Photoresist stripping agent

A technology of photoresist and stripper, which is applied in the processing of photosensitive materials, etc. It can solve the problems of easily changing composition and corrosion of metal wiring, etc., and achieve the effect of excellent photoresist stripping property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 chloride 1-hydroxyethyl-3-hexadecyl imidazole

[0036] Mix 1.79 g of imidazole and 3.8 mL of hexadecane bromide (the molar ratio of substances is 2:1) in 35 mL of ethyl acetate, stir for 10 minutes with magnetic force and mix well. Pour the mixture into a polytetrafluoroethylene liner with a capacity of 60mL, seal the polytetrafluoroethylene liner into a stainless steel reactor, and put it into a digital oven, heat it from room temperature to 120°C for 16 hours, and then cool it naturally to room temperature. Then the mixture was filtered to take out the filtrate, washed several times with distilled water to remove the imidazole that did not participate in the reaction, and the solvent ethyl acetate was evaporated with a rotary evaporator, and the resulting product 1-hexadecyl imidazole was dried in a vacuum oven at 70°C for 12 hours to constant weight. Obtain pale yellow liquid, weigh the product, mix 2.9g of 1-hexadecyl imidazole and ...

Embodiment 2

[0037] Preparation of Example 21-(2-amino-thiourea ethyl)-2-oleic acid imidazoline

[0038] Mix 0.2 mol of oleic acid (Tianjin Bodi Chemical Co., Ltd., analytically pure) with 0.24 mol of diethylenetriamine (Tianjin Bodi Chemical Co., Ltd., analytically pure), and add a mass fraction of 25% to 35% % xylene (Laiyang Kangde Chemical Co., Ltd., analytically pure) was used as a water-carrying agent, and then the mixed solution was continuously stirred, while heating at a uniform speed to 415K-435K for amide dehydration, and the amide was obtained after 2.5 hours of reaction. On this basis, continue to heat up to 495-515K for cyclodehydration, react for 2 hours and cool to 395K, use a vacuum pump to distill under reduced pressure for 0.5 hours to remove xylene and unreacted diethylenetriamine, and finally use iso Propanol (fine chemical plant of Laiyang Economic and Technological Development Zone, analytically pure) recrystallizes the crude product to obtain 1-(2-aminoethyl)-2-olei...

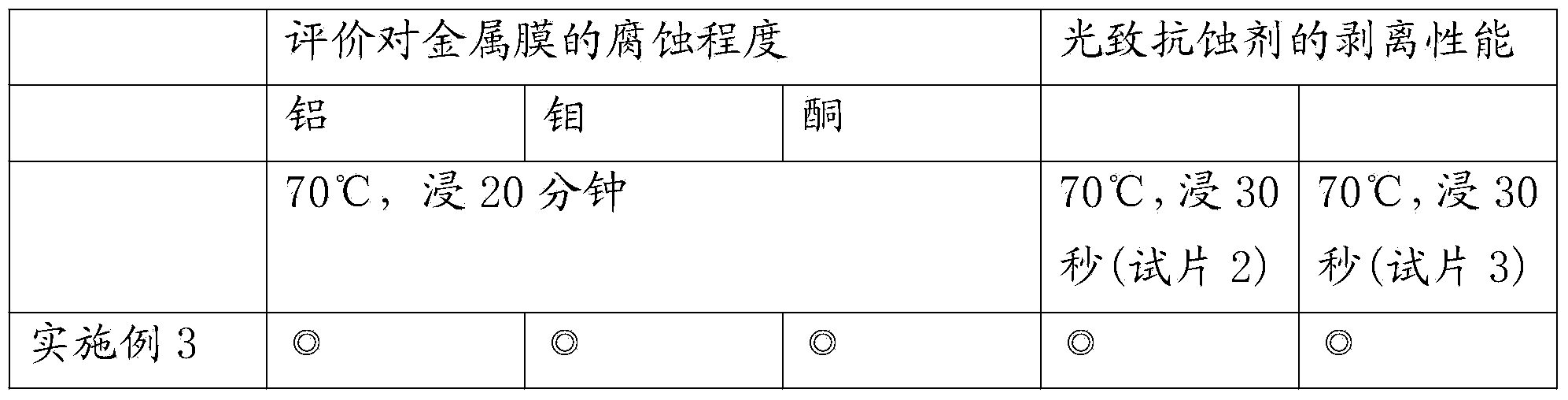

Embodiment 3

[0040] With N-ethyl ethyl carbamate 25g, ethylene glycol monobutyl ether 8g, gallic acid 4g, organic solvent and the chloride 1-hydroxyethyl-3-hexadecylimidazole 4g that embodiment 1 prepares, embodiment 4 g of 1-(2-amino-thiourea ethyl)-2-oleoimidazoline prepared in 2 were mixed and stirred until clear to obtain a stripping agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com