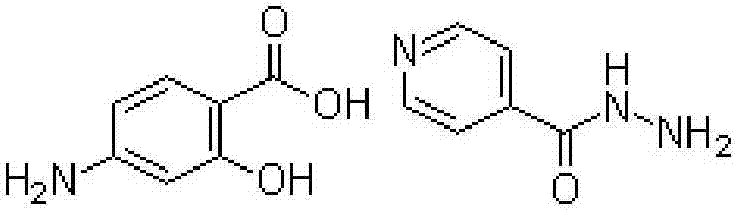

Preparation method of isoniazid para-aminosalicylate

A technology of isoniazid p-aminosalicylate and p-aminosalicylic acid, which is applied in the field of preparation of isoniazid p-aminosalicylate, can solve the problem of unqualified color, unqualified content and melting point, unqualified content and melting point, and easy Problems such as degradation and deterioration, to achieve the effect of fewer reaction operation units, good appearance crystal form, and easy control of the implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 56g of p-aminosalicylic acid and 50g of isoniazid to 300mL of purified water and 1000mL of ethyl acetate, stir, heat to 55-60°C, stir and react for 30 minutes, then cool down to 5-10°C, and keep the crystal for 60 minute. After filtration, the content of isoniazid p-aminosalicylic acid was 99.5%.

Embodiment 2

[0032] Add 56g of p-aminosalicylic acid and 50g of isoniazid to 300mL of water for injection and 500mL of methyl acetate, stir, heat to 70-100°C, stir and react for 30 minutes, then cool down to 15-20°C, and keep the crystal for 60 minute. After filtration, the content of isoniazid p-aminosalicylic acid was 99.3%.

Embodiment 3

[0034] Add 56g of p-aminosalicylic acid and 50g of isoniazid to 600mL of drinking water and 1100mL of ethyl n-propionate, stir, heat to 45-50°C, stir and react for 30 minutes, then cool down to 0-5°C, keep warm Crystals 60 minutes. After filtration, the qualified p-aminosalicylic acid isoniazid content is 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com