, and its manufacturing process is as follows:

[0035] The ground color is printed on the bottom layer to form a ground color layer, and then patterns are printed on the ground color layer by rotary screen printing to form a pattern decoration layer.

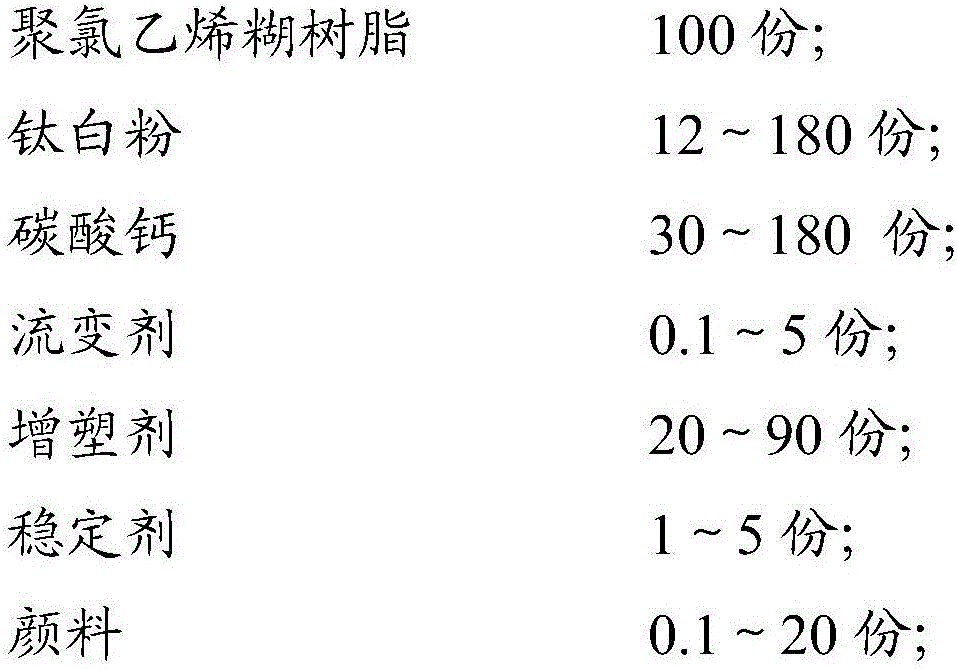

[0036] Wherein, when printing patterns, the slurry used is made of the following weight ratio substances:

[0037]

[0038]

[0039] The specific production process is as follows:

[0040] Add plasticizer and stabilizer to the mixing tank, stir evenly to form a mixed solution, then add titanium dioxide, calcium carbonate and rheological agent to the mixed solution and stir well, then add polyvinyl chloride paste resin into the mixing tank, control Rotate at 2400r / min, stir for 22min, finally add the pigment into the mixing tank, stir evenly, adjust the viscosity to 340000cps, and set it...

Embodiment 2

[0047] The pattern in the present embodiment is the wallpaper of manual three-dimensional effect, and its structure is as mentioned above, and its manufacturing process is as follows:

[0048] The ground color is printed on the bottom layer to form a ground color layer, and then patterns are printed on the ground color layer by rotary screen printing to form a pattern decoration layer.

[0049] Wherein, when printing patterns, the slurry used is made of the following weight ratio substances:

[0050]

[0051]

[0052] The specific production process is as follows:

[0053] Add plasticizer and stabilizer to the mixing tank, stir evenly to form a mixed solution, then add titanium dioxide, calcium carbonate and rheological agent to the mixed solution and stir well, then add polyvinyl chloride paste resin into the mixing tank, control The rotation speed is 900r / min, and it is stirred for 28 minutes. Finally, add the pigment into the mixing bucket, stir evenly, adjust the vi...

Embodiment 3

[0060] The pattern in the present embodiment is the wallpaper of manual three-dimensional effect, and its structure is as mentioned above, and its manufacturing process is as follows:

[0061] The ground color is printed on the bottom layer to form a ground color layer, and then patterns are printed on the ground color layer by rotary screen printing to form a pattern decoration layer.

[0062] Wherein, when printing patterns, the slurry used is made of the following weight ratio substances:

[0063]

[0064]

[0065] The specific production process is as follows:

[0066] Add plasticizer and stabilizer to the mixing tank, stir evenly to form a mixed solution, then add titanium dioxide, calcium carbonate and rheological agent to the mixed solution and stir well, then add polyvinyl chloride paste resin into the mixing tank, control The rotation speed is 2500r / min, and it is stirred for 20 minutes. Finally, the pigment is added into the mixing tank, stirred evenly, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com