scr denitrification device

A denitration and catalyst technology, applied in the field of flue gas denitrification, can solve the problems of insufficient space available for boilers and dust collectors, reduced catalytic effect, and inability to extract denitrification, etc., and achieves denitration treatment, good denitrification treatment, and increased catalytic efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

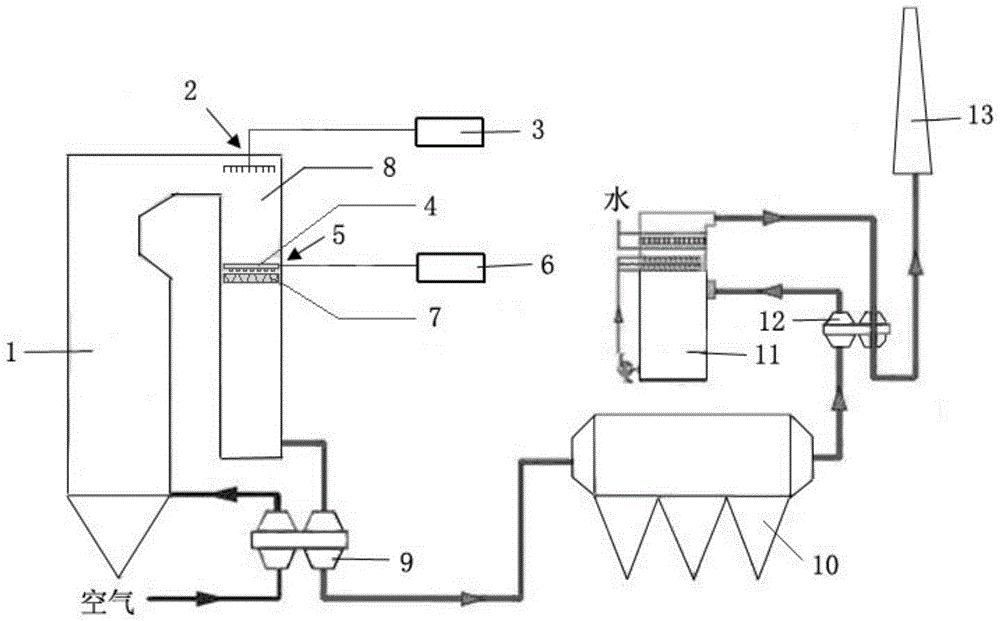

[0037] figure 1 A typical application of the SCR denitration device of the embodiment of the present invention is shown. like figure 1 As shown, the existing power plant generally includes a boiler 1, a flue 8 for exhausting flue gas, an ammonia gas storage tank 3, an air preheater 9, an electrostatic precipitator 10, an absorption tower 11, a heat exchanger 12 and a chimney 13, etc. . In a conventional SCR system, the SCR reactor is arranged between the boiler 1 and the electrostatic precipitator 10, and is arranged for a high-dust environment. The applicant found that the reason why the catalytic efficiency of the catalyst in the existing SCR reactor will drop rapidly is that, on the one hand, the large amount of soot carried in the flue gas in this area will block the pores of the catalyst; on the other hand, during the SCR operation process The catalyst is also subjected to the long-term action of alkali metals, water vapor, arsenic and other substances, resulting in ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com