Preparation method of singe matrix LED (light-emitting diode) fluorescent powder

A phosphor, single-matrix technology, applied in the field of single-matrix LED phosphor preparation, can solve the problems of low luminous efficiency, the luminous efficiency does not reach practical application value, the effect of the lumen efficiency of the phosphor and the color reproducibility, etc., and achieves high luminous efficiency. , the preparation method is easy to operate, and the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

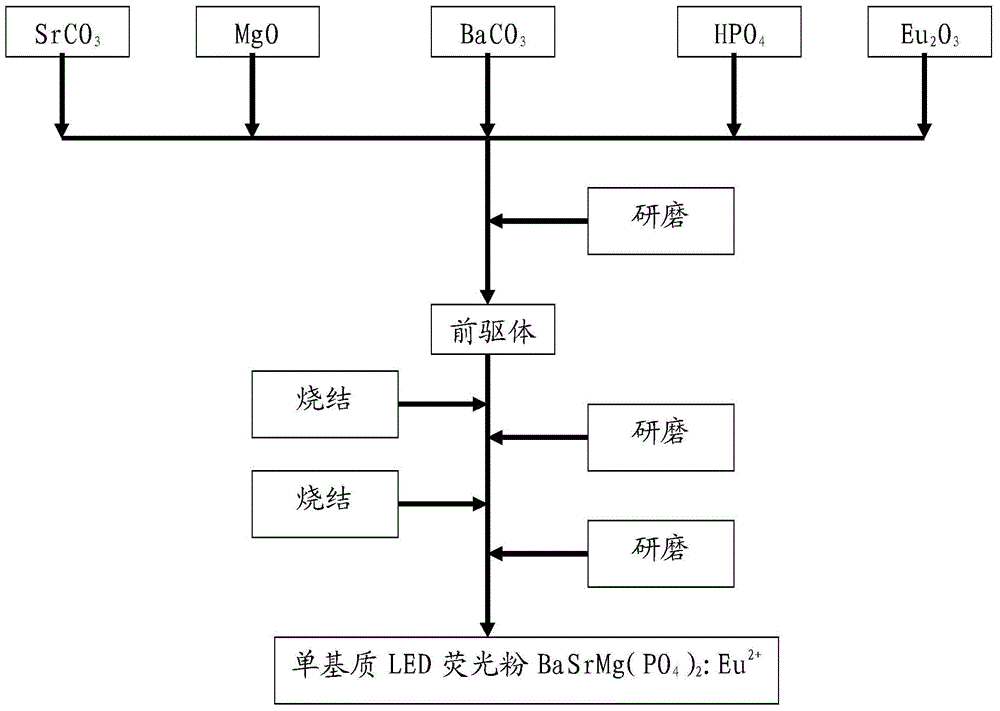

[0017] Such as figure 1 Shown, a kind of single-matrix LED phosphor preparation method comprises the steps:

[0018] SrCO 3 , MgO, BaCO 3 , (NH 4 ) 2 HPO 4 、Eu 2 o 3 According to the mass ratio of 1:1:1:1:1~1:1:1:2:1, put it into an agate mortar and grind it evenly to obtain the precursor;

[0019] Place the obtained precursor in a corundum crucible, put it into a muffle furnace for sintering under the reducing atmosphere provided by activated carbon;

[0020] The sample after sintering is taken out and ground;

[0021] After grinding, put it into the muffle furnace again for sintering, take out and grind after sintering to obtain single-matrix LED phosphor BaSrMg (PO 4 ) 2 :Eu 2+ .

Embodiment 1

[0023] Preparation of 10 g single-matrix LED phosphor BaSrMg (PO 4 ) 2 :Eu 2+ : 10g SrCO 3 , 10g MgO, 10g BaCO 3 , 10g (NH 4 ) 2 HPO 4 , 10g Eu 2 o 3 Put it into an agate mortar and grind it evenly to obtain a precursor; put the obtained precursor in a corundum crucible, put it into a muffle furnace under the reducing atmosphere provided by activated carbon, and the temperature of the muffle furnace is 10°C min -1 The temperature was raised to 800 °C at a constant temperature for 2 hours for sintering; the sintered sample was taken out and ground; after grinding, it was put into the muffle furnace for sintering again, and the muffle furnace was sintered at 10 °C min -1 The temperature was raised to 1000 ° C at a constant temperature for 2 hours. After sintering, it was taken out and ground to obtain a single-matrix LED phosphor BaSrMg (PO 4 ) 2 :Eu 2+ .

Embodiment 2

[0025] Preparation of 10 g single-matrix LED phosphor BaSrMg (PO 4 ) 2 :Eu 2+ : 10g SrCO 3 , 10g MgO, 10g BaCO 3 , 15g (NH 4 ) 2 HPO 4 , 10g Eu 2 o 3 Put it into an agate mortar and grind it evenly to obtain a precursor; put the obtained precursor in a corundum crucible, put it into a muffle furnace under the reducing atmosphere provided by activated carbon, and the temperature of the muffle furnace is 12°C min -1 The temperature was raised to 850°C at a constant temperature for 2.5 hours for sintering; the sintered sample was taken out and ground; after grinding, it was put into the muffle furnace for sintering again, and the muffle furnace was sintered at 12°C min -1 The temperature was raised to 1200 ° C at a constant temperature for 2.5 hours. After sintering, it was taken out and ground to obtain a single-matrix LED phosphor BaSrMg (PO 4 ) 2 :Eu 2+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com