Large-size light guide plate

A light guide plate, large-size technology, applied in the field of light guide plate, can solve problems such as unreachable use requirements, uneven brightness of light guide plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

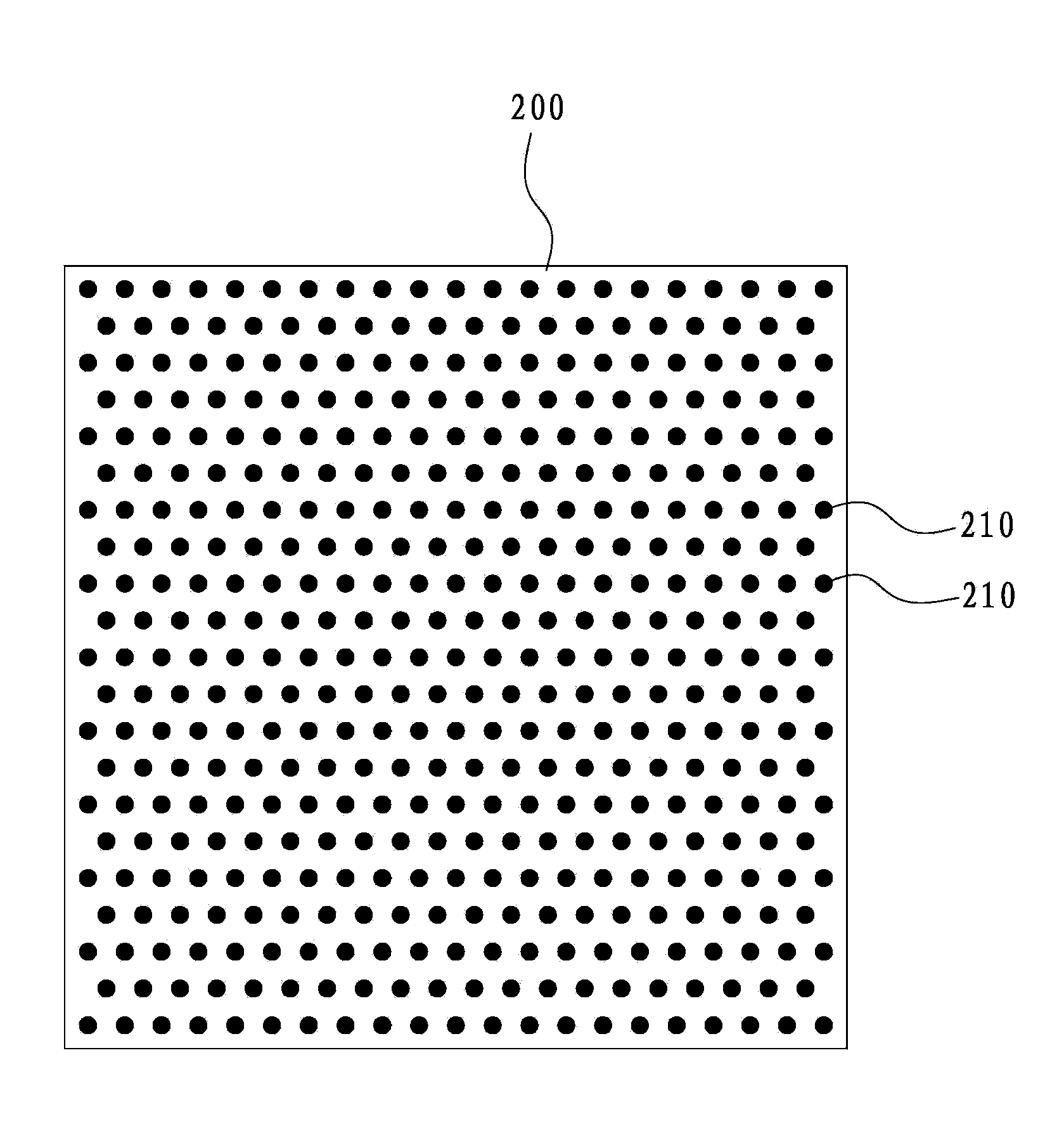

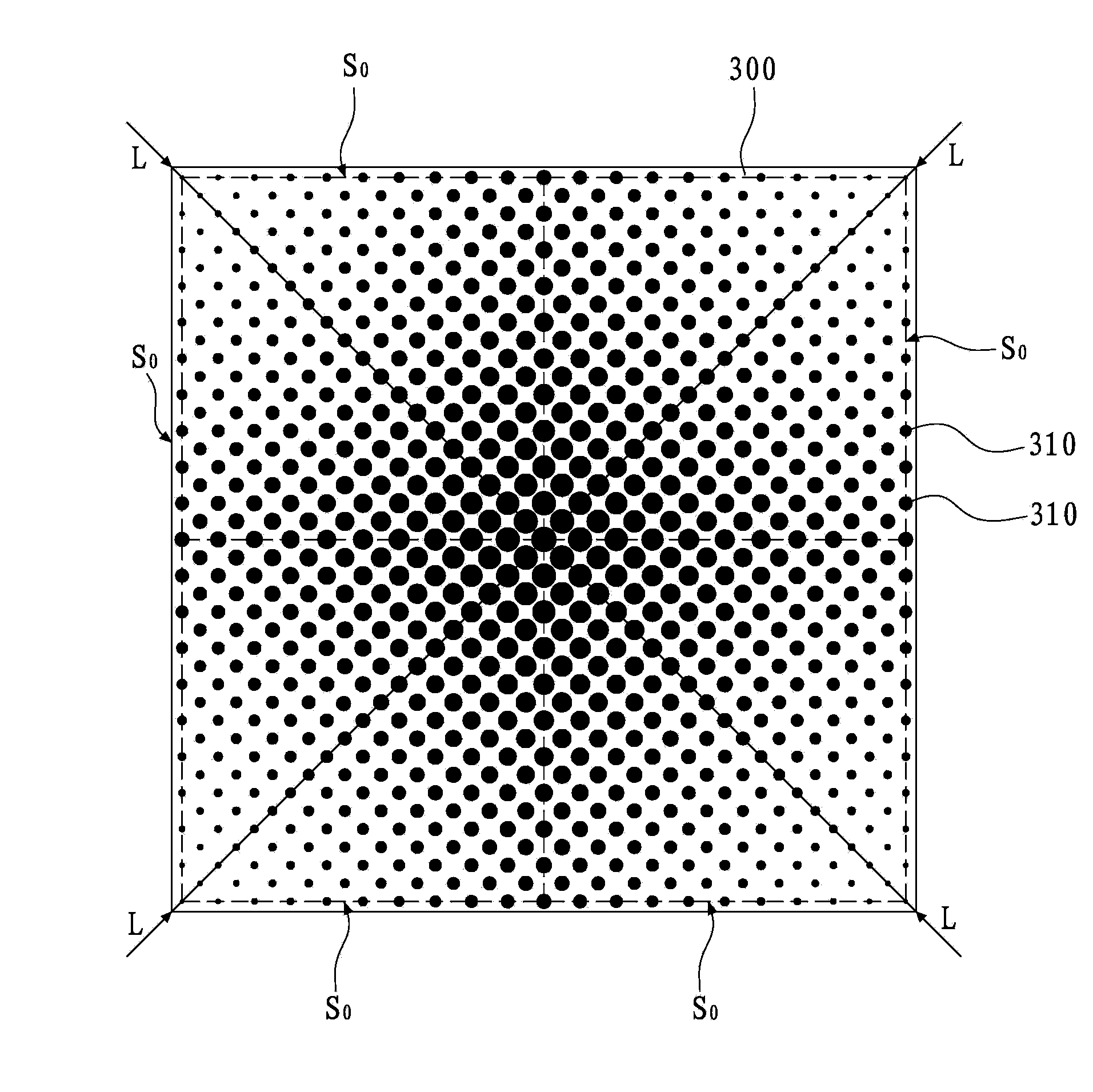

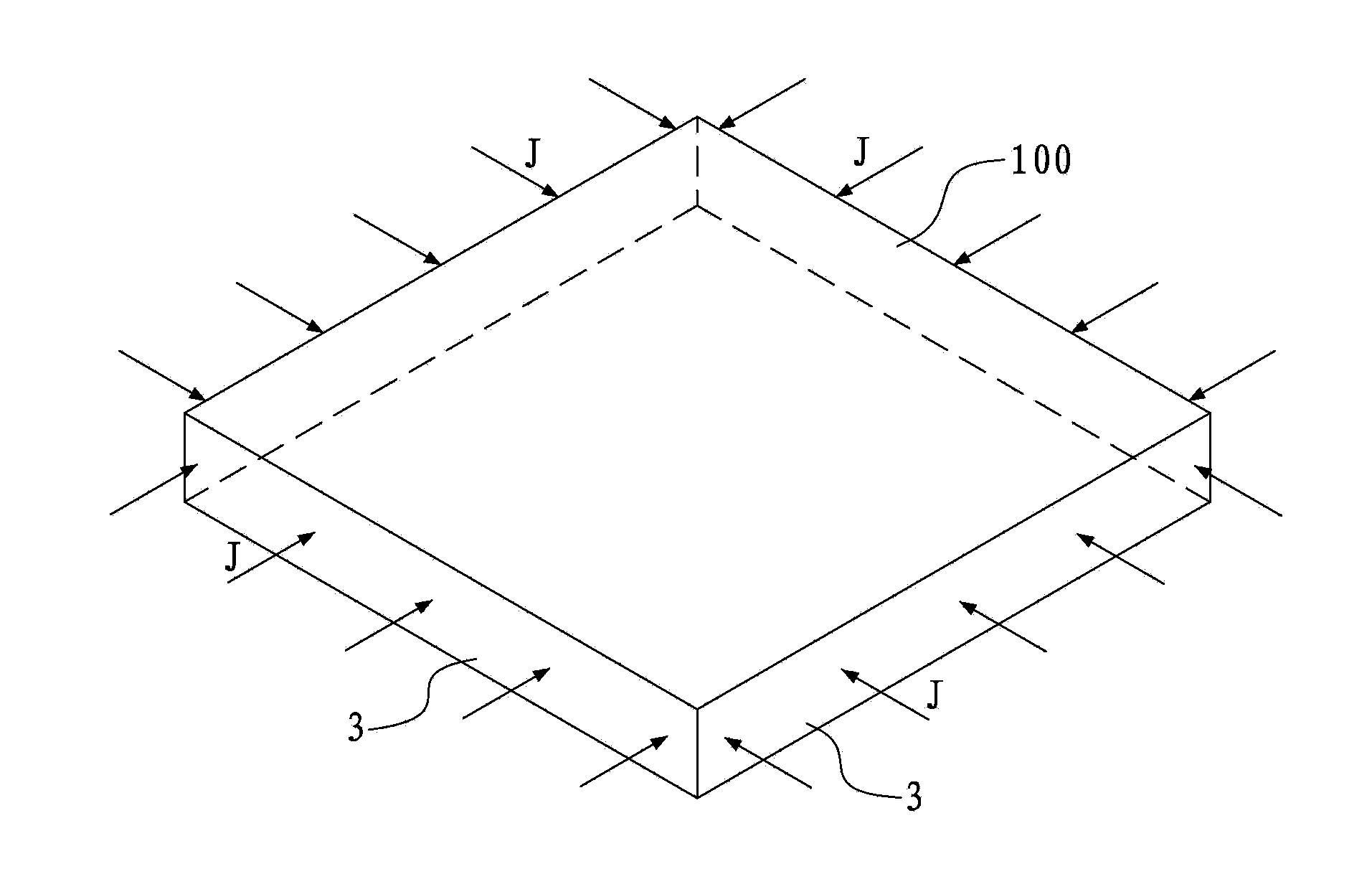

[0030] Such as image 3 with Figure 4 As shown, a large-sized light guide plate 100 involved in the present invention includes a plate body 1 and silk screen dots 2 on the reflective surface of the plate body. The plate body 1 has four sides 3 that allow light to enter. Please refer to image 3 As shown, light enters the four sides 3 at the same time, and the light enters along a direction perpendicular to the corresponding side.

[0031] see Figure 4 As shown, the plate body 1 is divided into four parts, specifically, it is formed by equal parts along the perpendiculars of the four sides of the reflective surface. Figure 4 Among them, the board body includes 4 parts in total, namely S1, S2, S3 and S4, and the screen printing dot 2 includes four dot matrix units with the same structure, which are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com