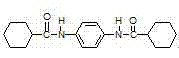

Preparation method of amide polypropylene beta crystal form nucleating agent by taking p-phenylenediamine as skeleton

A technology for p-phenylenediamine and amides, which is applied in the field of nucleating agent preparation, can solve the problems of expensive catalysts, the synthesis method is not specific enough, and is not economical enough, and achieves the effects of simple operation, convenient source of raw materials, and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] In a 500 ml reaction flask equipped with stirring, thermometer, reflux condensation tail gas absorption device and constant pressure dropping funnel device, add 150 ml of solvent chloroform, 10.8 g of p-phenylenediamine, and 16 g of acid-binding agent pyridine, and drop them under ice bath conditions. Add 30g of cyclohexanoyl chloride, after the dropwise addition, heat up to reflux temperature and react for 3h. After the reaction is terminated, add an appropriate amount of water to evaporate the solvent, wash and dry with hot water ethanol to obtain 31.7g of the product, with a melting point of 333.8°C, and the purity according to HPLC analysis is greater than 98%.

example 2

[0026] In a 2000 ml reaction flask equipped with stirring, thermometer, reflux condensation tail gas absorption device and constant pressure dropping funnel device, add 1000 ml of solvent chloroform, 64.8 g of p-phenylenediamine, and 96 g of acid-binding agent pyridine, and drop them under ice bath conditions. Add 180g of cyclohexanoyl chloride, after the dropwise addition, heat up to reflux temperature and react for 3h. After the reaction is terminated, add an appropriate amount of water to evaporate the solvent, wash and dry with hot water ethanol to obtain 195.7g of the product, with a melting point of 333.6°C, and the purity according to HPLC analysis is greater than 98%.

[0027] The structure of the nucleating agent is determined by infrared spectrum, elemental analysis and high-performance liquid chromatography analysis, and good effect is obtained when it is tried for polypropylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com