Piezoelectric electret material and preparation method thereof

A piezoelectric electret and electret technology, which can be used in the selection of materials for piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials. Limiting charge storage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

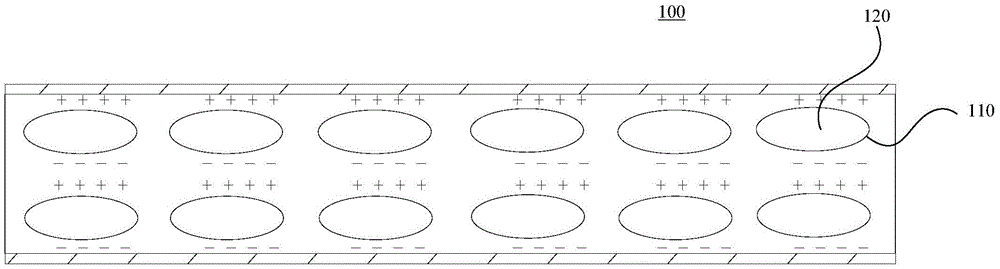

Image

Examples

preparation example Construction

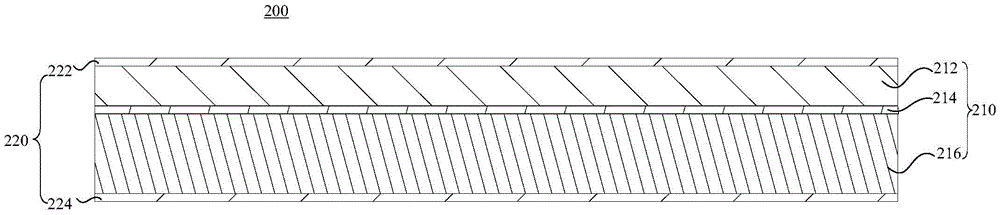

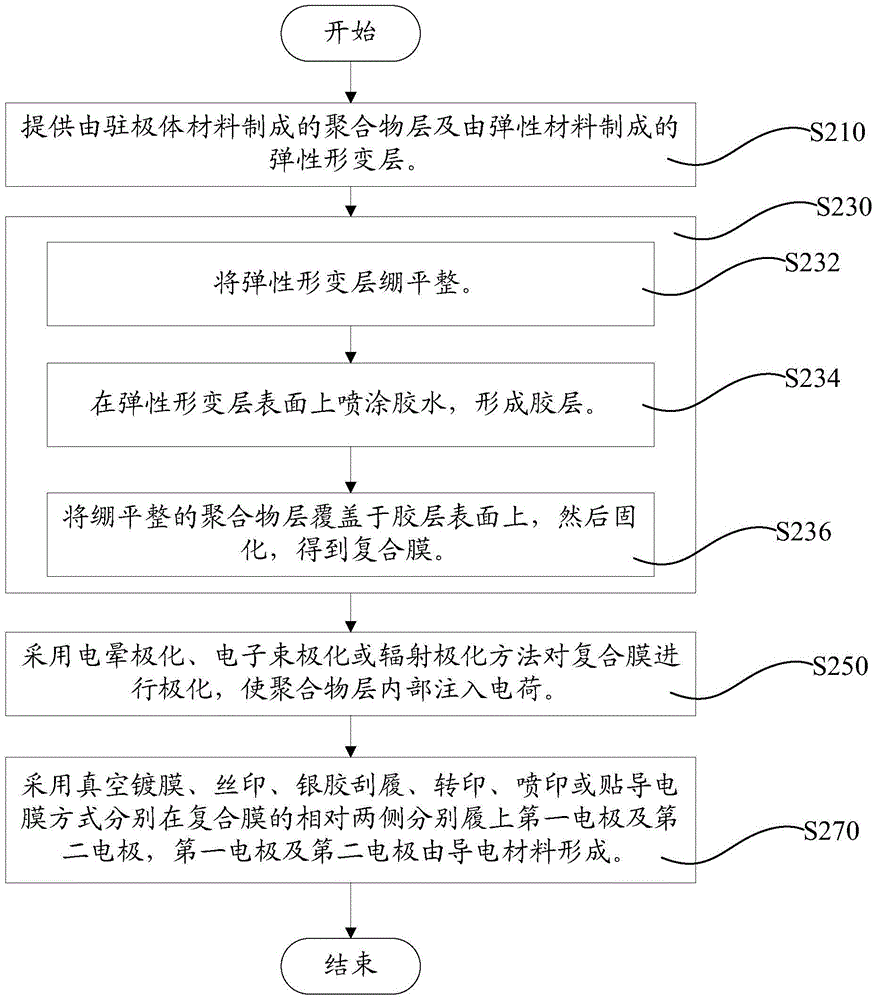

[0046] see image 3 , the preparation method steps of the piezoelectric electret material 200 in the above-mentioned first embodiment include the following steps:

[0047] Step S210 , providing the polymer layer 212 made of electret material and the elastic deformation layer 216 made of elastic material, wherein the elastic modulus of the elastic material is in the range of 0 MPa˜100 MPa.

[0048] Among them, the electret material can be selected from polytetrafluoroethylene (Polytetrafluoroethene, PTFE), fluorinated ethylene propylene copolymer (Fluorinatedethylenepropylene, FEP), polypropylene (Polypropylene, PP), perfluoroalkoxy resin (Polyfluoroalkoxy, PFA), Any one of polychlorotrifluoroethylene (PCTFE), polyvinylidene fluoride (PVDF) or polyethylene naphthalate (polyethylenenaphthalate, PEN). The thickness of the polymer layer 212 may range from 0.1 μm to 2000 μm. For example, it may be 25 μm.

[0049] The elastic material of the elastic deformation layer 216 is selec...

Embodiment 1

[0077] Preparation of piezoelectric electrets with PET / ePTFE (porous polytetrafluoroethylene, a type of polytetrafluoroethylene) structure

[0078] A composite membrane made of ePTFE material is provided. In this embodiment, ePTFE acts as both a polymer layer and an elastic deformation layer, and the outer surface of the composite membrane formed by the ePTFE material has a through-hole structure. The film thickness formed by ePTFE is 50 μm. An auxiliary layer made of PET material is formed between the ePTFE and an electrode, so that the electrode can more easily fit on the surface of the ePTFE film. The ePTFE film was polarized by the gridless corona polarization method with a polarization voltage of 30kV, and the polarization time was 1min. A first silver electrode and a second silver electrode with a thickness of 100 nm were respectively formed on the surface of the ePTFE film and the PET film by means of screen printing.

Embodiment 2

[0080] Preparation of piezoelectric electret materials with FEP / EPP structure

[0081] Provided is a polymer layer formed of FEP material with a thickness of 25 μm, and an elastically deformable layer formed of EPP material with a thickness of 50 μm. The bonding method is used to complete the polymer layer formed by FEP material and the elastic deformation layer formed by EPP material by using equipment and fixtures. Specifically, first stretch the EPP elastic deformation layer flat, then spray AB glue on the surface of the EPP elastic deformation layer, then cover the stretched FEP polymer layer on the surface of the AB adhesive layer, and then cure it at a temperature of 100°C. The curing time is 60min. The FEP polymer layer was polarized by a gridless corona polarization method with a polarization voltage of -30kV, and the polarization time was 1min. A first silver electrode and a second silver electrode with a thickness of 150 nm were respectively formed on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| charge density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com