Thin film transistor, pixel unit, array substrate and display device

An array substrate and transistor technology, applied in transistors, electrical components, electrical solid devices, etc., can solve the problems of thin photoresist thickness, affecting TFT performance, changing TFT aspect ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

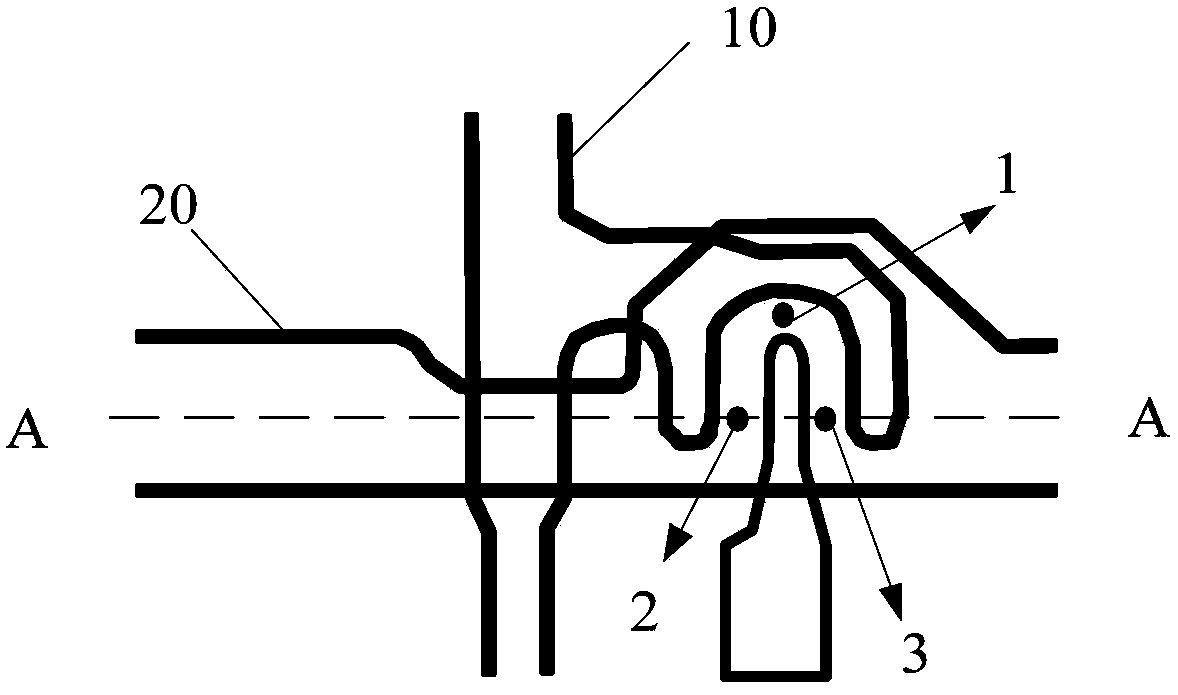

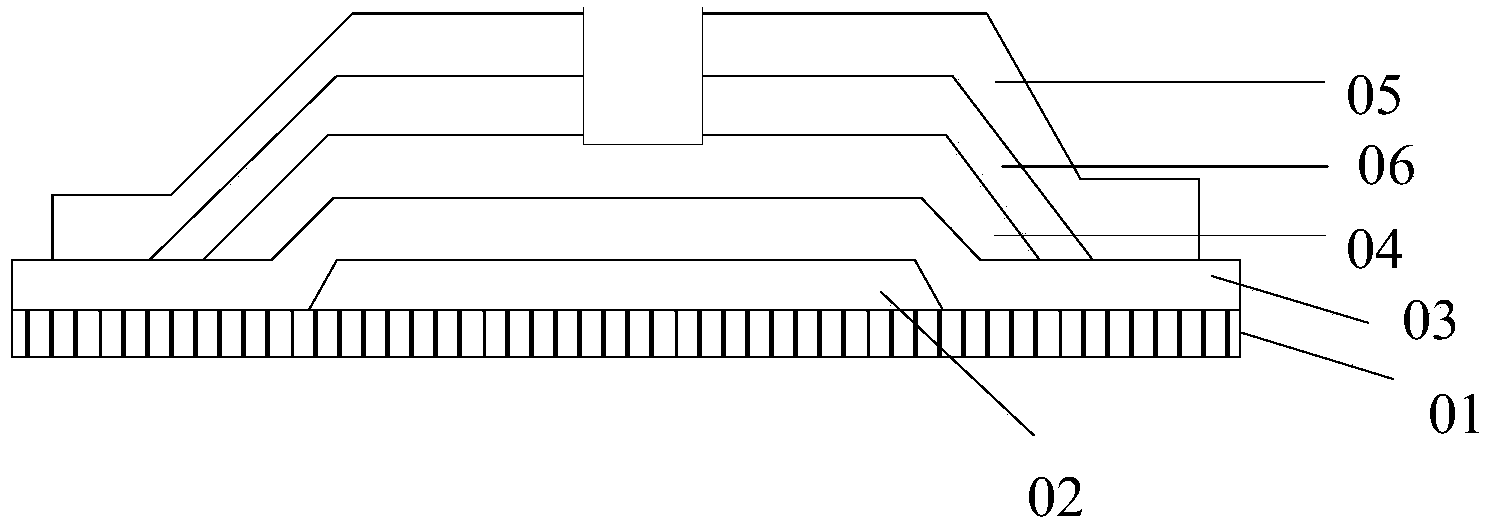

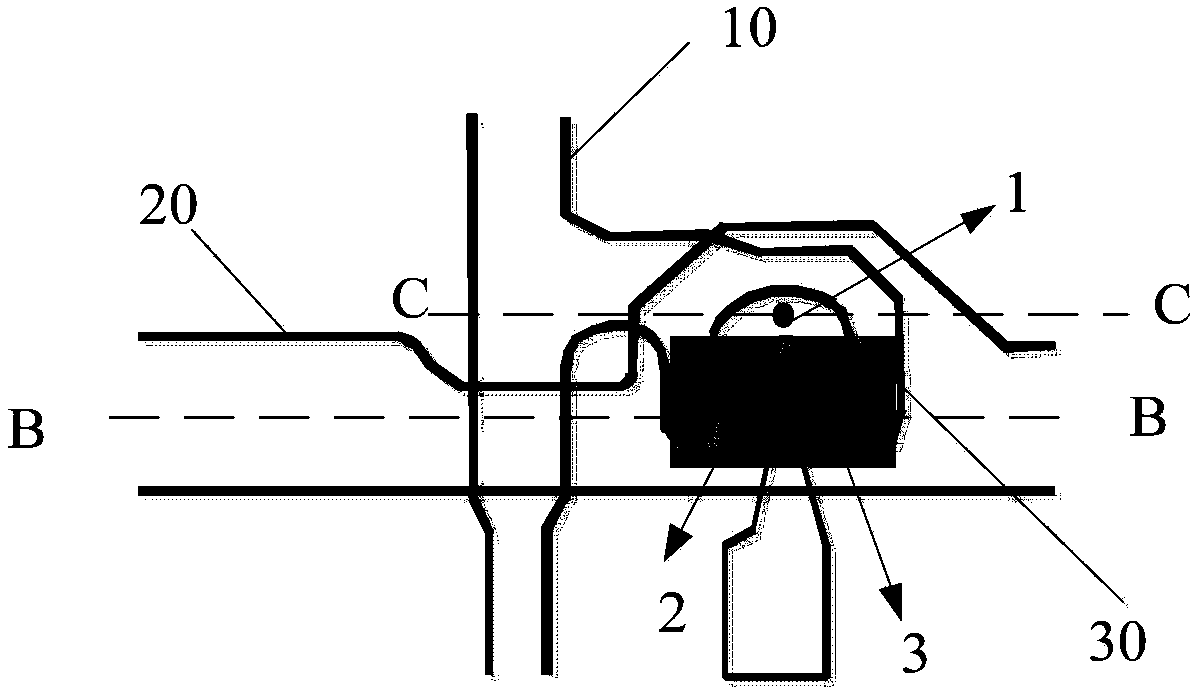

[0028] At present, in the TFT manufacturing process, a gate metal thin film is deposited on a substrate, and a gate electrode and a gate line are obtained through exposure and etching. The gate metal film is generally composed of multi-layer metal films. A specific mask is used to perform exposure and etching processes to form gate electrodes and gate line patterns on the substrate. The gate lines are formed in the pixel area along the horizontal direction.

[0029] Using the same manufacturing process, a gate insulating layer, an active layer, and a source-drain electrode layer are sequentially formed on the gate electrode. After coating the photoresist, the source-drain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com