Ion covalent organic framework catalyst, and preparation method and catalytic applications thereof

A covalent organic framework and ionization technology, applied in organic compound/hydride/coordination complex catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problems of poor catalytic effect of compounds and achieve high added value of products , good chemical stability, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of Example 1 Co(II)@TF-Py COF catalyst

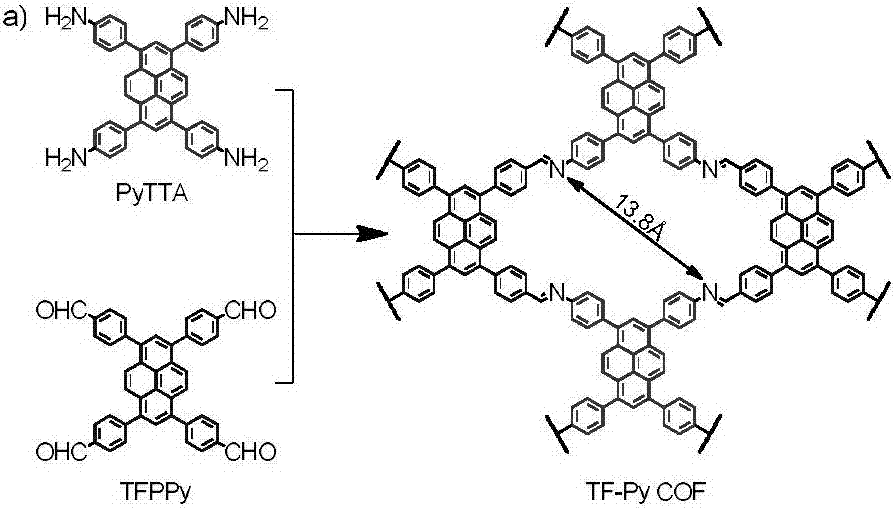

[0029] 1) Preparation of TF-Py COF

[0030] Take TFPPy (62.1mg, 0.1mmol) and PyTTA (56.7mg, 0.1mmol) in an ampoule, add 1mL 1,4-dioxane, 1mL mesitylene, 0.7mL N,N-dimethylacetamide , ultrasonically mix evenly, add 0.1mL 3M acetic acid solution, mix evenly; freeze the ampoule bottle in liquid nitrogen, evacuate to 20Pa, blow nitrogen gas, and seal the nozzle with flame; react at 140°C for 72 hours; the reaction is over Afterwards, the ampoule was naturally cooled to room temperature, and the product was washed with acetone and tetrahydrofuran to remove unreacted substrate; the washed product (TF-Py COF) was vacuum-dried at 80°C for 12 hours.

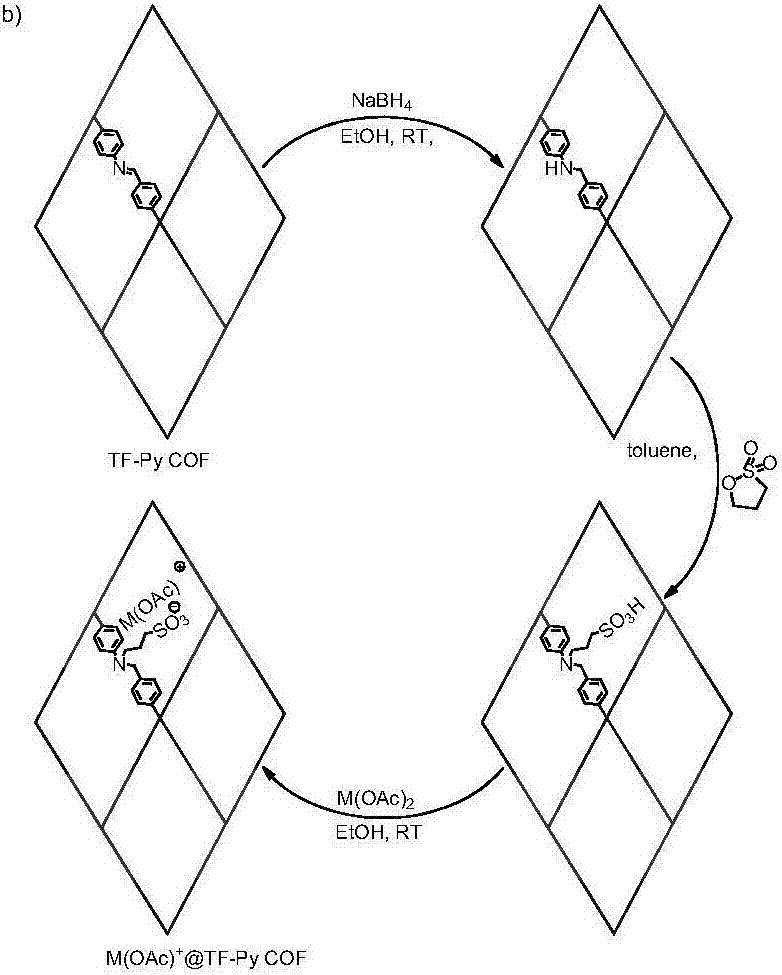

[0031] 2) Reduction of imine bonds in the TF-Py COF framework to secondary amine bonds

[0032] Take 30mg of TF-Py COF (about 0.03mmol) and place it in 30ml of ethanol solution with a concentration of 1M sodium borohydride, and stir for 30min at room temperature; wash the reduc...

Embodiment 2-4

[0037] Preparation of Example 2-4M(II)@TF-Py COF catalyst

[0038] Preparation method as described in Example 1, its difference is as follows:

[0039] Example

Embodiment 5

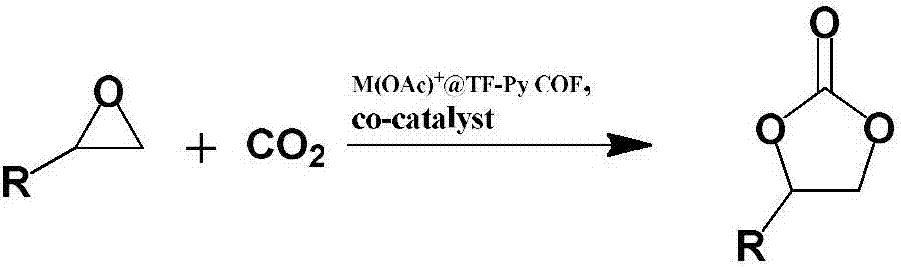

[0040] Example 5 Catalytic conversion of CO by Co(II)@TF-Py COF catalyst 2 experiment

[0041] Co(II)@TF-Py COF was used as a heterogeneous catalyst to catalyze the reaction of carbon dioxide and epichlorohydrin to generate cyclocarbonate compounds. At 100°C, under the condition of carbon dioxide pressure of 1Mpa, epichlorohydrin (0.587ml, about 7.5mmol), cocatalyst tetrabutylammonium iodide (5.5mg, about 0.015mmol), Co(II)@TF-Py COF (12.18mg, 0.0075mmol of cobalt element) mixed and stirred for 12h, The product and the catalyst are separated by filtration or suction filtration, and the liquid phase is the catalyzed target cyclocarbonate compound, with a yield of 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com