Large-sized concrete automatic temperature control and maintenance device and method

A large-volume concrete and automatic temperature control technology, which is applied in construction, infrastructure engineering, etc., can solve problems such as concrete cracks and achieve the effect of increasing the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

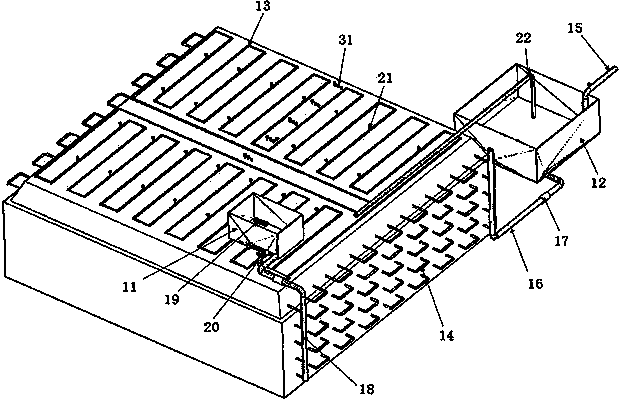

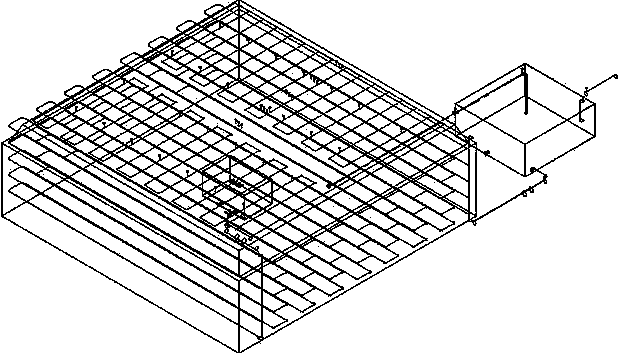

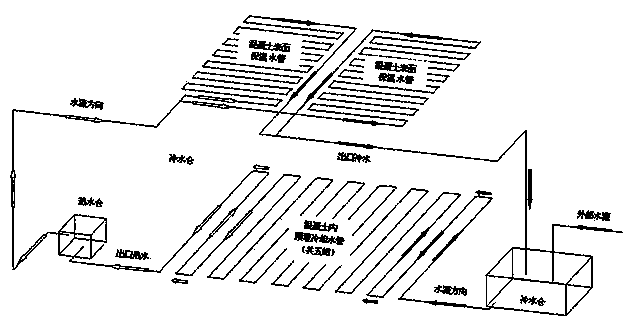

[0062] The main implementation method of mass concrete temperature control device of the present invention is as follows:

[0063] 1. During the construction of the blast furnace foundation, according to the label, volume, area and thickness of the concrete to be poured, the internal cooling pipe (that is, the heat dissipation water pipe and the cooling water pipe 14) (Dφ50 steel pipe) is pre-buried according to the actual needs, according to the vertical and horizontal distances The requirement that they are all less than 1m is evenly distributed inside the concrete, and connected in series with the φ219 main pipe outside the pouring body.

[0064] 2. Pre-embed the temperature measuring device inside the foundation. Starting from the center of the blast furnace, a total of 5 temperature monitoring stations are arranged in the horizontal direction, and each temperature monitoring station is equipped with 3 temperature monitoring point probes in the vertical direction (the embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com