Method for forming complementary metal oxide semiconductor tube

A technology of semiconductor tubes and oxides, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of unstable performance of semiconductor tubes, and achieve the effect of stable threshold voltage and stable device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

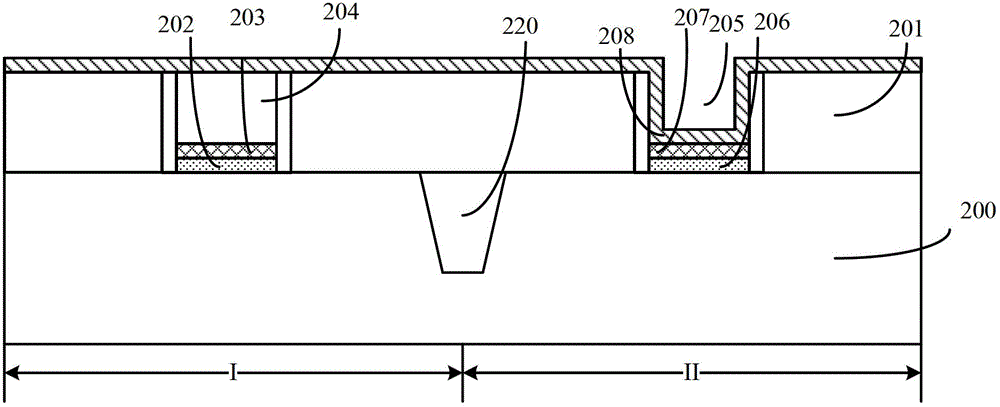

[0031] As mentioned in the background art, the performance of CMOS transistors formed in the prior art is not stable.

[0032] The research of the inventors found that the material used to form the gate electrode layer of the complementary metal oxide semiconductor transistor in the prior art is aluminum, and when the aluminum material is deposited in the opening for forming the gate electrode layer, due to the deposition of the opening The size of the window is small and it is easy to generate defects. Therefore, after the deposition process, thermal annealing is required to reflow the liquid aluminum to make the formed gate electrode layer dense; however, the liquid aluminum during the thermal annealing process is easy to penetrate into the work function layer, and the work function of the aluminum is low; because in the prior art, the material of the gate electrode layer of the PMOS tube is the same as that of the gate electrode layer of the NMOS tube, when aluminum penetrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com