Thermoplastic elastomer (TPE) alloy for nylon adhesive encapsulation and preparation method thereof

A technology of alloy and nylon, which is applied in the field of polymer materials, can solve the problems of poor adhesion between alloy materials and nylon coating, poor adaptability of TPE alloys, poor encapsulation effect, etc., and achieve good adhesion performance, excellent mechanical properties, Not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

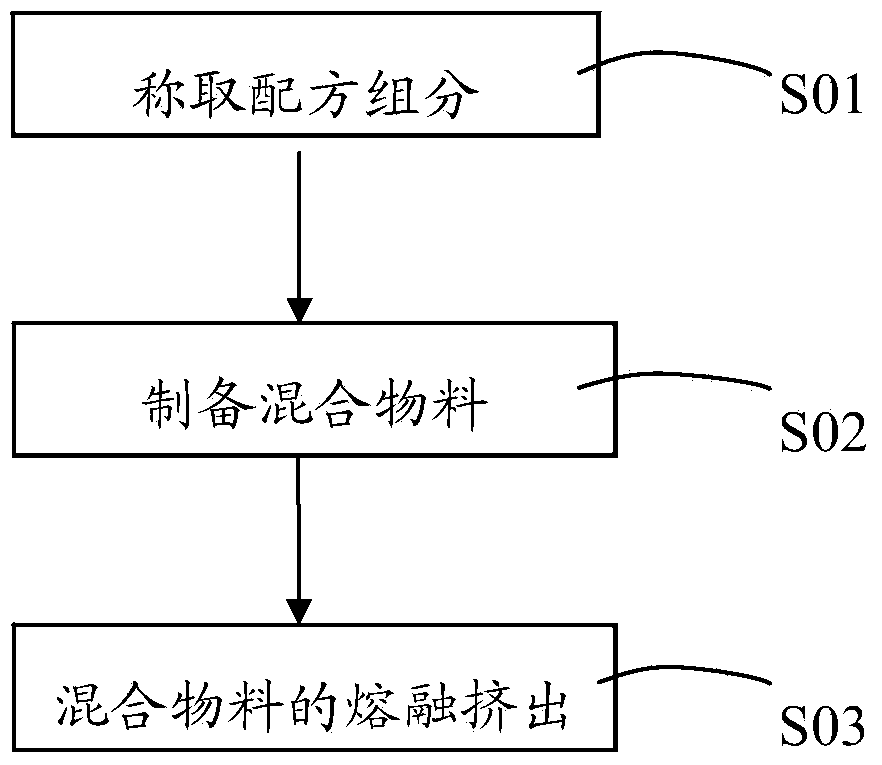

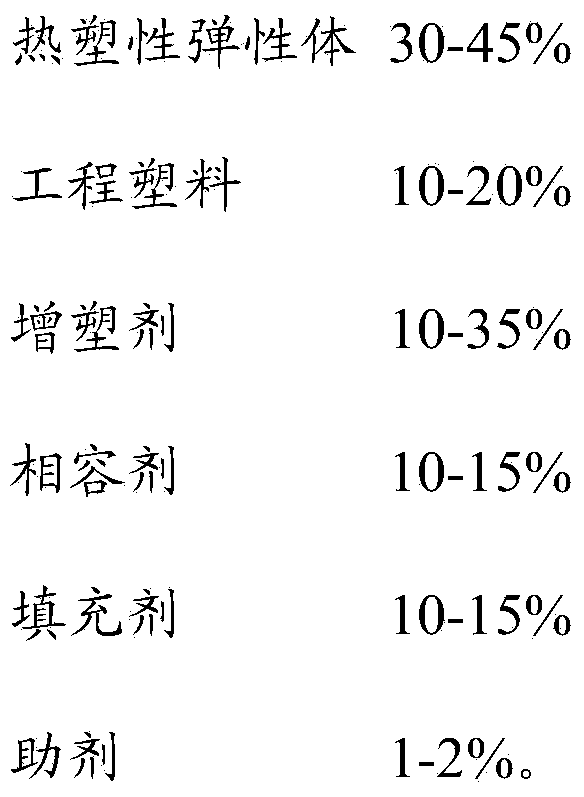

[0034] Correspondingly, the embodiment of the present invention also provides the preparation method of the above-mentioned TPE alloy for nylon adhesive encapsulation, and its process flow is as follows figure 1 shown. The method comprises the steps of:

[0035] S01. Weighing the formula components: Weighing each component according to the above formula for the TPE alloy used for nylon bonding and encapsulation;

[0036] S02. Preparation of mixed material: weighing each component in step S01 for mixing treatment to obtain mixed material;

[0037] S03. Melt-extrusion of the mixed material: melt-extrude the mixed material in step S02 to obtain the TPE alloy for nylon bonding and encapsulation.

[0038] Specifically, the formula of the TPE alloy used for nylon bonding and encapsulation in the above step S01 and the preferred content and types of each component in the formula are as described above, and will not be repeated here to save space.

[0039] In the above step S02, th...

Embodiment 1

[0045] The amount of each component used in the preparation of the nylon adhesive-encapsulated TPE alloy in this example is shown in Table 1 below.

[0046]Among them, the thermoplastic elastomer in Example 1 is a combination of styrene-based thermoplastic elastomer SEBS (Yuehua, YH503) and polyurethane thermoplastic elastomer TPU (Gaoding Chemical, EX-80A) at a weight ratio of 1:2 The engineering plastic is nylon 6 (BASF B35G3), the plasticizer is naphthenic oil, the compatibilizer is maleic anhydride grafted styrene block copolymer (SEBS-MAH, Kraton FG1901GT), and the filler is carbonic acid Calcium, auxiliary agent is anti-ultraviolet agent UV-329.

[0047] The preparation method of TPE alloy is as follows:

[0048] S11. Weigh thermoplastic elastomers, engineering plastics, plasticizers, compatibilizers, fillers and auxiliary agents according to the formula of Example 1 in Table 1;

[0049] S12. Weighing each component in step S11 for mixing treatment, and mixing uniforml...

Embodiment 2

[0052] The amount of each component of the TPE alloy used for nylon adhesive encapsulation in this embodiment is shown in Table 1, wherein,

[0053] The thermoplastic elastomer is a composition obtained by mixing styrene thermoplastic elastomer (SEBS, Yuehua YH503) and polyurethane thermoplastic elastomer (TPU, Gaoding Chemical EX-80A) at a weight ratio of 5:9, and the engineering plastic is polycarbonate Ester (Germany Bayer 2805), plasticizer is aromatic oil, compatibilizer is maleic anhydride grafted styrene block copolymer (SEBS-MAH, Kraton FG1901GT), filler is calcium carbonate, auxiliary agent is lubricant Ethylene bis stearamide.

[0054] The preparation method of TPE alloy is as follows:

[0055] S21. Take thermoplastic elastomers, engineering plastics, plasticizers, compatibilizers, fillers and auxiliary agents according to the formula of Example 2 in Table 1;

[0056] S22. Weighing each component in step S21 for mixing treatment, and mixing uniformly in a high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com