Lithium ion battery cathode material with two-shell layer structure and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied to battery electrodes, structural parts, circuits, etc., to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

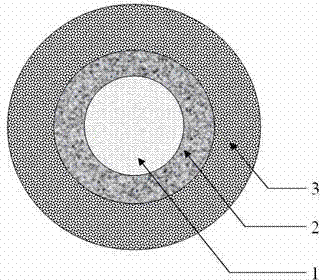

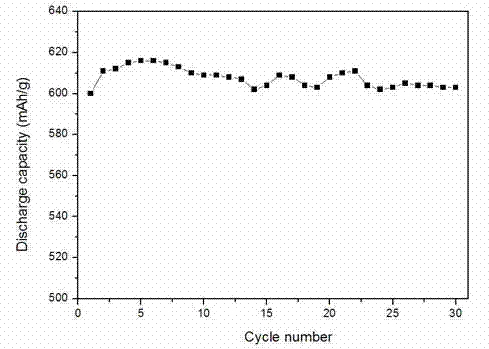

[0021] figure 1 As shown, commercial silicon powder with a particle size of 20nm and aluminum nitrate were dissolved in a deionized aqueous solution at a molar ratio of 1:0.35, and stirred at a high speed at a temperature of 80 o C, until the water is completely evaporated; the powder obtained in the above steps is placed in a tube furnace with argon protection for sintering, the sintering time is 3h, and the sintering temperature is 650 o C, carry out cooling at room temperature; then above-mentioned product and sucrose are mixed by dehydrated alcohol according to the ratio of mass ratio 1: 3.8, utilize high-energy ball mill to carry out ball milling, ball milling time is 10h; Finally ball milling gained slurry 100 o After C is dried, place it again in a tube furnace with argon protection for sintering for 5 hours, and the sintering temperature is 750 o C, after cooling at room temperature, the anode material with "silicon / alumina / carbon" double-shell structure can be obtain...

Embodiment 2

[0023] Dissolve commercial silicon powder with a particle size of 300nm and zinc nitrate in a deionized aqueous solution at a molar ratio of 1:0.05, and stir at a high speed at 120 o C, until the water is completely evaporated; the powder obtained in the above steps is placed in a tube furnace with nitrogen protection for sintering, the sintering time is 6h, and the sintering temperature is 300 o C, carry out room temperature cooling; Then above-mentioned product and grape are mixed by acetone according to the ratio of mass ratio 1: 2.5, utilize high-energy ball mill to carry out ball milling, ball milling time is 15h; Finally ball milling gained slurry 100 o After C drying, place it again in a tube furnace with nitrogen protection for sintering for 10 hours, and the sintering temperature is 600 o C, after cooling at room temperature, the anode material with "silicon / zinc oxide / carbon" double-shell structure can be obtained.

Embodiment 3

[0025] Dissolve commercial silicon powder with a particle size of 150nm and zirconium nitrate in a deionized aqueous solution at a molar ratio of 1:0.2, and stir at a high speed at a temperature of 100 o C, until all the water is evaporated; the powder obtained in the above steps is placed in a vacuum furnace for sintering, the sintering time is 5h, and the sintering temperature is 500 o C, then carry out room temperature cooling; The above-mentioned product and polyethylene are mixed by dehydrated alcohol according to the ratio of mass ratio 1: 2.2, utilize high-energy ball mill ball mill 11h; Ball mill gained slurry 100 o After drying at C, place at 700 o Sinter in a vacuum sintering furnace for 7 hours, and cool down at room temperature to obtain a negative electrode material with a double-shell structure of "silicon / zirconia / carbon".

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com