Gas-sensitive sensor based on cobaltosic oxide nanoneedle as well as preparation method thereof

A technology of cobalt tetroxide nanometer and cobalt tetroxide gas is applied in the field of nano-sensors, which can solve the problems of high optimal working temperature, cumbersome preparation process, poor working performance, etc., and achieve the effects of increasing surface active points, large electron mobility and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

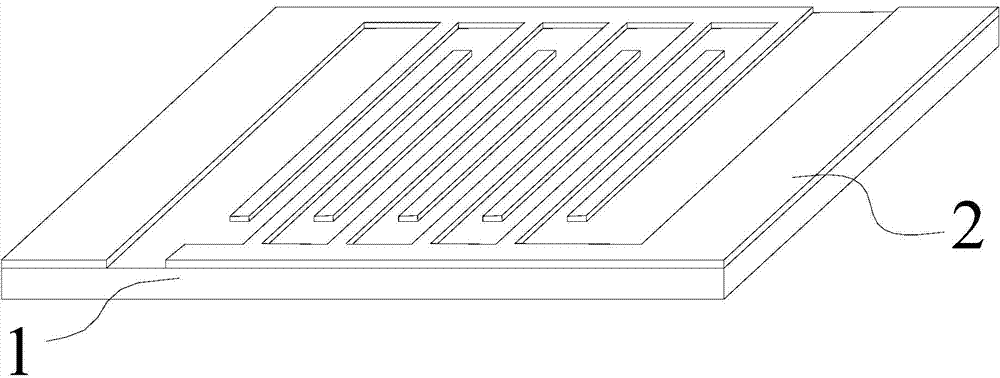

[0051] The gas sensor based on the cobalt trioxide nanoneedle of this implementation, such as figure 1 As shown, it includes an insulating substrate, a comb-shaped intersecting electrode layer and a cobalt tetraoxide gas-sensing sensing layer from bottom to top.

[0052] In this implementation:

[0053] The insulating substrate is a polycrystalline alumina ceramic sheet with an area of 2×1cm 2 .

[0054] The diameter of the cobalt trioxide nanoneedle array is 50nm-200nm, and the length is 10μm.

[0055] The material of the comb-shaped intersecting electrode layer is silver-palladium alloy, and the specific structure is as follows: figure 2 As shown, the thickness is 90nm-100nm, and the distance between adjacent intersecting electrodes is 100μm.

[0056] The preparation method of the cobalt trioxide nanoneedle gas sensor based on the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com