Poor oxygen resistance high density fermentation natamycin gene engineering strain constructed by using vgb gene, and application thereof

A genetically engineered strain and high-density fermentation technology, applied in the field of genetic engineering, can solve problems such as low local dissolved oxygen concentration, slowed bacterial growth, and high oxygen consumption, so as to improve oxygen supply shortage, reduce production costs, and improve production efficiency. The effect of oxygen uptake capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

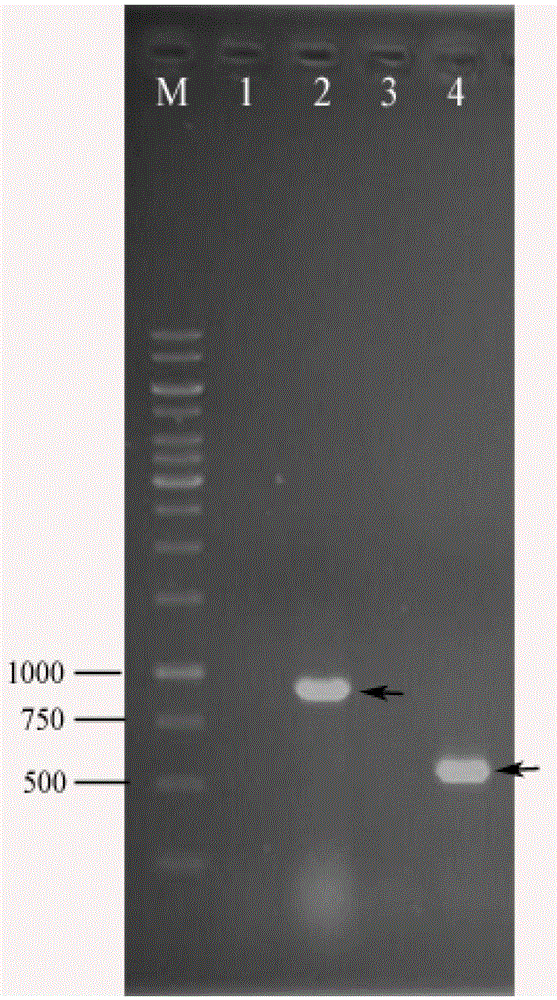

[0024] Construction of recombinant plasmid pSET152-vgb.

[0025] (1) According to the sequence of vgb gene and its promoter included in GenBank (NO.M30794.1), design upstream and downstream primers respectively:

[0026] Upstream primer vgbL: 5'-GGC GAATTC AGTTTTAAAGAGGCAAT-3' (underlined as EcoRI restriction site); downstream primer vgbR: 5'-CT TCTAGA TTATTCAACCGCTTGAGCGTAC-3' (underlined as XbaI restriction site).

[0027] p BBR -MCS5-vgb was used as a template, and the vgb gene and its promoter sequence were obtained by PCR amplification.

[0028] (2) The PCR product and the vector pSET152 were digested with EcoRI / XbaI respectively, after gel cutting and recovery, they were mixed at a molar ratio of 3:1 to 10:1, added with T4 ligase, and ligated overnight at 16°C. Connecting solution with CaCl 2 The E. coli competent cells E.coli ET12567 prepared by the method were mixed evenly, heat-shocked at 42°C for 90s, and cultured at 37°C for 1 hour, and then coated with LB so...

Embodiment 2

[0030] The construction of recombinant vgb gene Streptomyces chrysanthosporium adopts the mode of Escherichia coli-Streptomyces indirect conjugative transfer, and the specific steps are as follows:

[0031] (1) Pick a single colony of Escherichia coli E. coli ET12567 containing the recombinant plasmid pSET152-vgb in LB medium (containing 25 μg / mL of kanamycin, 25 μg / mL of chloramphenicol and 50 μg / mL of Amp Mycin), cultured overnight at 37°C with shaking.

[0032] (2) Transfer the overnight activated recombinant E.coli ET12567 into fresh LB medium (containing kanamycin, chloramphenicol and apramycin) at 2% inoculum size, and culture at 37°C until OD 600 =0.4~0.6, centrifuge, wash the bacteria twice with equal volume of LB medium, resuspend in 0.1 times volume of LB medium;

[0033] (3) While processing recombinant E.coli ET12567, take about 10 8 Put the spores of Streptomyces chrysosporium in 500 μl 2×YT culture concentrate, heat shock at 50°C for 10 minutes and then cool do...

