A Magnetic Suspension Supporting Structure of a Linear Feed Unit

A technology of linear feed and support structure, applied in the direction of electrical components, propulsion systems, magnetic attraction or thrust holding devices, etc., can solve the problem of reducing the effective support of the guide rail, affecting the processing and control accuracy of the feed unit, and reducing the rigidity of the guide rail structure and other problems, to achieve the effect of resisting adverse effects, improving processing accuracy and control accuracy, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

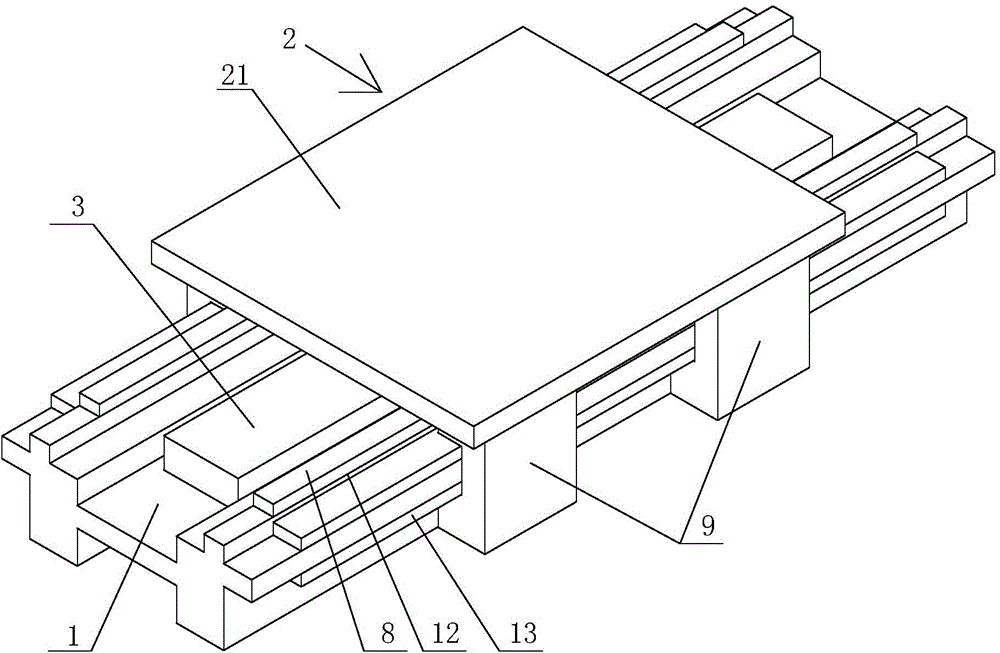

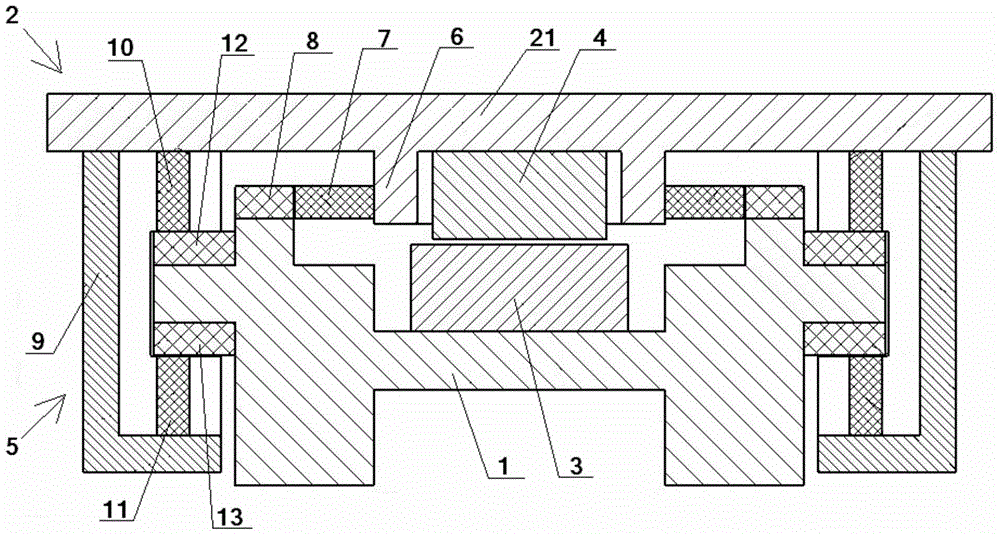

[0030] Such as Figures 1 to 4 As shown, the magnetic levitation support structure of the linear feed unit in this embodiment includes: a bed guide rail 1 fixed on the base, a workbench 2 set on the bed guide rail 1, and a linear motor stator 3 is installed on the bed guide rail 1 , the relative position of the workbench 2 is equipped with a linear motor mover 4 that cooperates with the linear motor stator 3, and the workbench 2 is composed of an upper workbench 21 and a supporting device 5 installed below the four corners of the upper workbench 21. The central position of the lower surface of the workbench 21 has a downwardly protruding rigid rectangular frame 6 arranged longitudinally (the rectangular frame 6 and the upper workbench 21 are integrally made of magnetically isolated aluminum material). The outer diameter of the rectangular frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com