Embodiment 3

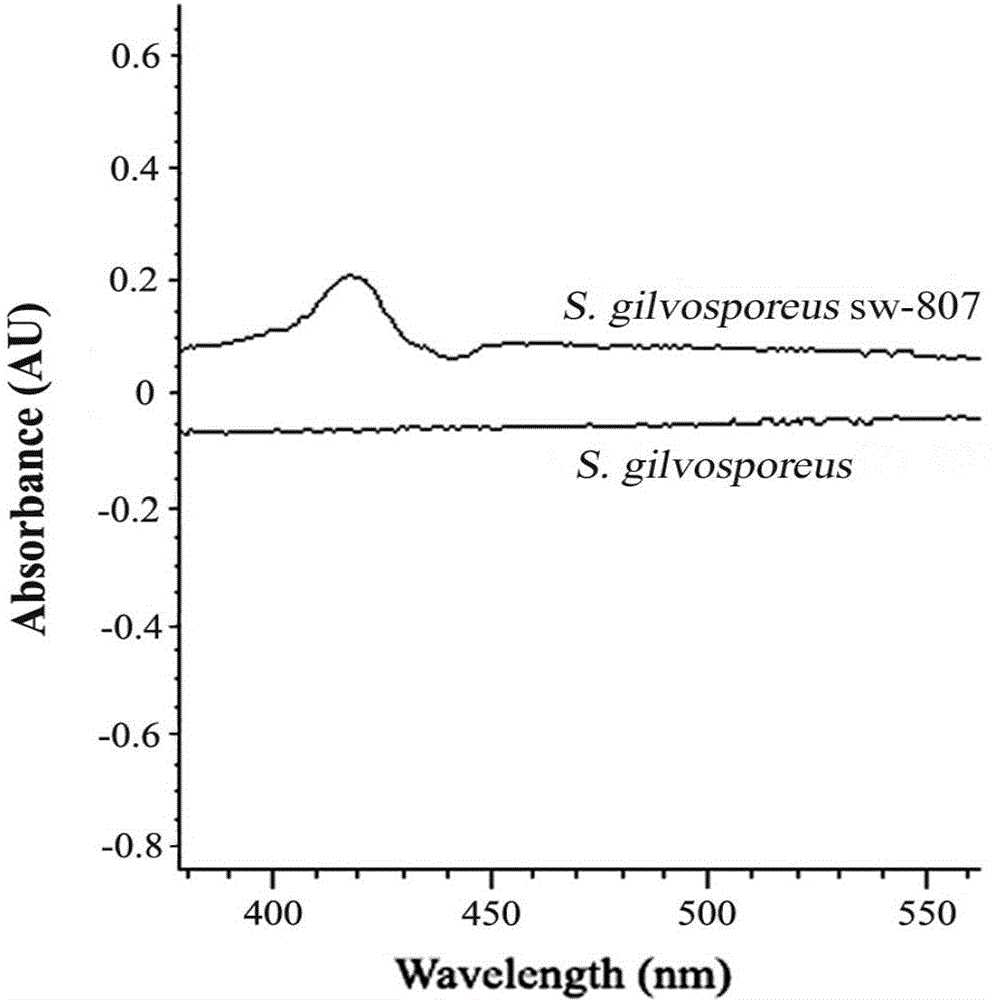

[0041] Application of S.gilvosporeus sw-807 in natamycin fermentation.

[0042] Wash the slanted spores of S. gilvosporeus S. gilvosporeus and recombinant bacteria S. gilvospores sw-807 with sterile water to make a spore suspension (about 10 8 each / mL); inoculate into 5mL seed culture medium according to 2%~5% inoculum amount, shake and cultivate at 28~30°C for 48h; 16 to 20 hours; then transfer 2% to 5% of the inoculum to a 250mL Erlenmeyer flask containing 30mL and 50mL of fermentation medium, and ferment for 3 to 5 days at 28 to 30°C with a rotational speed of 200 to 300r / min.

[0043] After the fermentation, the activity of VHb and the yield of natamycin were measured respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com